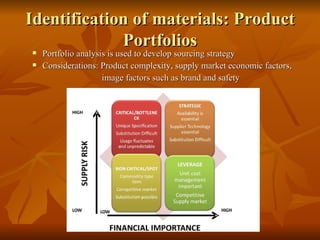

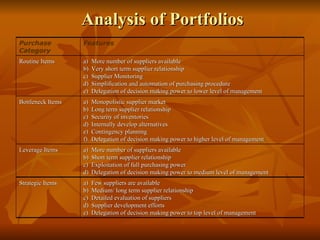

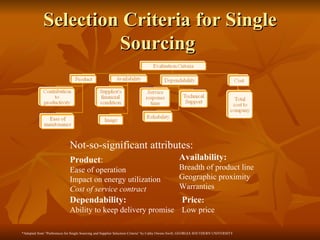

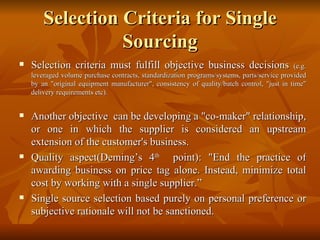

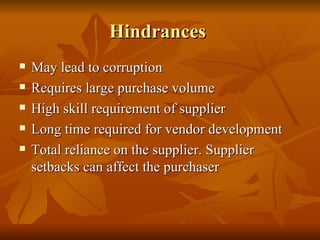

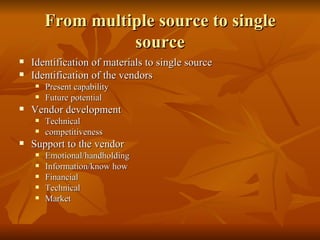

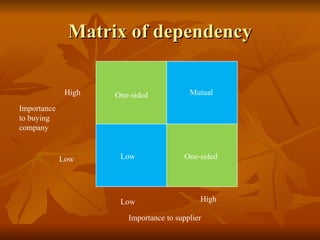

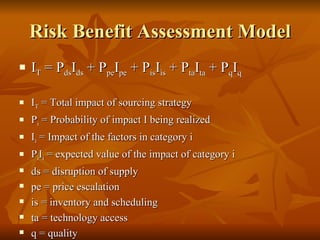

The document discusses single sourcing as a sourcing strategy. It identifies the key advantages as better pricing through higher volumes and better quality through continuous improvements with suppliers. Some disadvantages include potential price escalation and default risk if relying solely on one supplier. The document provides criteria for selecting a single source supplier, such as quality, delivery performance, and price. It also discusses moving from multiple sources to a single source and performing a risk/benefit assessment when considering this change.