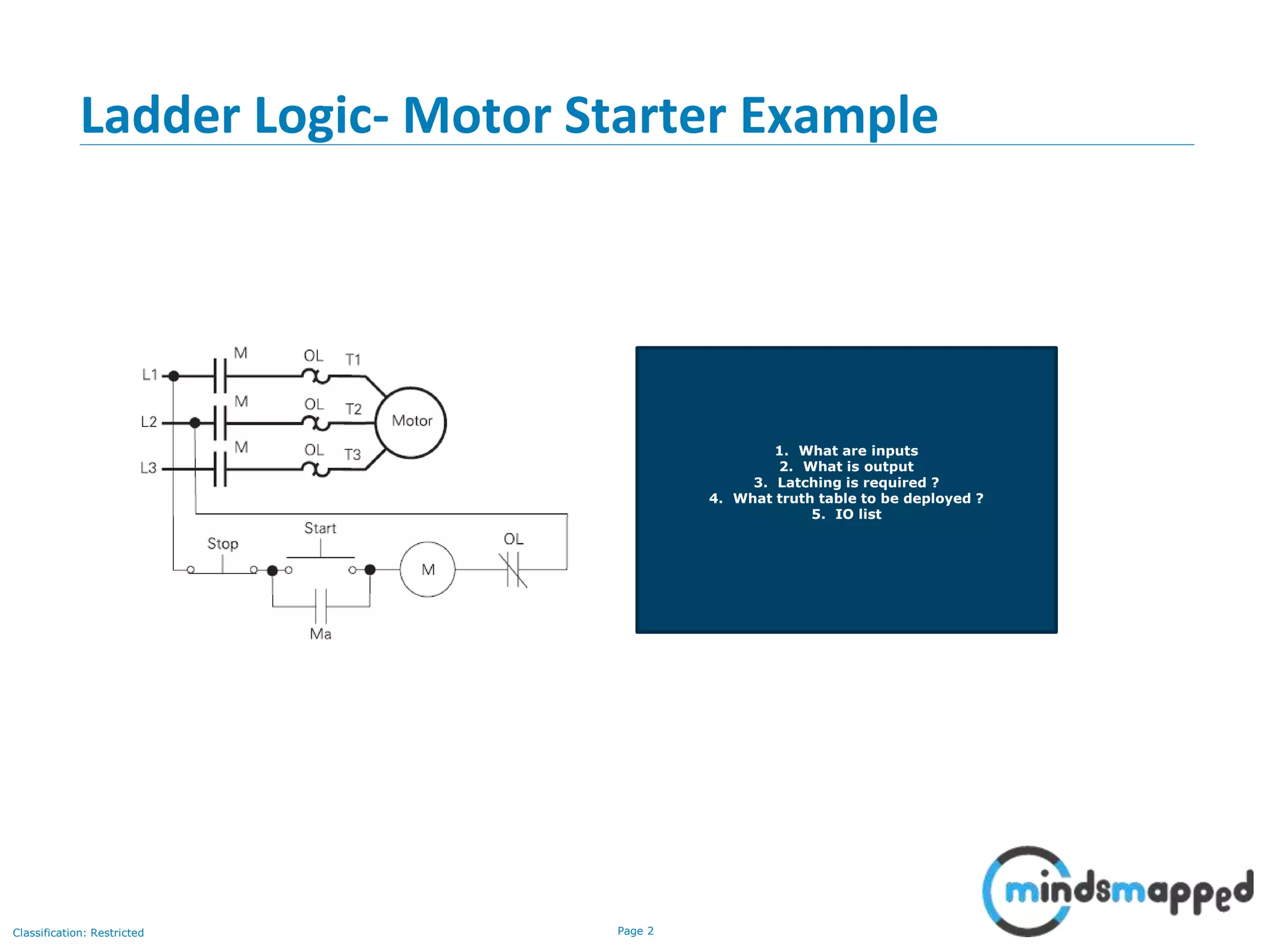

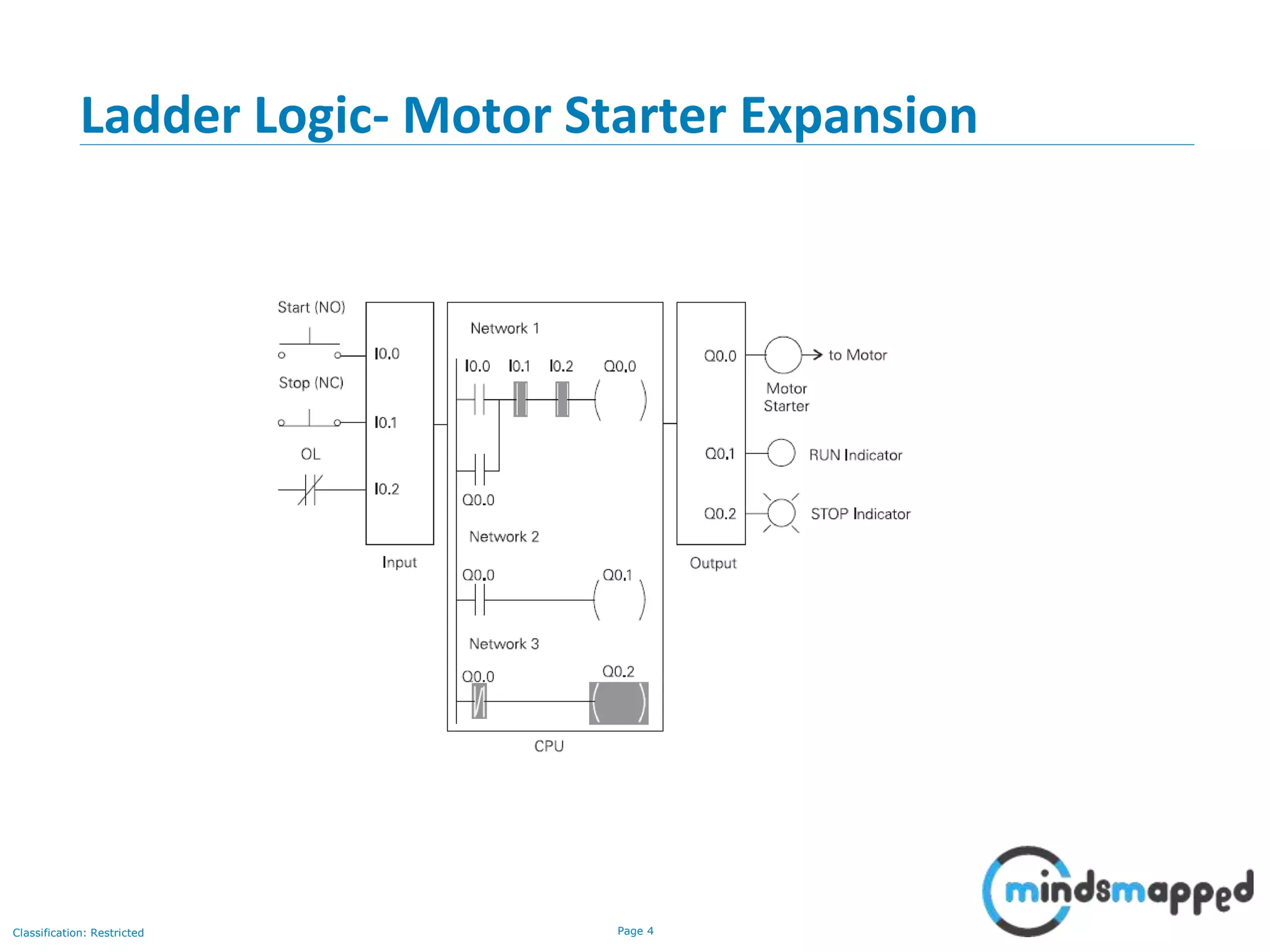

