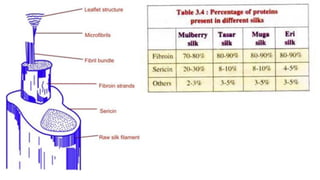

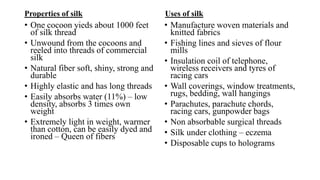

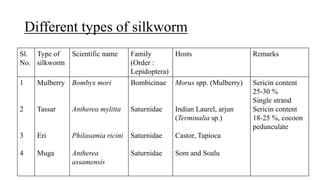

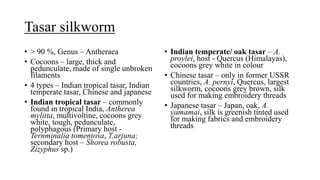

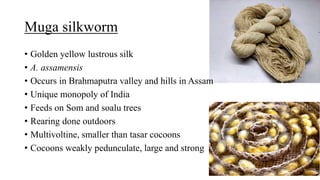

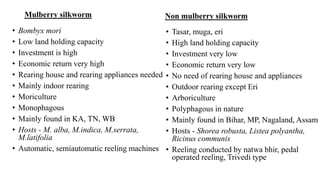

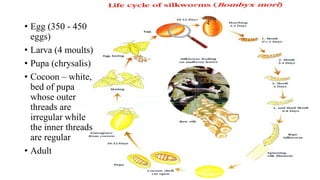

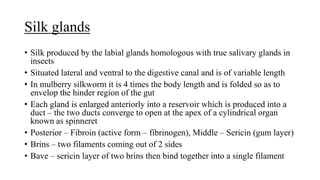

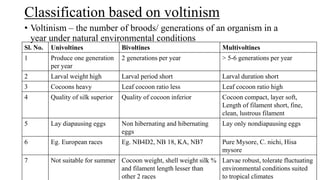

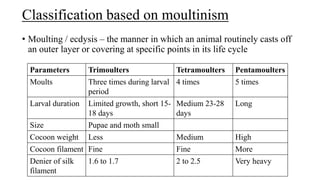

Sericulture is the large-scale cultivation of silk-producing organisms for silk extraction, which has a rich history dating back to 2687 BC. The document details the biology, types of silkworms, and the extensive uses of silk, from textiles to surgical threads, as well as the cultivation of mulberry trees for silkworm feed. It also provides insights into the economic aspects of sericulture, the rearing process, and the importance of selecting quality silkworm races.