This document provides an overview of the building services systems at the Malaysia International Trade and Exhibition Centre (MITEC). It includes 3 sections that summarize the key fire protection, air conditioning, and mechanical transportation systems. The fire protection system utilizes sprinklers, hydrants, detectors, and alarms to help control fires. The air conditioning system includes chillers, cooling towers, air handling units, and fan coil units to provide temperature control. The mechanical transportation section describes the escalators and elevators that facilitate vertical transportation within the building.

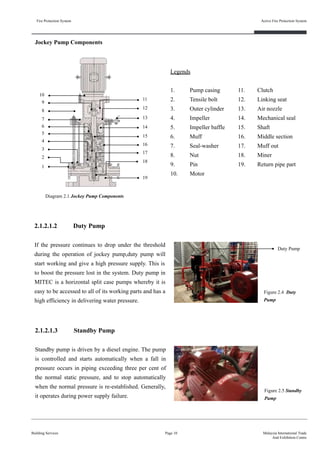

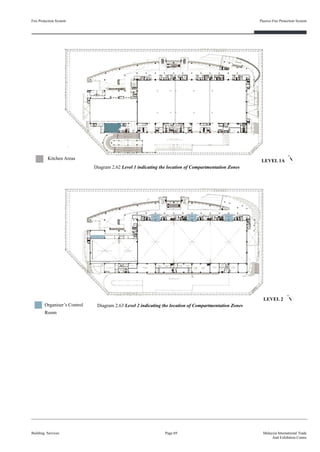

![2.1.2.1.1 Jockey Pump

Jockey pump, also known as a pressure-maintenance pump, is a

relatively small device that works together with the fire pump. It

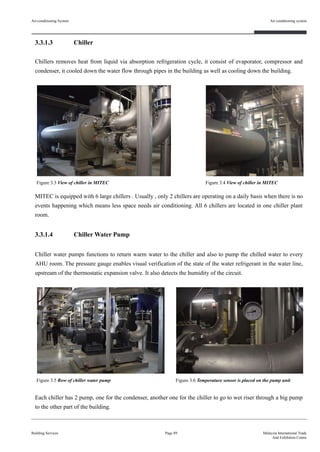

is designed to keep the pressure in the system elevated to a

specific level when the system is not in use, so that the fire pump

doesn’t have to run all the time. This prevents the sprinklers

from going off unnecessarily. Moreover, since pipes are

susceptible to leakage over time, the water pressure inside them

tends to go down. As soon as the jockey pump senses this, it fills

them back up to normal pressure. Also, it can also help prevent

the system from damage when a fire happens and pressurized

water rushes into the pipes by regulating the pressure. It is

powered by electric supply and is connected directly to the fire

sprinkler water tank.

Fire Protection System

Building Services

Active Fire Protection System

Page 9 Malaysia International Trade

And Exhibition Centre

Jockey Pump

Duty Pump

Standby Pump

Common Suction

Pipe

Common

Discharge Pipe

Figure 2.1 An overview of fire pump system and sprinkler tank

Figure 2.3 EBSRAY Jockey Pump

Figure 2.2 Fire sprinkler tank and wet

riser-hose reel tank

UBBL 1984

Part VIII: Fire Alarms, Fire Detection, Fire Extinguishment and Fire Fighting Access

[ Clause 247 ] Water Storage

(1) Water storage capacity and water flow rate for fire fighting systems and installations shall be

provided in accordance with the scale as set out in the Tenth Schedule to these By-laws.

(2) Main water storage tanks within the building, other than for hose reel systems, shall be

located at ground, first or second basement levels, with fire brigade pumping inlet

connections accessible to fire appliances.

(Uniform Building By-Law, 2006, pp. 87) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-22-320.jpg)

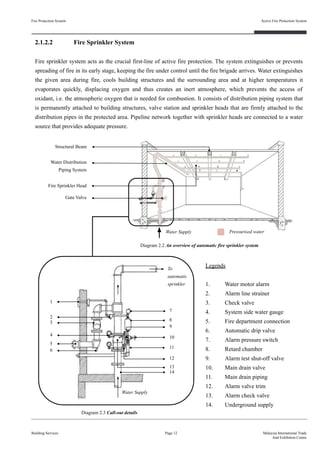

![Fire Protection System

Building Services

Active Fire Protection System

Page 11 Malaysia International Trade

And Exhibition Centre

2.1.2.1.4 Pumpset Pressure Indicator

Standby pump is driven by a diesel engine. The pump

is controlled and starts automatically when a fall in

pressure occurs in piping exceeding three per cent of

the normal static pressure, and to stop automatically

when the normal pressure is re-established. Generally,

it operates during power supply failure.

Figure 2.6 Pumpset

Pressure Indicator

2.1.2.1.5 Fire Pump Controller

The fire pump controller is designed to monitor the

operation status and in the case of fire, the controller

will receive a signal from the pressure switch and start

the fire pump. The fire switch in the controller is

passive, requiring no manual operation by the owner.

Water pressure does it all. When the pressure drops,

the normally open contacts close, completing the

electrical circuit and activating the pump.