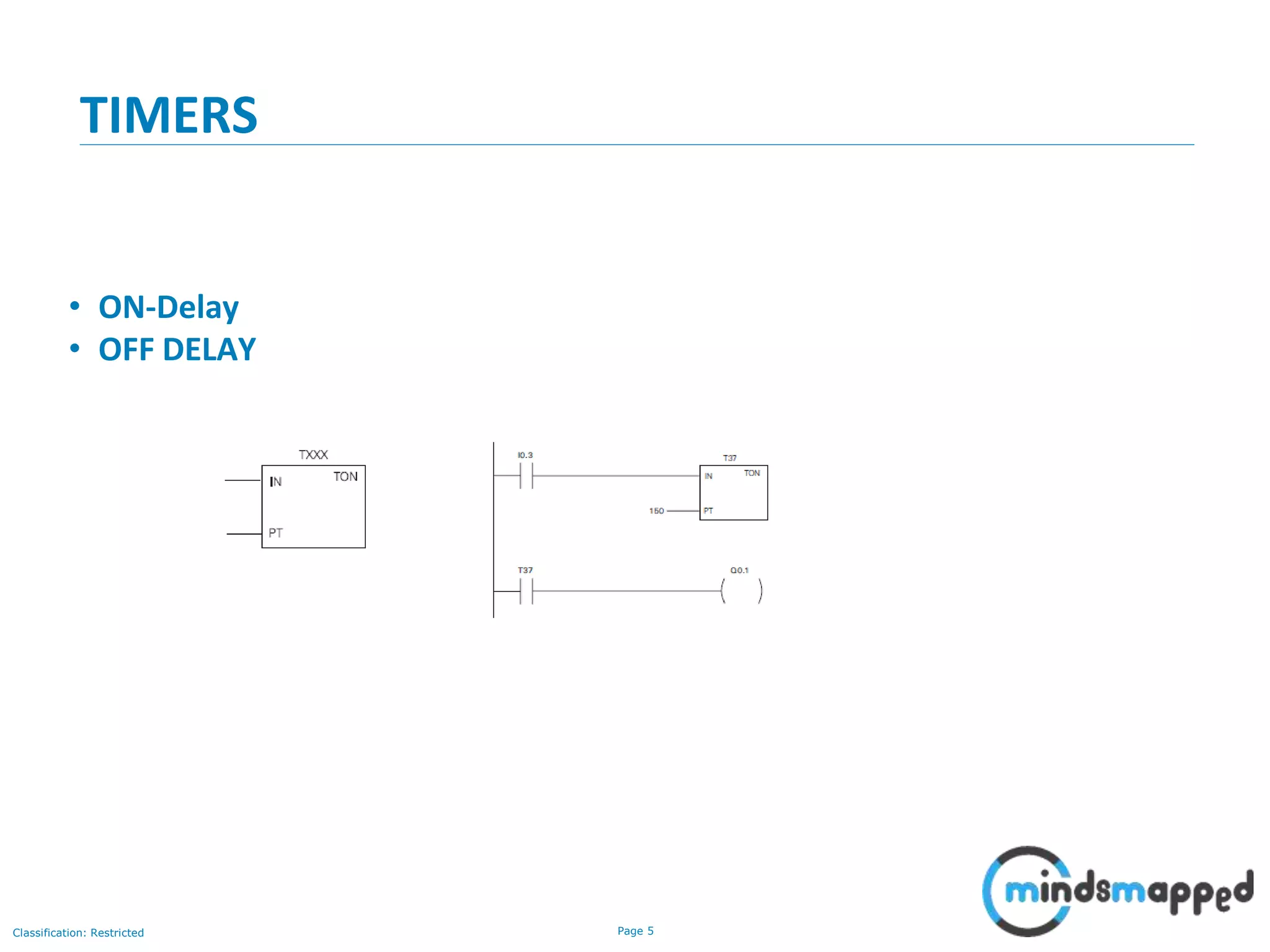

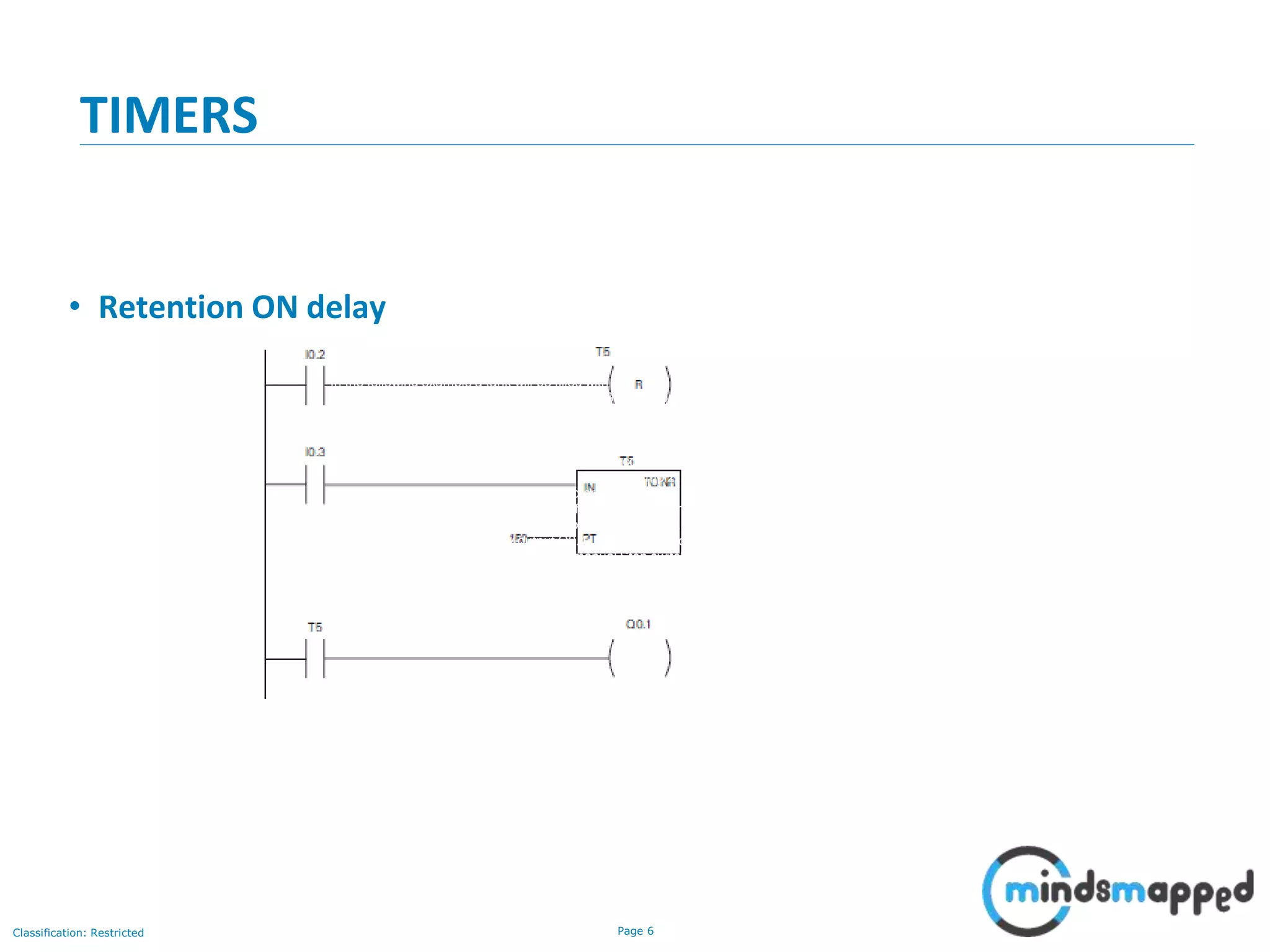

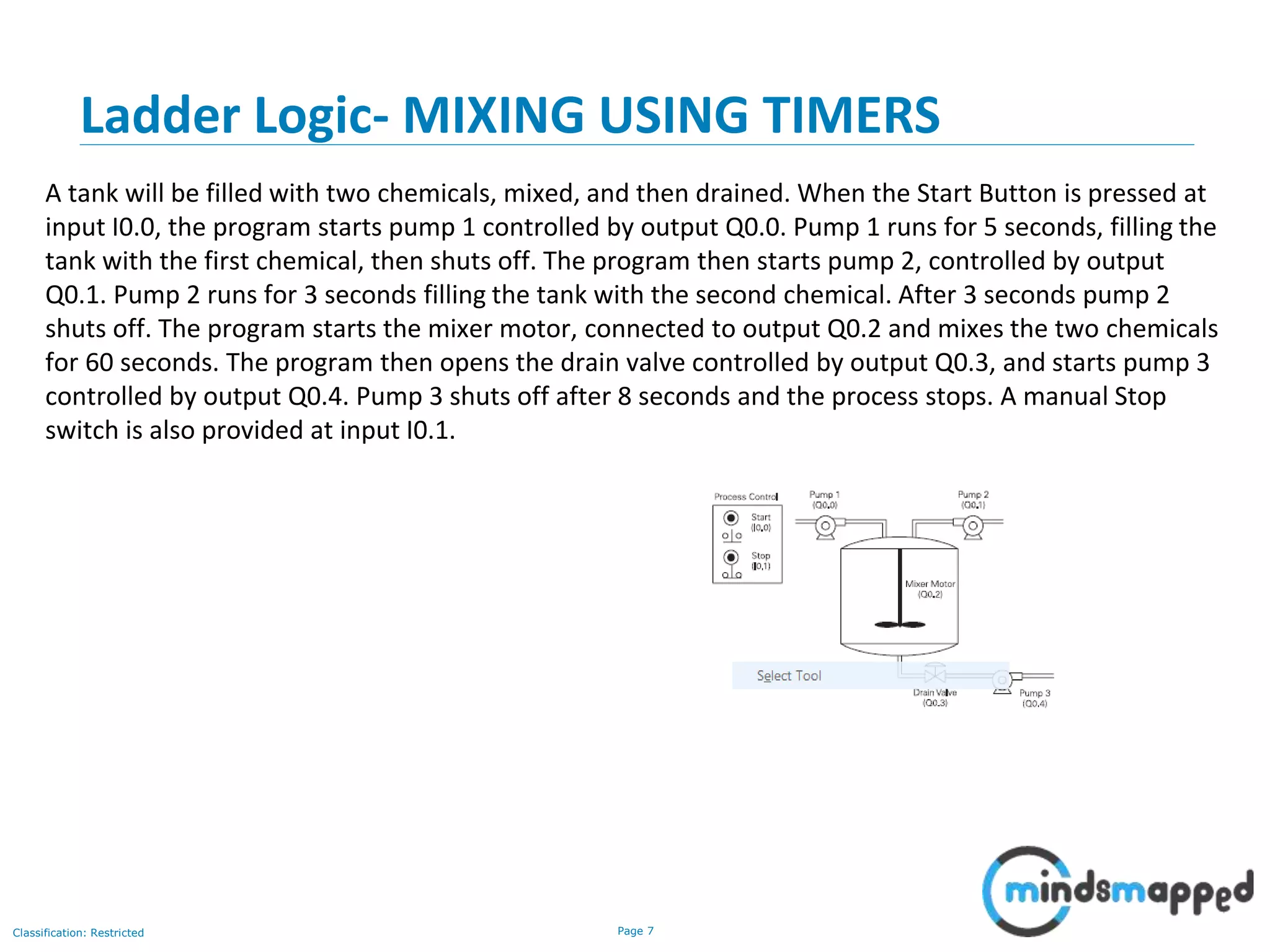

