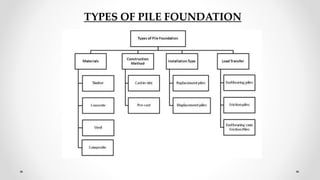

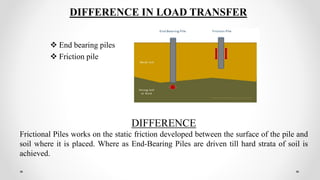

The document provides information about pile foundations and their construction process. It states that pile foundations involve long concrete cylinders that are driven into the ground to support structures built above weak soil layers. It describes the two main types of pile foundations as end bearing piles and friction piles. It then explains the multi-step process of constructing pile foundations which involves casting piles on site, using a pile driver to vertically insert the piles into the ground until refusal.