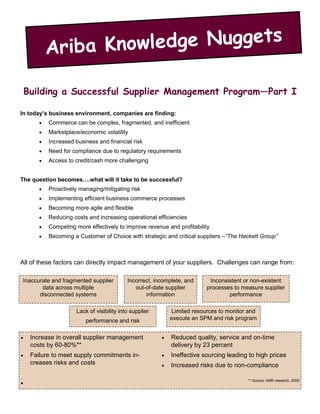

This document discusses building a successful supplier management program. It outlines some of the challenges companies face today such as economic volatility and increased business risk. It then discusses how proactively managing risk, implementing efficient processes, and becoming more agile can help companies address these challenges. The document also summarizes research finding that supply chain risk is increasing and more formal risk management programs are needed. It argues that technology, capabilities, content and community all play important roles in structuring effective supplier management programs.