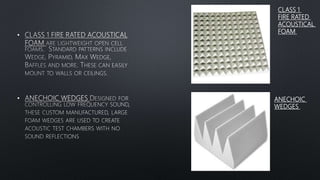

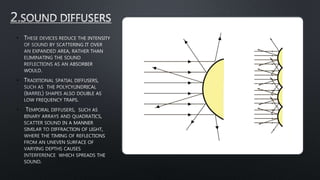

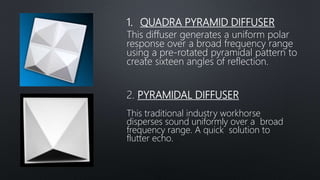

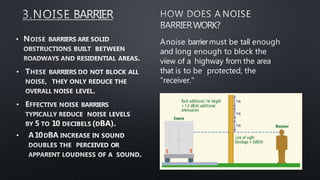

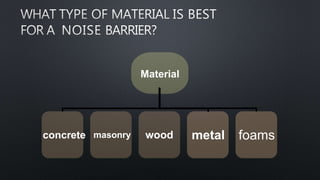

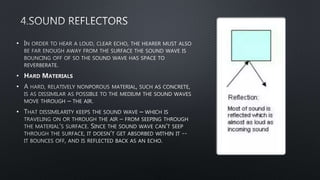

This document discusses various acoustic materials used for sound absorption, diffusion, and noise control. It provides details on stackable foam panels, fabric wrapped panels, ceiling clouds, fiberglass blankets and rolls, pyramidal and quadratic diffusers, and acoustic barriers. The materials discussed are suitable for a variety of spaces including recording studios, theaters, offices, homes and more. They help reduce reverberation, echoes, and noise in an aesthetically pleasing way while also being durable and fire resistant.