Figure 2.7 Fire

Pump Controller

UBBL 1984

Part VIII: Fire Alarms, Fire Detection, Fire Extinguishment and Fire Fighting Access

[ Clause 226 ] Automatic System for Hazardous Occupancy

Where hazardous processes, storage or occupancy are of such character as to require automatic

sprinklers or other automatic extinguish fires in the hazardous materials stored or handled or for the

safety of the occupants.

Summary (Fire Pump) :

The water storage tank for both wet riser system and fire sprinkler system meets the UBBL 1984 requirement

listed under Clause 247, (2). The tanks are located on the fire appliance access level for the ease of monitoring.

The automated system including fire pump system, fire sprinkler system and water cannon system meets the

UBBL 1984 requirement listed under Clause 226.

(Uniform Building By-Law, 2006, pp. 82) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-24-320.jpg)

![Fire Protection System

Building Services

Active Fire Protection System

Page 16 Malaysia International Trade

And Exhibition Centre

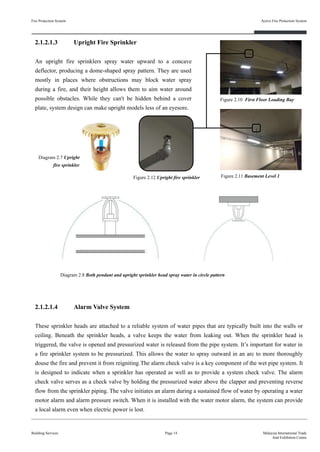

UBBL 1984

Part VIII: Fire Alarms, Fire Detection, Fire Extinguishment and Fire Fighting Access

[ Clause 228 ] Sprinkler Valves

(1) Sprinkler valves shall be located in a safe and enclosed position on the exterior wall and

shall be readily accessible to the Fire Authority

(2) All sprinkler system shall be electricity connected to the nearest fire station to provide

immediate and automatic relay of the alarm when activated.

Summary (Fire Sprinkler System) :

The fire sprinkler system in MITEC meets the UBBL 1984 requirements listed under clause 228, (1) and (2). In

Figure 2.13, the sprinkler alarm valve system is placed along the exterior wall of the fire pump room located at

ground floor. This allow ease of monitoring during the event of fire even without access into the fire pump room.

Also, it is connected to the fire alarm system which is directly linked to the nearest fire station through the fire

control panel.

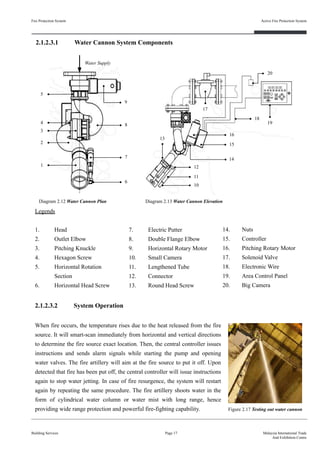

2.1.2.3 Water Cannon System

There are 12 water cannons located at level 3 in the largest exhibition

pillar-less hall. The water cannon system employed in MITEC is an

automatic tracking technology with mechanized positioning fire

artillery, combining the infrared sensor technology. The signal

processing technology, communication control technology, computer

technology and mechanical driven technology work together effectively.

It is exceptionally suitable for tall and big space like the pillar-less hall. Figure 2.16 Water Cannon System

Diagram 2.11 Location of Pillar-less Exhibition Hall where the water cannon system is located

(Uniform Building By-Law, 2006, pp. 82) (Original work published in 1984)

SECTION B-B’](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-29-320.jpg)

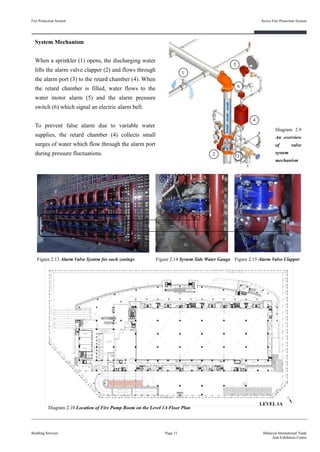

![Fire Protection System

Building Services

Active Fire Protection System

Page 18 Malaysia International Trade

And Exhibition Centre

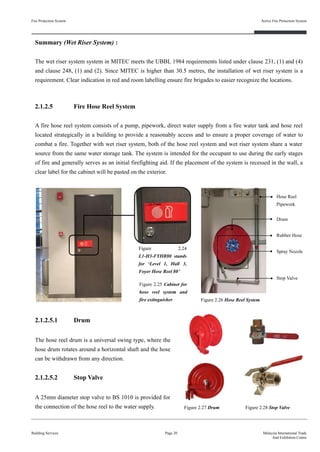

2.1.2.4 Wet Riser System

MITEC has a height of 63 metres above the fire appliance access level therefore wet riser system is installed to

supply pressurized water within buildings for firefighting purposes. The wet rise system in MITEC consists of a

wet riser main, a wet riser landing valve and a hose cradle. Some of the system are being recessed in the wall

located in a cabinet clearly labelled ‘Sesalur Basah’ on a red panel, which means ‘wet riser’ when being direct

translated into English language.

