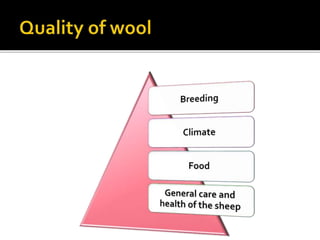

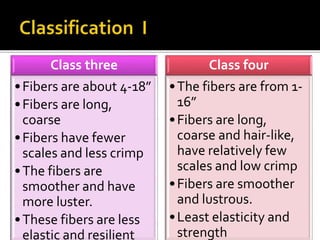

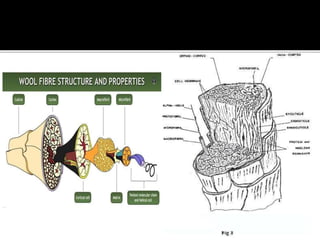

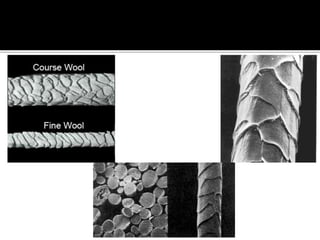

The document outlines the history and characteristics of wool production, detailing the types of wool fibers, their qualities, and processes involved in wool preparation. It describes various kinds of sheep wool, the classification based on fiber quality, and the steps from shearing to recycling, including scouring and drying. Additionally, it covers the properties of wool, its care, and the challenges it faces from environmental factors and pests.