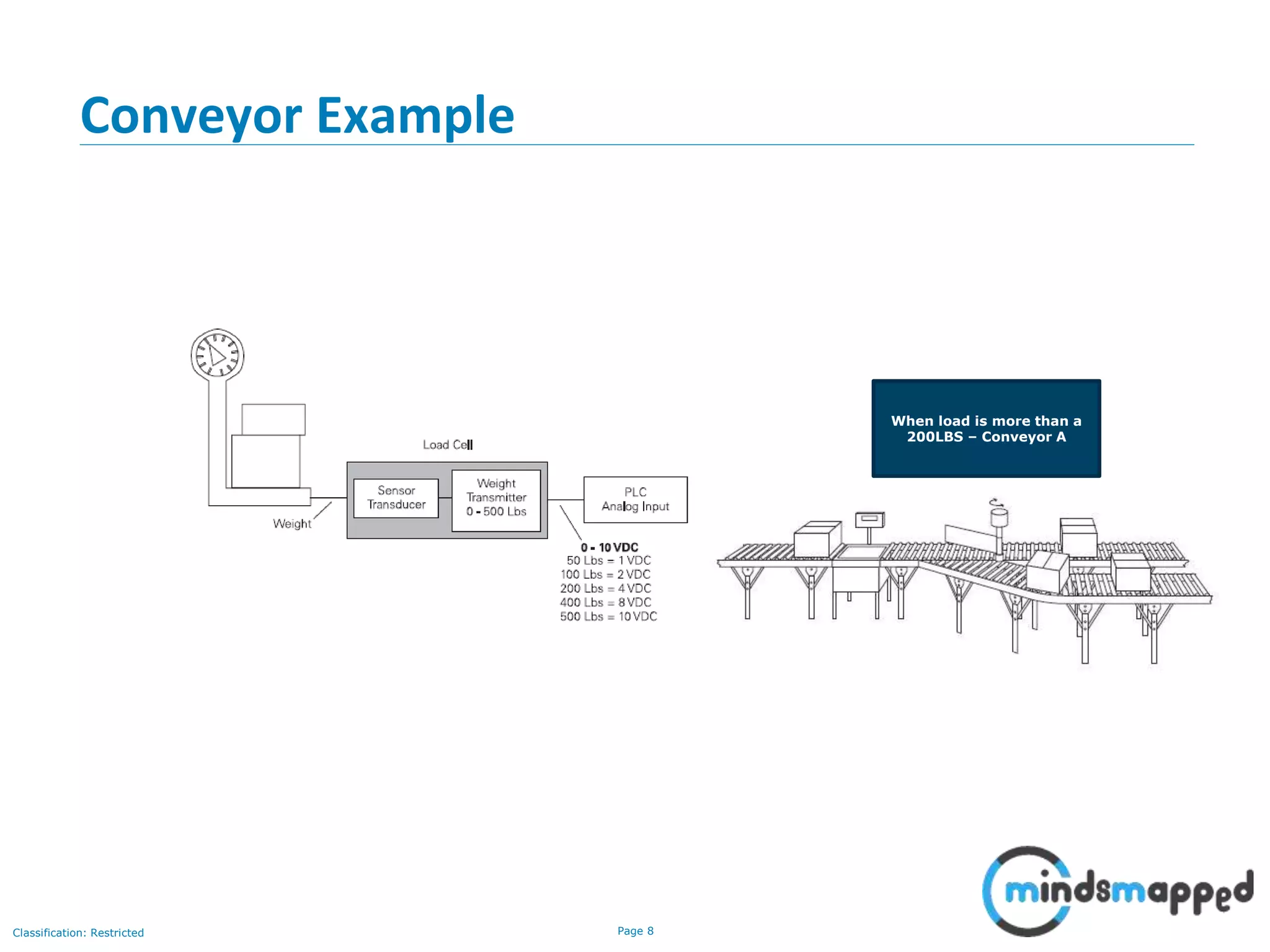

The document details an industrial automation training session focusing on ladder logic exercises, including examples of motor starters and timers. It describes a process where two chemicals are mixed and drained, controlled by various pumps and timers. The agenda also outlines upcoming topics for the next session, such as SCADA elements and technology implementation.