UBBL 1984

Part VIII: Fire Alarms, Fire Detection, Fire Extinguishment and Fire Fighting Access

[ Clause 231 ] Installation and testing of wet rising system

(1) Wet rising systems shall be provided in every building in which the topmost floor is more

than 30.5 metres above fire appliance access level.

[ Clause 248 ] Markings on wet riser, etc.

(1) Wet riser, dry riser, sprinkler and other fire installation pipes and fittings shall be painted

red.

(2) All cabinets and areas recessed in walls for location of fire installations and extinguishers

shall be clearly identified to the satisfaction of the Fire Authority or otherwise clearly

identified.

Figure 2.18 Wet Riser System

Wet Riser

Main

Wet Riser

Landing Valve

Canvas Hose

Hose Cradle

Figure 2.19 Wet riser system that located in the wall

(Uniform Building By-Law, 2006, pp. 84, 87) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-31-320.jpg)

![Fire Protection System

Building Services

Active Fire Protection System

Page 19 Malaysia International Trade

And Exhibition Centre

2.1.2.4.2 Wet Riser Landing Valve

Landing valves which are 65mm in diameter, connecting directly to

the wet riser main, serve as the main water supply to fire department

to the upper floors in MITEC whereas fire hydrants serve as the

water source on the ground level. It functions as a water tab whereby

it is to connect the canvas hose to access to the water source on the

upper levels for fire-fighting. The valves are equipped with a

coupling adapter which is directly screwed to the outlet and

stoppered with a cap.

2.1.2.4.1 Wet Riser Main and Air Vent

Wet fire mains are 150mm in diameter and are installed owing to the

pressures required to provide adequate fire-fighting water supplies at

the landing valves at upper floors and also to ensure that water is

immediately available at all floor levels. The provision of a built-in

water distribution system means that firefighters do not need to

create their own distribution system in order to fight a fire and

avoids the breaching of fire compartments by running hose lines

between them.

2.1.2.4.3 Canvas Hose and Hose Cradle

Hose Cradle and Canvas Hose of brand ‘Proflex’ is used in MITEC.

The canvas hose has a length of 30 metres and 65mm in diameter. It

is connected to a faucet and placed on a hose cradle nearby the

landing valve. The hose has no all-time water supply like hose reel

system.

Figure 2.20 Wet riser main

Outlet Coupling Adapter

Figure 2.22 Landing Valves on the top floor

UBBL 1984

Part VIII: Fire Alarms, Fire Detection, Fire Extinguishment and Fire Fighting Access

[ Clause 231 ] Installation and testing of wet rising system

(4) Each wet risers outlet shall comprise standard 63.5 millimeters instantaneous coupling fitted

with a hose of not less than 38.1 millimeters diameter equipped with an approved typed

cradle and a variable fog nozzle.

Figure 2.23 Canvas hose placed on the cradle

Figure 2.21 Air Vent

(Uniform Building By-Law, 2006, pp. 84) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-32-320.jpg)

![Fire Protection System

Building Services

Active Fire Protection System

Page 21 Malaysia International Trade

And Exhibition Centre

2.1.2.5.5 System Operation

The system is manually operated and activated by opening the stop valve, enabling the water to flow into the

hose that is 30 meters long. The system pressure loss will activate the pump, ensuring adequate water flow and

pressure to provide a water jet of a minimum of 10 meter from the nozzle (0.33L of water per second). The

nozzle attached to the hose enables the operator to control the direction and flow of water to the fire.

Turn water on to the hose reel

by operating the control valve

and remove the nozzle from its

bracket.

Direct the water at the base of

the flames and extinguish the

fire by using a sweeping

action.

Proceed to a safe distance

from the fire and turn the

water on by operating the

nozzle.

UBBL 1984

Part VIII: Fire Alarms, Fire Detection, Fire Extinguishment and Fire Fighting Access

[ Clause 231 ] Installation and testing of wet rising system

(2) A hose connection shall be provided in each fire fighting access lobby

2.1.2.5.3 Spray Nozzle

The shut-off nozzle assembly which is fitted at the end

of the hose is constructed of corrosion resistant material.

There are markings to indicate the open/shut positions of

the nozzle.

2.1.2.5.4 Rubber Hose

The fire hose reel is made of non-kinking, braided

rubber type and the length of the hose is 30 meter. Figure 2.30 Spray NozzleFigure 2.29 Rubber Hose

(Uniform Building By-Law, 2006, pp. 84) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-34-320.jpg)

![Fire Protection System

Building Services

Active Fire Protection System

Page 22 Malaysia International Trade

And Exhibition Centre

2.1.2.6 Dry Riser System

Dry riser system is empty and is only filled with water by fire fighters when they arrive. Fire fighters will

connect the pump outlet in one of their appliances to the dry riser inlet located at fire appliance access level. The

system in MITEC consists of an empty pipe of a diameter of 150mm running up the inside of a building which

can be connected to by firefighters. Water is then drawn from the nearest public fire hydrant and this is

pressurised by the fire pump to provide water at the correct flow and pressure for fire fighting operations at the

relevant upper floor level.

