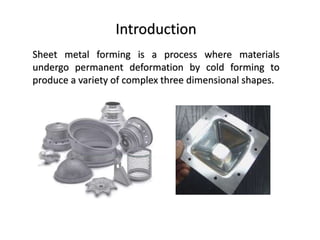

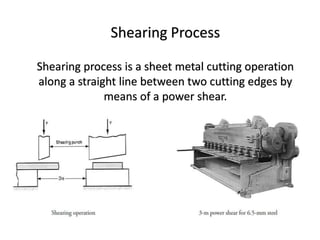

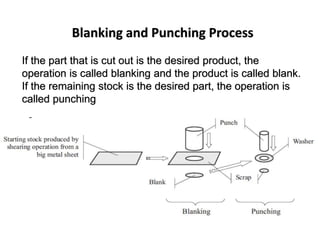

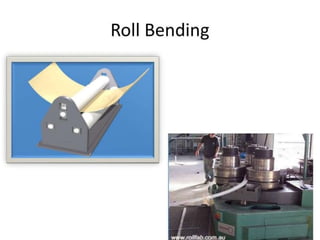

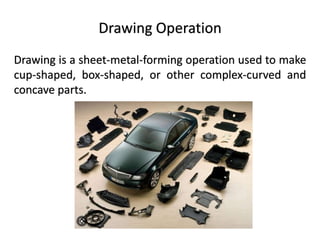

Sheet metal forming involves permanently deforming materials through cold forming processes to make complex 3D shapes. There are several types of sheet metal forming operations including cutting, bending, and drawing. Cutting separates sheets into pieces or makes holes using shearing, blanking, or punching processes. Bending transforms straight lengths into curves using a punch and die. Drawing is used to make cup-shaped or box-shaped parts by pressing sheet metal into a die opening with a punch.