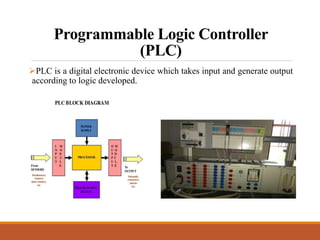

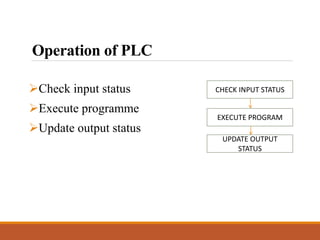

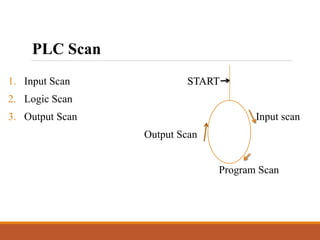

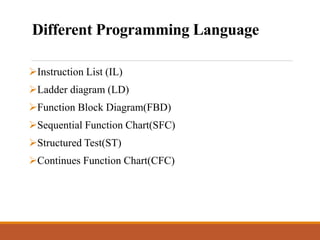

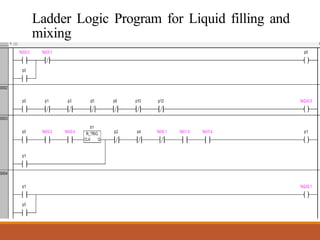

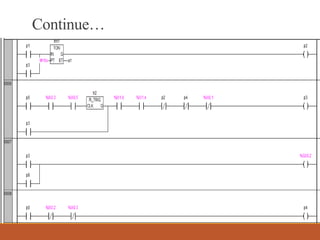

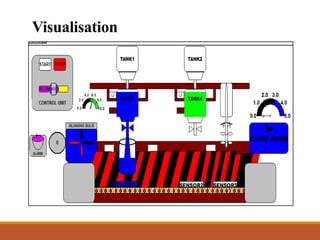

This document discusses a project on automation in liquid filling and mixing processes, focusing on the use of a Programmable Logic Controller (PLC) to enhance productivity and accuracy. It outlines the working of PLCs, different programming languages, hardware requirements, and advantages such as increased reliability and efficiency, while also noting disadvantages like high initial costs. The proposed system aims for high-speed production with minimized liquid wastage and the capability to mix varying proportions of liquids.

![LADDER LOGIC

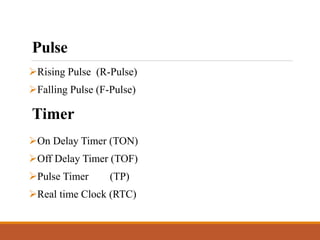

Ladder Logic has evolved into a programming language that represent

a program by graphical diagram.

—[ ]— Normally open contact

—[]— Normally closed

—( )— Normally inactive coil

—()— Normally active ("not") coil](https://image.slidesharecdn.com/majpro2017-190828131817/85/Automatic-liquid-filling-and-mixing-process-using-PLC-9-320.jpg)

![Reference

[1]. K. Kalaivani, V. Anjalipriya, P. Surendar, "Monitoring and control of

grain storage using PLC", Int. J. Res. Eng. Technol., vol. 1, no. 3, pp. 282-288,

2012.

[2]. S. Naik, J. Dias, J. D. Costa, J. Martin, B. D. Costa, "Optimized

preparations of chemical mixtures using PLC and SCADA", Int. J. Electr.

Electron. Res., vol. 3, no. 2, pp. 242-24 2015.

[3]. M. Trivedi, V. Sheoran, D. Tailor, "An analysis and control of a closed

loop conveyor system using PLC and sensors", Int. J. Innov. Emerg. Res. Eng.,

vol. 1, no. 1, pp. 1-6, 2014.

[4]. G. B. Shinde, V. P. Ghadage, A. A. Gadhave, D. K. Shedge, "PLC based

auto weighing control system", Int. J. Eng. Tech. Res., vol. 3, no. 3, pp. 213-

216, 2015.

[5]. P. Dheeraj, S. R. Suralkar, "Automatic multivariate liquid filling system

and conveyor control using PLC and SCADA", Int. J. Emerg. Technol. Adv.

Eng., vol. 4, no. 12, pp. 362-365, 2014.](https://image.slidesharecdn.com/majpro2017-190828131817/85/Automatic-liquid-filling-and-mixing-process-using-PLC-28-320.jpg)