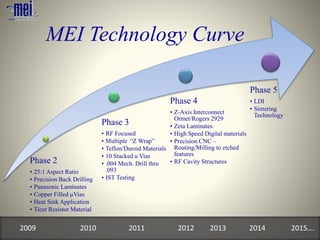

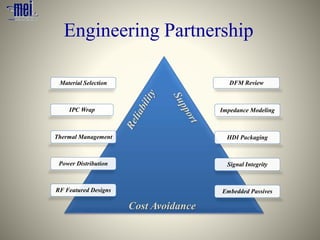

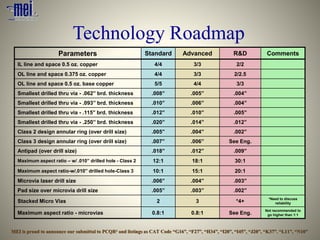

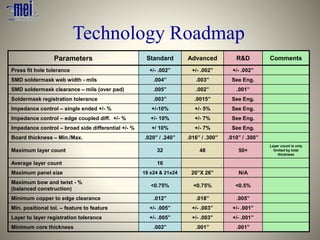

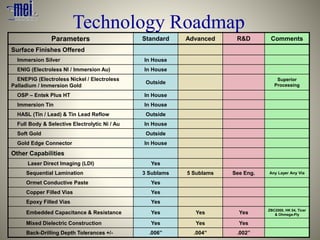

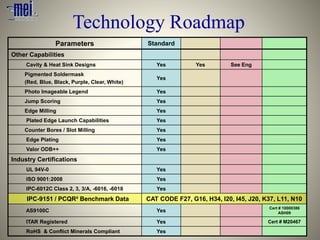

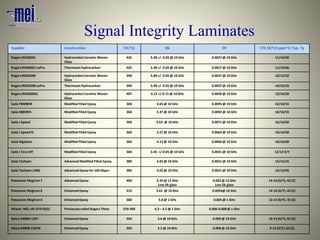

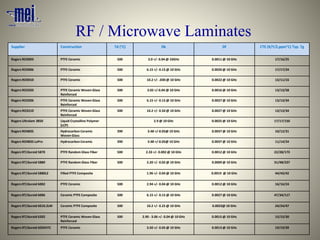

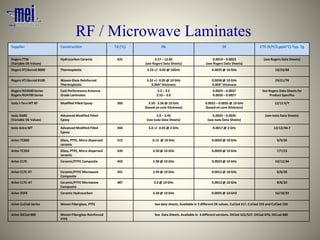

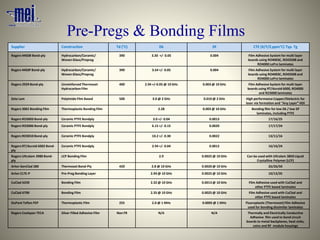

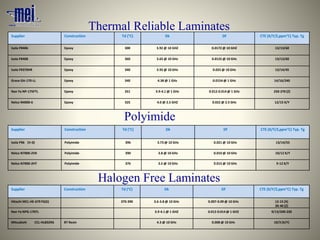

This document provides information about Marcel Electronics International (MEI), a privately owned electronics manufacturing company located in Orange, CA. It has been in business since 1979 and has 42,000 square feet of manufacturing space with 150 employees. MEI specializes in printed circuit board fabrication and assembly for the defense and aerospace industries as well as commercial sectors like wireless and medical. The document outlines MEI's certifications, technology capabilities, and the materials it supports for high frequency applications.