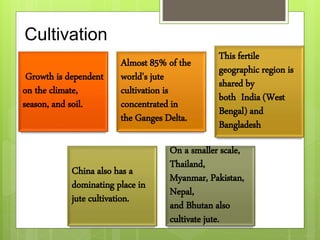

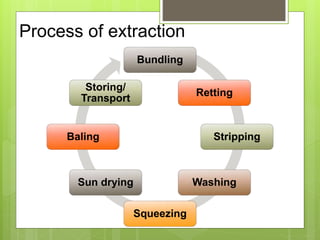

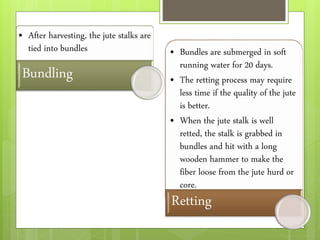

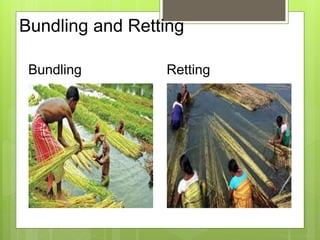

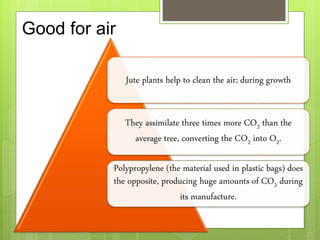

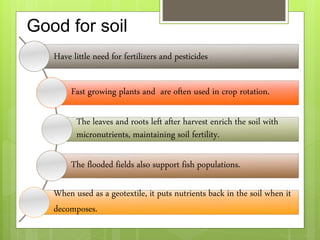

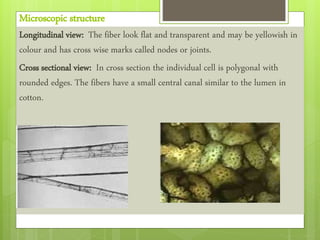

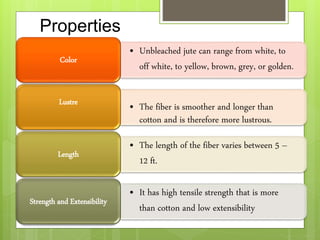

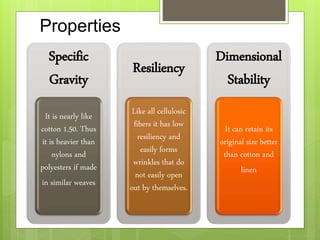

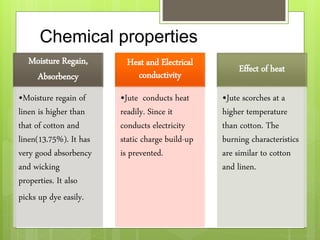

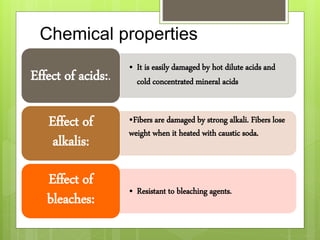

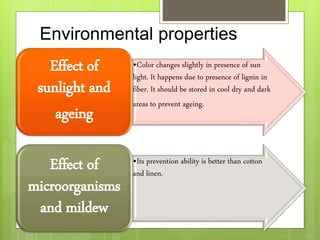

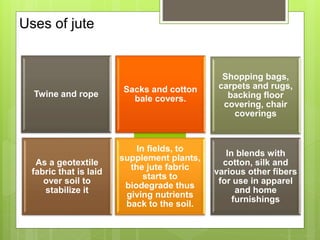

Jute is a bast fiber known as the 'golden fiber' due to its color and eco-friendliness, second in usage only to cotton. The cultivation process involves various stages from seeding to harvesting and extracting fibers, with jute being beneficial for air and soil health, requiring little to no pesticides or fertilizers. Its properties include high tensile strength, good absorbency, and diverse applications such as twine, bags, and geotextiles.