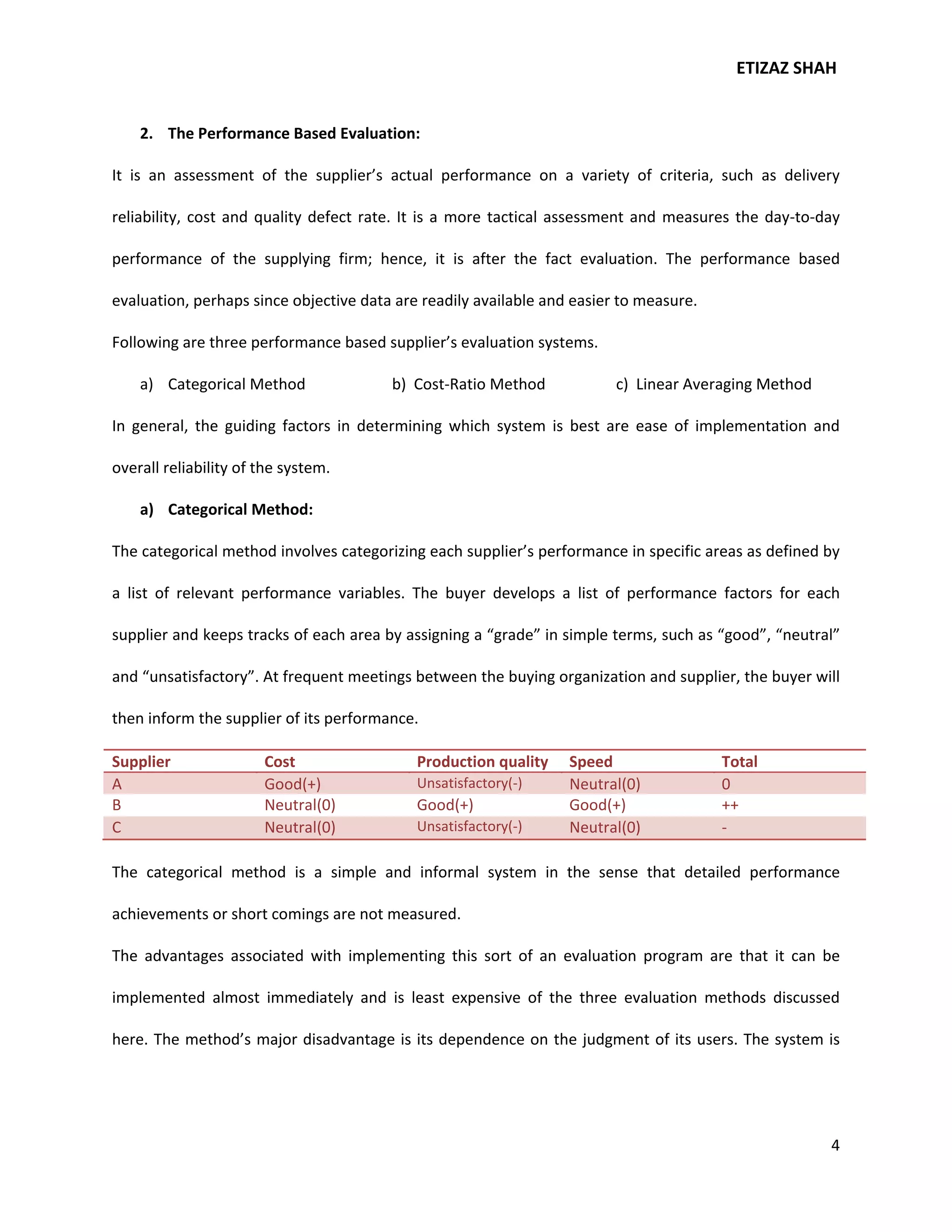

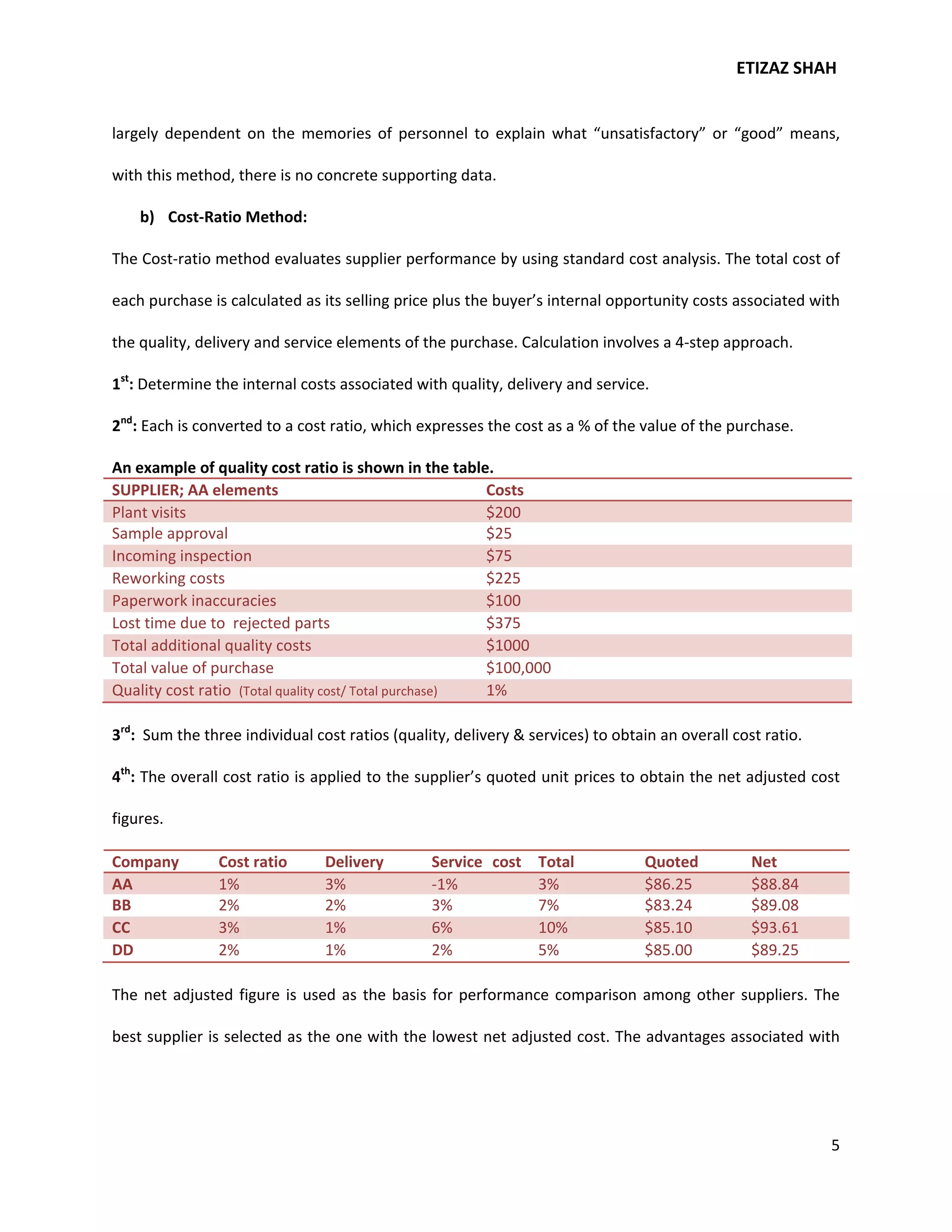

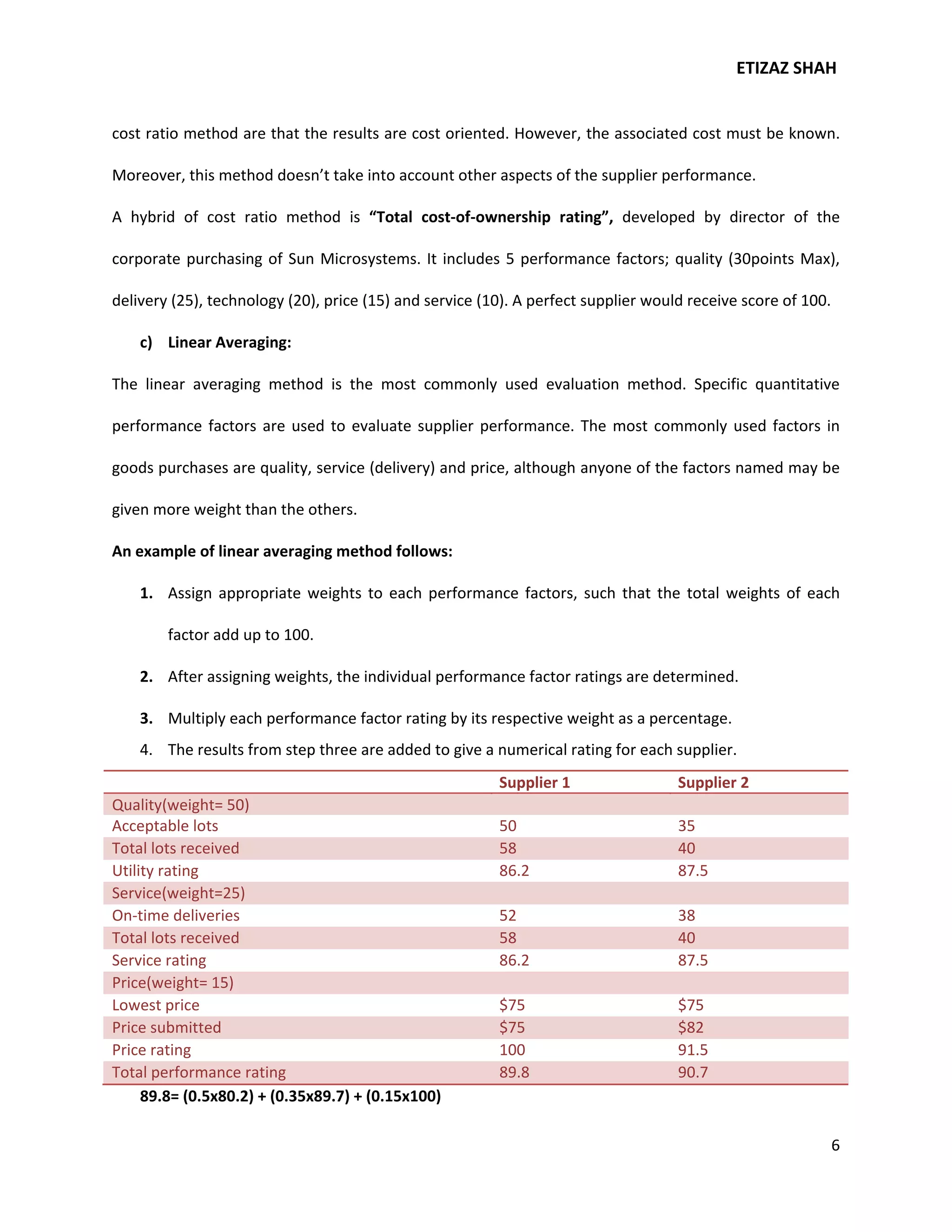

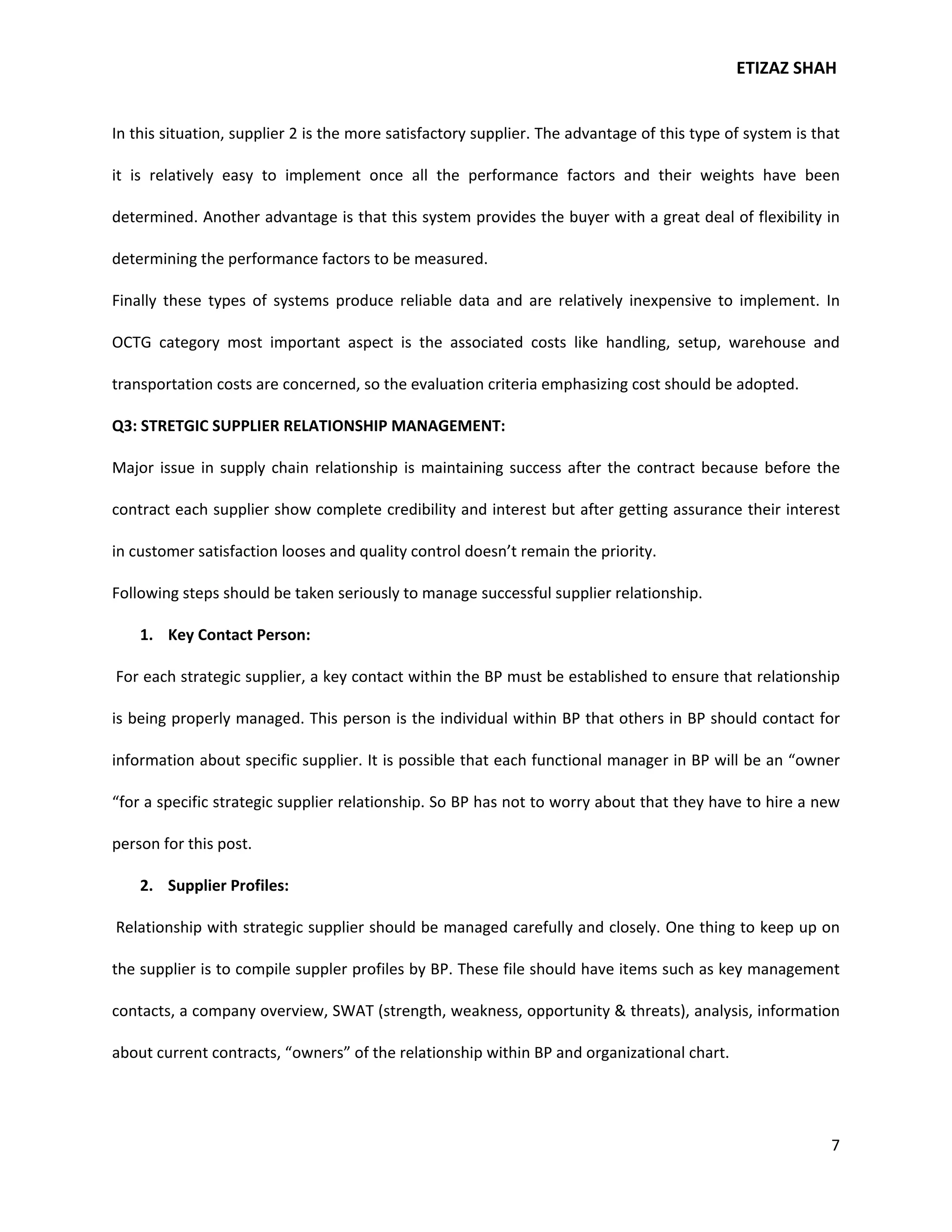