Summary (Fire Hose Reel System) :

The fire hose reel system in MITEC meets the UBBL 1984 requirements listed under clause 231, (2). Each fire

lobbies is provided with the system, clearly indicated with numbering system.

UBBL 1984

Part VIII: Fire Alarms, Fire Detection, Fire Extinguishment and Fire Fighting Access

[ Clause 230 ] Installation and testing of dry rising system

(1) Dry rising systems shall be provided in every building in which the topmost floor is more

than 18.3 metres but less than 30.5 metres above fire appliance access level.

Figure 2.32

Dry Riser

Inlet

Figure 2.31

Dry Riser

Outlet

Air Vent

External Wall

Summary (Dry Riser System) :

The dry riser system in MITEC meets the UBBL 1984 requirements listed under clause 230, (1) whereby

MITEC is provided with the system since it is more than 18.3 metres from the fire appliance access level

(Uniform Building By-Law, 2006, pp. 83) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-35-320.jpg)

![Fire Protection System

Building Services

Active Fire Protection System

Page 23 Malaysia International Trade

And Exhibition Centre

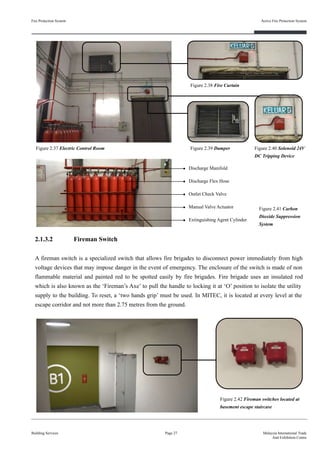

2.1.2.7 Fire Hydrant System

A fire hydrant system is a water supply with a sufficient

pressure and flow delivered through pipes throughout a

building to strategically located network of valves for

fire-fighting purposes. Two way fire hydrant installation

in MITEC consists of a system of pipe work connected

directly to the water supply main to provide water to each

and every hydrant outlet and is intended to provide water

for the firemen to fight a fire. Where the water supply is

not reliable or inadequate, hydrant pumps are provided to

pressurize the fire mains. A firefighter connects a fire hose

to the fire hydrant and releases a valve to get water from

the water main. The fire hydrants are designed to allow

250 gallons of water to flow through the hydrant per

minute.

Body Material : Cast Iron to BS 1452

Outlet : Copper alloy BS 1400

Test Pressure : 30 bar (435 Psi)

Working Pressure : 20 bar (290 Psi)

Finishing : Yellow painting

Private hydrant

Figure 2.33 Fire Hydrant located at staff car park

UBBL 1984

Part VIII: Fire Alarms, Fire Detection, Fire Extinguishment and Fire Fighting Access

[ Section 225 ] Detecting and extinguishing fire

(3) Depending on the size and location of the building and the provision of access for

appliances, additional fire hydrant shall be provided as may be required by the Fire

Authority.

Summary (Fire Hydrant System) :

The external fire hydrant system in MITEC meets the UBBL 1984 requirements listed under Section 225, (3)

whereby they are placed around the perimeter of the building to provide immediate access for the fire brigades

during the event of fire.

(Uniform Building By-Law, 2006, pp. 82) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-36-320.jpg)

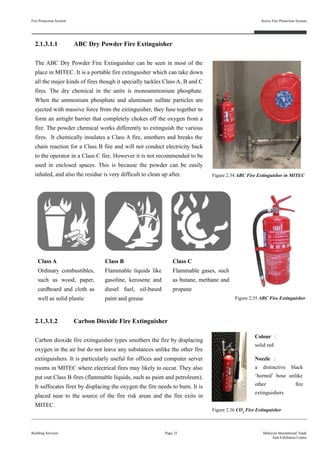

![2.1.3.1.3 Carbon Dioxide Suppression System

Carbon dioxide (CO2) is a colorless, odorless, and chemically inert gas that is both readily available and

electrically non-conductive that leaves no residue behind. This means any sensitive equipment that is in the

protected space is not damaged by the CO2, which reduces downtime and costs. Once the CO2 has dispersed to

safe levels from the protected space, personnel can access any damage from the fire or smoke and quickly get

back to work with no cleanup needed. It extinguishes fire primarily by lowering the level of oxygen that supports

combustion. This mechanism of fire suppression is highly effective, requiring minimal clean-up and is used in

normally unoccupied hazard locations or otherwise avoided by personnel when discharged. In MITEC, each

electrical room has an carbon dioxide suppression system.

Fire Protection System

Building Services

Active Fire Protection System

Page 26 Malaysia International Trade

And Exhibition Centre

Diagram 2.14 System Operation Overview

UBBL 1984

Part VIII: Fire Alarms, Fire Detection, Fire Extinguishment and Fire Fighting Access

[ Section 227 ] Portable Extinguishers

Portable extinguisher shall be provided in accordance with the relevant codes of practice and shall

be sited in prominent positions on exit routes to be visible from all directions and similar

extinguishers in a building shall be of the same method of operation.

