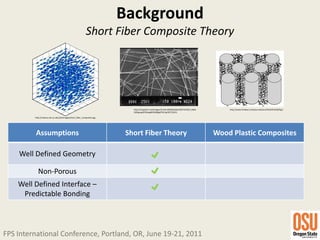

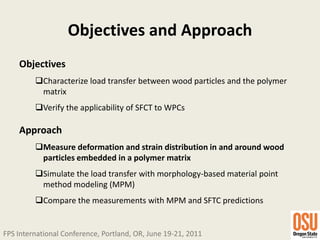

The document discusses techniques for measuring the tensile properties of individual wood flour particles embedded in a polymer matrix. Specifically, it examines applying short fiber composite theory to wood-plastic composites. The key points covered include:

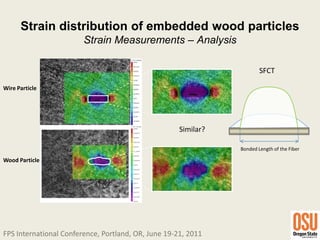

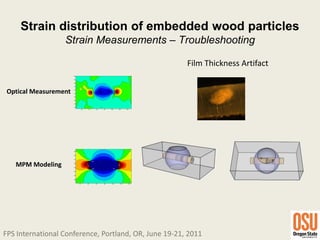

1) Preparing wood-plastic composite samples with wood flour particles and measuring their strain distribution using optical methods and modeling.

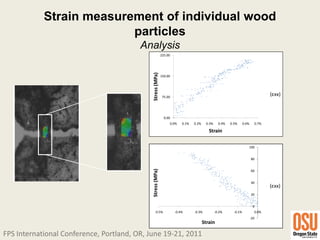

2) Comparing the strain measurements around embedded particles to predictions from short fiber composite theory and morphology-based material point modeling.

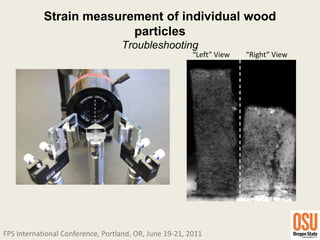

3) Troubleshooting challenges with the optical strain measurements, such as apparent negative strains, and exploring using 3D digital image correlation to directly measure strain on individual wood particles.