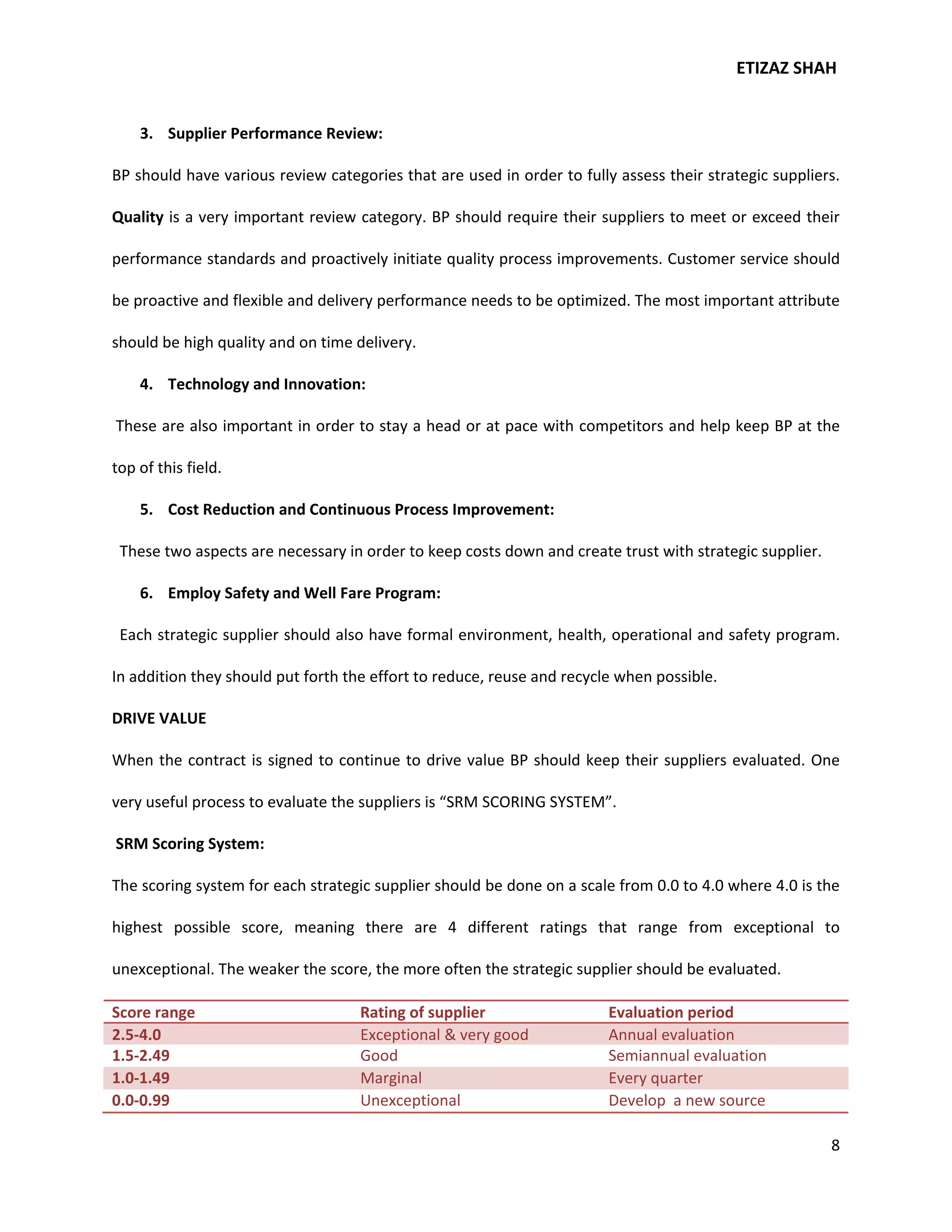

The document discusses developing a strategic sourcing plan for oil country tubular goods (OCTG) suppliers for BP. It outlines key factors to consider like customer requirements, supplier capabilities, and cost effectiveness. It also discusses the benefits of single versus multiple sourcing, criteria for evaluating suppliers, developing strategic supplier relationships, and managing suppliers that do not meet standards. The document provides a detailed analysis of sourcing strategies and supplier evaluation methods to help BP develop an optimal sourcing plan for OCTG suppliers.