Summary (Fire Extinguisher) :

The fire extinguishers system in MITEC meets the UBBL 1984 requirements listed under Section 227, (3). The

fire extinguishers are strategically placed at many locations to be easily accessible by users in the building

during the event of fire.

System Operation

A carbon dioxide fire suppression system eliminates the oxygen to

suppress the fire. The system is equipped with a smoke and heat

detector which will trigger the alarm system and send signal to the fire

control room through the fire control panel upon detecting smoke and

temperature rise. It then releases the carbon dioxide agent into the space

it is protecting. After 30 seconds, all the gas inside will be discharged

through piping, leaving only carbon dioxide inside with the fire curtain

opened and smoke damper closed. The drop in oxygen level quickly

causes the fire to be suppressed or extinguished. On the control panel

outside, if green light lights up, it means that personnel is free to enter

the room whereas if the red light lights up, it means that the carbon

dioxide agent is being discharged and the room cannot be entered.

Extinguishing

Agent

Control

Panel

Detector

Nozzle

(Uniform Building By-Law, 2006, pp. 82) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-39-320.jpg)

![Fire Protection System

Building Services

Active Fire Protection System

Page 28 Malaysia International Trade

And Exhibition Centre

2.1.3.3 Voice Communication System

It is a two-way emergency communication system

connecting fireman intercoms located throughout the

building and a master telephone handset is located in the

fire control room. The fireman intercom handset is being

placed behind a locked door, housed within a red metal

cabinet and rested on a cradle. Lifting the handset from the

cradle will cause the buzzer to sound and light a ‘common

call’ indicator. A maximum call of 7 RFIS and master

handsets can communicate simultaneously.

Figure 2.43 Fireman Intercom located at basement escape

staircase (left) and fire pump room

UBBL 1984

Part VIII: Fire Alarms, Fire Detection, Fire Extinguishment and Fire Fighting Access

[ Section 239 ] Voice Communication System

There shall be two separate approved continuously electrically supervised voice communications

systems, one a fire brigade communications system and the other a public address system between

the central control station and the following areas :

(a) Lifts, lift lobbies, corridors and staircases;

(b) In every office area exceeding 92.9 square metres in area;

(c) In each dwelling unit and hotel guest room where the fire brigade system may be combined

with the public address system.

Summary (Voice Communication System) :

The voice communication system in MITEC meets the UBBL 1984 requirements listed under Section 239. The

two-way communication system ensures the connection between the master handset in the fire control room and

the remote fireman corridor. This allows efficient communication in the event of fire or emergency.

2.1.3.4 Emergency Speaker

The emergency speaker is a network of monitored loud speakers.

The speakers are distributed throughout MITEC to ensure warning

messages and tones satisfy a specific sound pressure level

(volume) and are distinctly audible throughout all required areas

of the building. Also, it ensures warning messages are intelligible

and clearly understood by the occupants.

Figure 2.44

Emergency

Speaker

(Uniform Building By-Law, 2006, pp. 85) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-41-320.jpg)

![Fire Protection System

Building Services

Active Fire Protection System

Page 29 Malaysia International Trade

And Exhibition Centre

2.1.3.5 Emergency Light

An emergency light is a battery-backed lighting device that

switches on automatically when a building experiences a

power outage. During an event of emergency, it is used to

illuminate the access pathways leading to the exits, fire

staircase, aisles, corridors, ramps and at the exit discharge

pathways towards public area. The level of illumination and

quality consistency of emergency illumination are the crucial

factors to the safety occupants during evacuation.

UBBL 1984

Part VIII: Fire Alarms, Fire Detection, Fire Extinguishment and Fire Fighting Access

[ Section 253 ] Emergency power system

(1) Emergency power system shall be provided to supply illumination and power automatically

in the vent of failure of the normal supply or in the event of accident to elements of the

system supplying power and illumination essential for safety of life and property.

(5) Current supply shall be such that in the event of failure of the normal supply to or within the

buildings concerned, the emergency lighting or emergency power, or both emergency

lighting and power will be available within 10 seconds of the interruption of the normal

supply. The supply system for emergency purposes shall comprise one of the following

approved types:

(a) Storage Battery

Storage Battery of suitable rating and capacity to supply and maintain at not less

than 871/2 percent of the system voltage the total of the circuits supplying

emergency lighting and emergency power for a period of at least 11/2 hours;

(b) Generator set

A generator set driven by some form of prime mover and of sufficient capacity and

proper rating to supply circuit carrying emergency lighting or lighting and power

with suitable means for automatically starting the prime mover on failure on the

normal service.

Summary (Emergency Light) :

The emergency light system in MITEC meets the UBBL 1984 requirements listed under Section 253, (1) and (5).

The emergency lights are well-maintained and equipped with storage battery to ensure proper lighting during the

event of emergency.

Figure 2.45 Emergency light

(Uniform Building By-Law, 2006, pp. 88) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-42-320.jpg)

![Fire Protection System

Building Services

Active Fire Protection System

Page 33 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part VII: Fire Requirements

[ Section 153 ] Smoke detectors for lift lobbies

(1) All life lobbies shall be provided with smoke detectors.

