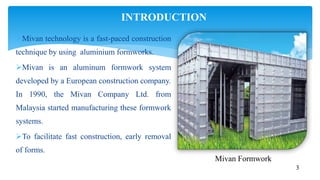

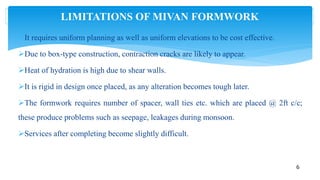

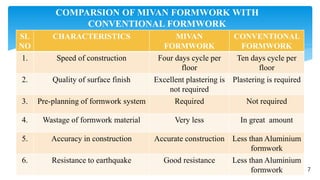

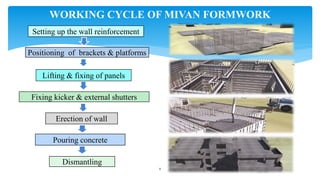

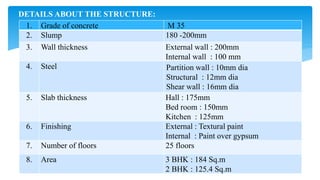

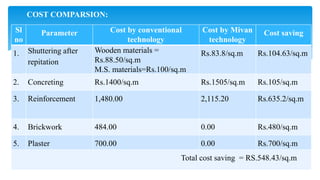

This document discusses Mivan formwork technology. Mivan formwork uses pre-engineered aluminum forms for constructing walls and slabs in a single operation. It allows for fast construction with good quality finishes. Some advantages are speed of construction, accuracy, reusability of forms. Limitations include need for uniform planning and risk of cracks. A case study compares costs of Mivan technology to conventional construction, finding savings of around Rs. 548/sqm with Mivan. In conclusion, Mivan is a cost-effective tool that can maximize use of modern techniques for large housing projects.

![14

REFERENCES

Ketan Shah., (2005),“Modular formwork for faster, economical and quality

Construction”, Indian Concrete Journal, Vol-79, pg. 6-23.

Kushal Patil., Ajitkumar Jadhav., Nikhil Shingat.,(2015),“Mivan Technology”,

International Journal of Engineering and Technical Research (IJETR) ISSN: 2321-0869,

Volume-3, Issue-6.

Mr. Shankar Bimal Banerjee., Mr. Pawan Dilip Barhate., Mr. Vipul Pradip Jaiswal.,

(2015),“Mivan Technology”, Novateu Publications International Journals Of Innovation In

Engineering Research And Technology [IJIERT], Volume 2, Issue 3.

Patil R.S., Pawale D.B., Tambe H. D. and Pawar P.D., Wakchuare A.V., (2016),“Mivan

Technology Using Aluminium Formwork”, International Journals Of Engineering

Sciences & Management, ISSN 2277 – 5528, Impact Factor- 3.145.](https://image.slidesharecdn.com/404128086-mivan-ppt-0-pptx-240225152645-bae3646c/85/404128086-mivan-ppt-0-pptx-pptx-14-320.jpg)