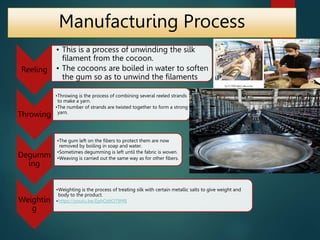

This document discusses the properties, production, and uses of silk as a textile fiber, detailing the lifecycle of the silkworm and the manufacturing processes involved in transforming silk from cocoon to fabric. It covers the physical, thermal, and chemical characteristics of silk, highlighting its strength, elasticity, and luxurious appearance. Additionally, it describes various applications of silk in fabrics suitable for different occasions.