(2) Lift not opening into a smoke lobby shall not use door reopening devices controlled by light

beam or photodetectors unless incorporated with a force close feature which after thirty

seconds of any interruption of the beam cause the door to close within a preset time.

Part VIII: Fire Alarms, Fire Detection, Fire Extinguishment and Fire Fighting Access

[ Section 225 ] Detecting and extinguishing fire

(1) Every building shall be provided with means of detecting and extinguishing fire and with

fire alarms together with illuminated exit signs in accordance with the requirements as

specified in the Tenth Schedule to these By-laws.

(Uniform Building By-Law, 2006, pp. 58, 82) (Original work published in 1984)

Summary (Smoke Detector) :

Smoke detectors and heat detectors in MITEC does fulfill the requirements stated in By-laws under Section 153

and Section 225. Both of the detector are installed on the ceiling level of the lift lobbies area in every floor to

detect fire hazard. They work together with fire alarm bell can be remotely controlled from the fire control room

as well.

Figure 2.57 Smoke and heat detectors in lift lobby

Smoke Detector

Heat Detector](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-46-320.jpg)

![Fire Protection System

Building Services

Active Fire Protection System

Page 35 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part VII: Fire Requirements Fighting Access

[ Section 237 ] Fire Mode of Operation

(1) The fire mode of operation shall be initiated by a signal from the fire alarm panel which

may be activated automatically by one of the alarm devices in the building or manually

Summary (Fire Alarm Control Panel) :

The Fire Alarm Control Panel in MITEC complies with the UBBL 1984 requirements listed under Section

155(1). The fire alarm control panel is equipped with fire mimic diagram for each floor in the building to allow

efficient signal identification during fire emergency

(Uniform Building By-Law, 2006, pp. 85) (Original work published in 1984)

2.1.4.1 Fire Alarm Bell

A fire alarm is an electronic sounder or a bell. The alarm makes a loud, high pitched sound to notify people that

there is a fire in the building. Fire alarms may be activated automatically from smoke detectors, and heat

detectors. When a fire occur, the smoke detector and heat detector will send a signal to the fire alarm control

panel to activate the alarm bell. In MITEC, the alarm bells are installed at escape corridor and car park area. It

provides alert to the occupants in the building and detailed information as to the location of the fire occurred to

meet the needs of firefighting and detection system with central control equipment.

Diagram 2.21 Fire Alarm SystemFigure 2.59 Fire Alarm Bell](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-48-320.jpg)

![2.1.4.2 Manual Call Point

A manual call point is a device which enables personnel to raise an alarm in the event of a fire incident by

pressing a frangible element to activate the alarm system. A fire alarm call point should also be spaced so that

one may always be found within a maximum distance of 30m apart. The manual call points are located nearby

the exits and doorways for the occupants of the building to break the glass therefore a warning signal will then

send to the fire alarm control panel. In MITEC, manual call point were installed at a height of 1.4m above floor

level at easily accessible and conspicuous positions. This includes on exit routes, at the entry floor landing of

staircases and at all exits to the open air. It is a quick means for a person who does not have access privileges to

certain information to gain access when necessary. It is intended to specifically cover emergency cases and the

switch is used to cut electric circuit immediately. User authentication system is used to control and monitor

access to sensitive data. It is designed to preserve security by restricting access.

Fire Protection System

Building Services

Active Fire Protection System

Page 36 Malaysia International Trade

And Exhibition Centre

Exits /

Doorways

Manual Call

Point

Figure 2.60 Indication of location of Manual Call point Figure 2.61 Manual Call Point

UBBL 1984

Part VII: Fire Alarms, Fire Detection, Fire Extinguishment and Firefighting Access

[ Section 237 ] Fire Alarms

(1) Fire alarms shall be provided in accordance with the Tenth Schedule to there By-Laws.

(2) All premises and building with gross floor area excluding car park and storage areas

exceeding 9290 square metres or exceeding 30.5 metres in height shall be provided with a

two-storage alarm system with evacuation (continuous signal) to be given immediately in

the affected section of the premises while an alert (intermittent signal) be given in

adjoining section

(3) Provision shall be made for the general evacuation of the premises by action of master

control

(Uniform Building By-Law, 2006, pp. 85) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-49-320.jpg)

![Fire Protection System

Building Services

Active Fire Protection System

Page 37 Malaysia International Trade

And Exhibition Centre

[ Section 240 ] Electrical isolation switch

(1) Every floor or zone of any floor with a net area exceeding 929 square metres shall be

provided with an electrical isolation switch located within a staircase enclosure to permit

the disconnection of electrical power supply to the relevant floor or zone served

(2) The switch shall be of a type similar to the fireman’s switch specified in Institution of

Electrical Engineers Regulation then in force

Summary (Manual Call Point) :

The fire alarm bell and manual call point used in MITEC complies to the UBBL 1984 requirements listed under

Section 237 (1) , (2) , (3) and Section 240 (1) (2). These systems are placed on every floor of the building at the

escape corridor to allow disconnection of electrical power in any case of emergency.

