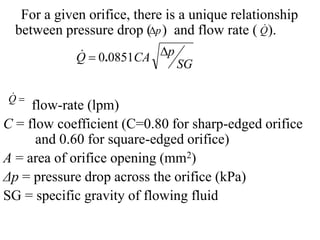

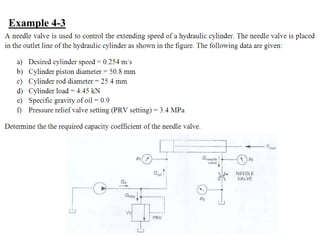

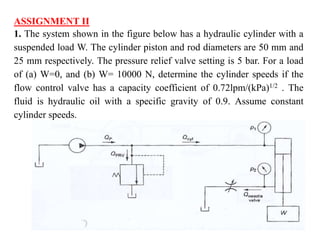

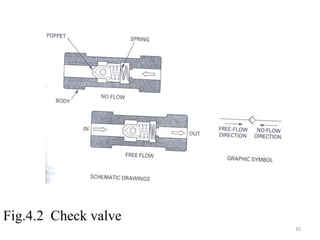

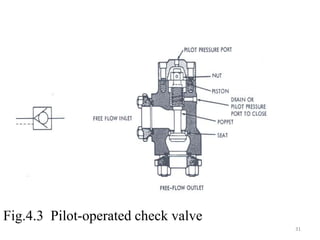

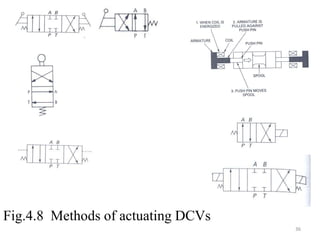

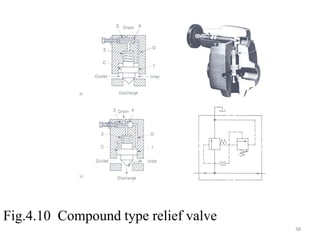

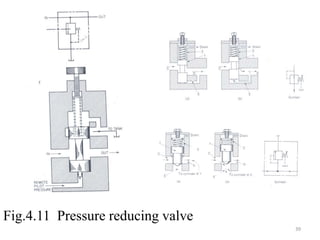

This document discusses different types of valves used in fluid power systems including directional control valves, pressure control valves, and flow control valves. It describes common valve types such as check valves, pilot-operated check valves, 3-way valves, 4-way valves, relief valves, pressure reducing valves, counterbalance valves, orifice flow control valves, and needle valves. Examples are also provided to illustrate how to calculate cylinder speed using a flow control valve and flow rate using an orifice plate.