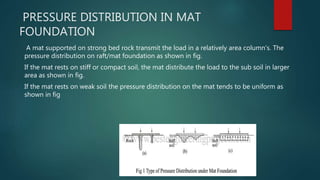

This document discusses mat and pile foundations. It describes mat foundations as thick reinforced concrete slabs that transmit loads from columns or walls into the soil. Common uses include supporting storage tanks and industrial equipment. It then discusses different types of mat foundations and how load is distributed depending on soil conditions. The document also outlines the typical procedures for constructing a mat foundation, including soil testing, excavation, reinforcement, forming, and curing. Pile foundations are described as using deep foundations when soil bearing capacity is low. Types of piles are classified based on function, material, and installation method. Factors for selecting the appropriate pile type include loads, soil conditions, structure type, and costs.