(Uniform Building By-Law, 2006, pp.85) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-50-320.jpg)

![Fire Protection System

Building Services

Passive Fire Protection System

Page 39 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part VII: Fire Requirements

[ Section 134 ] Designation of purpose groups

For the purpose of this Part every building or compartment shall be regarded according to its use or

intended use as falling within one of the purpose groups set out in the Fifth Schedule to these

By-laws and, where a building is divided into compartments used or intended to be used for

different purposes, the purpose group of each compartment shall be determined separately:

Provided that where the whole or part of the building or compartment, as the case may be, is used or

intended to be used for more than one purpose, only the main purpose of use of that building or

compartment shall be taken into account in determining into which purpose group it falls.

Summary (Purpose Group):

MITEC serves as a place of assembly which offers 13 meeting rooms in various sized that can be configured for

a multitude of functions, such as conference, ballroom, concerts, indoor sports and exhibition hall. The purpose

group of MITEC are compartmented and regarded accordingly while complies with the to the UBBL 1984, Part

VII: Fire Requirements, with the purpose group of IV (Office) and VII (Places of Assembly) The user group

within MITEC is centered around office workers and professionals.

(Uniform Building By-Law, 2006, pp. 45, 46, 47) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-52-320.jpg)

![Summary (Travel Distance to Exit) :

As shown in all the diagrams above, all exit points are arranged within the maximum travel distance for building

occupants to escape the building in the shortest time possible in case of emergency. The spacious concourse area

on ground level able to escort building users escape from the building even during high occupancy level. Other

than the insufficient vertical exit on level 3A which has less occupants since most of the rooms are service

rooms, evacuation routes in MITEC are well-designed and efficiently planned, exit points provided are obvious

and unobstructed at all times. To conclude, the measurement of distance travel to exit within MITEC meets the

requirement stated in By-laws under Section 165 (1), Section 166 (1), (2) and Section 169.

Fire Protection System

Building Services

Passive Fire Protection System

Page 51 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part VII: Fire Requirements

[ Section 165 ] Measurement of travel distance to exits

(1) The travel distance to an exit shall be measured on the floor or other walking surface along

the centre line of the natural path of travel, starting 0.300 metre from the most remote

point of occupancy, curving around any corners or obstructions with 0.300 metre clearance

therefrom and ending at the storey exit. Where measurement includes stairs, it shall be

taken in the plane of the trend noising.

[ Section 166 ] Exits to be accessible at all times

(1) Except as permitted by by-law 167 not less than two separate exits shall be provided from

each storey together with such additional exits as may be necessary.

(2) The exits shall be so sited and the exit access shall be so arranged that the exits are within

the limits of travel distance as specified in the Seventh Schedule to these By-laws and are

readily accessible at all times.

[ Section 169 ] Exit route

No exit route may reduce in width along its path of travel from the storey exit to the final exit.

(Uniform Building By-Law, 2006, pp. 62, 63) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-64-320.jpg)

![Summary (Arrangement of Storey Exit) :

The arrangement of storey exits in MITEC are complies to the restriction stated in By-laws in which the distance

between two storey exits is more than 4.5 metres to ensure a constant and stable flow of circulation. Every storey

exits is provided with a clear escape signage positioned above the fire-rated door. An effective designated

evacuation route required to work with a proper well planned storey exit to maximise the quality of fire escape

route.

Fire Protection System

Building Services

Passive Fire Protection System

Page 53 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part VII: Fire Requirements

[ Section 167 ] Storey exits

(1) Except as provided for in By-laws 194 every compartment shall be provided with at least

two storey exits located as far as practical from each other in no case less than 4.5 metres

and in such position that the travel distances specified in the Seventh Schedule to these

By-laws are not exceeded.

(2) The width of storey exits shall be accordance with the provisions in the Seventh Schedule

to these By-laws.

[ Section 172 ] Emergency exits sign

(1) Storey exits and access to such exits shall be marked by readily visible signs and shall not

be obscured by any decorations, furnishings or other equipment.

(2) Every exit sign shall have the word “KELUAR” in plainly legible letters not less than 150

millimetres high with the principal strokes of the letters not less than 18 millimetres wide.

The lettering shall be in red against a black background.

(3) All exit signs shall be illuminated continuously during periods of occupancy.

[ Section 174 ] Arrangement of storey exits

(1) Where two or more storey exits are required they shall be spaced at not less than 5 metres

apart measured between the nearest edges of the openings.

(2) Each exit shall give access to -

(a) A final exit;

(b) A protected staircase leading to a final exit; or

(c) An external route leading to a final exit.

(3) Basements and roof structures used solely for services need not be provided with

alternative means of egres.

