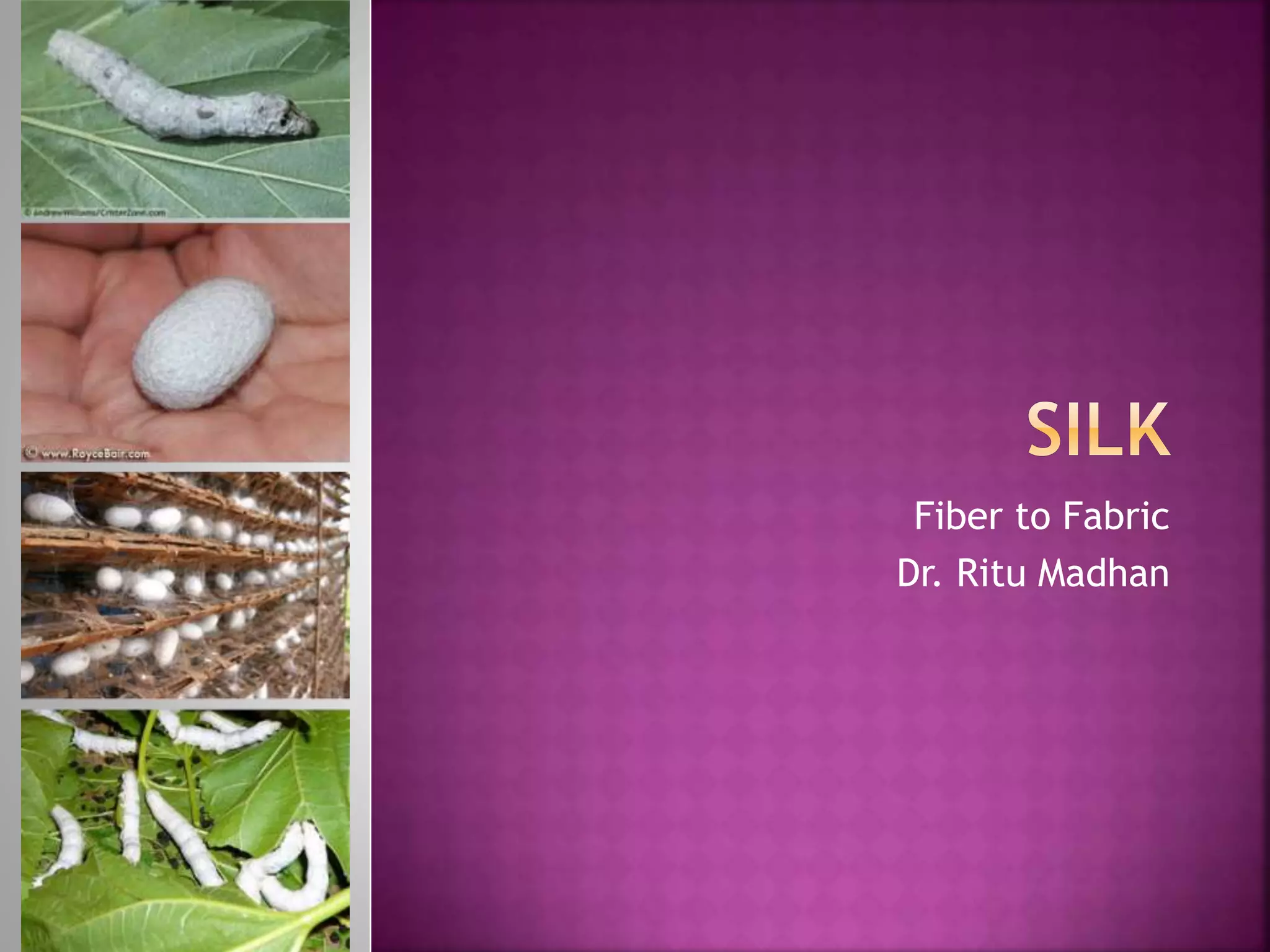

The document outlines the history and process of silk production, originating from ancient China where silkworms were first cultivated. It describes sericulture, the lifecycle of silkworms, and various types of silk, including mulberry, tassar, muga, and eri silk, along with their properties and uses. Additionally, the document details the physical characteristics of silk, its processing methods, and care requirements.