(Uniform Building By-Law, 2006, pp. 63, 64, 65) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-66-320.jpg)

![Summary (Assembly Point) :

MITEC category under Class A place of assembly which able to accommodate up to 60,000 occupants in the

building. Two of the main exits are supported by additional exits on ground floor that lead to assembly point also

complies with Section 183. The assembly point provided within the open parking area located about 50 meters

away from the building which are at a distant from danger. To conclude, the assembly point of MITEC is a

suitable spot to evacuate in case of an emergency which meets the requirement stated in By-laws under Section

178, Section 179 and Section 183 (b), (c) and (d).

Fire Protection System

Building Services

Passive Fire Protection System

Page 55 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part VII: Fire Requirements

[ Section 178 ] Exits for institutional and places of assembly

In building classified as institutional or places of assembly, exits to a street or large open space,

together with staircases, corridors and passages leading to such exits shall be located, separated or

protected as to avoid any undue danger to the occupants of the place of assembly from fire

originating in the other occupancy or smoke therefrom.

[ Section 179 ] Classification of places of assembly

Each place of assembly shall be classified according to its capacity as follows:

Class A - Capacity …… 1,000 persons or more

Class B - Capacity …… 300 to 1,000 persons

Class C - Capacity …… 100 to 300 persons

[ Section 183 ] Exit details for places of assembly

Every place of assembly, every tier or balcony and every individual room used as a place of

assembly shall have exits sufficient to provide for the total capacity thereof as determined in

accordance with by-law 180 and as follows:

(b) doors leading outside the building at ground level or not more than three risers above or

below ground one hundred persons per exit unit;

(c) staircases or other types of exit not specified in by-law 177 above seventy-five persons

per exit unit;

(d) every Class A place of assembly (capacity one thousand persons or more) shall have at

least four separate exits as remote from each other as practicable;

(Uniform Building By-Law, 2006, pp. 66, 67) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-68-320.jpg)

![2.2.2.5 Horizontal Exit

Horizontal exit are the exit discharge occupant to another side of a building along a protected path of egress

travel in a horizontal direction. This category of exit points provide an additional layer of fire resistive protection

from the fire source by using firewall or fire barrier to secure building occupants towards the exit components. In

MITEC, the horizontal exits include the fire fighting lobby, lift lobby, corridor and fire-protected pathway that

lead towards the emergency escape staircase accessed through fire-rated doors. In case of emergency,

compartmented building as MITEC allow building occupants to utilise the fire rated door as a separation from

the origin of fire section to one another.

Fire Protection System

Building Services

Passive Fire Protection System

Page 56 Malaysia International Trade

And Exhibition Centre

Figure 2.77 Horizontal exits access from basement to fire lobby Figure 2.78 Horizontal exit in between basement and lift lobby

UBBL 1984

Part VII: Fire Requirements

[ Section 171 ] Horizontal exits

(1) Where appropriate, horizontal exits may be provided in lieu of other exits.

(2) Where horizontal exits are provided protected staircases and final exits need only be of a

width to accommodate the occupancy load of the larger compartment or building

discharging into it so long as the total number of exit widths provided is not reduced to less

than half that would otherwise be required for the whole building.

(Uniform Building By-Law, 2006, pp. 64) (Original work published in 1984)

Summary (Horizontal Exits) :

Horizontal exits in MITEC meet the requirement stated in By-laws. In reference with the evacuation route, all

horizontal exits are placed in leading to fire escape staircase whilst the ground floor provide sufficient amount of

horizontal exits which can be easily identifies for occupants to egress off the building structure with ease.](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-69-320.jpg)

![Fire Protection System

Building Services

Passive Fire Protection System

Page 60 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part VII: Fire Requirements

[ Section 106 ] Dimensions of staircases

(1) In any staircase, the riser of any staircase shall be not more than 180 millimetres and the

tread shall be not less than 255 millimetres and the dimensions of the rise and the tread of

the staircase so chosen shall be uniform and consistent throughout.

(2) The widths of staircases shall be in accordance with By-laws 168.

(3) The depths of landing shall be not less than the width of the staircases.

[ Section 168 ] Staircases

(1) Except as provided for in By-laws 194 every upper floor shall have means of egress via at

least two separate staircases.

(2) Staircases shall be of such width that in the event of any one staircase not being available

for escape purposes the remaining staircases shall accommodate the highest occupancy

load of any one floor discharging into it calculated in accordance with provisions in the

Seventh schedule to these By-laws.

(3) The required width of a staircase shall be the clear width between walls but handrails may

be permitted to encroach on this width to a maximum of 75 millimetres.

(4) The required width of a staircase shall be maintained throughout its length including at

landings.

(5) Doors giving access to staircase shall be so positioned that their swing shall no point

encroach on the required width of the staircase or landing.

[ Section 198 ] Ventilation of staircase enclosures

(1) All staircases enclosures shall be ventilation at each floor or landing levels by either

permanent openings or openable windows to the open air having a free area of not less

than 1 square metre per floor.

Summary (Vertical Exits) :

All of the vertical exits found in MITEC complies with the By-laws stated in Section 106, Section 168 and

Section 198. Dimension of tread and riser of fire escape staircase are all in suitable and constant length and

width throughout the evacuation route to prevent accident. The 900mm width of fire-rated door create a door

swing that does not intersect with the required width of landing. Designated travelling path keep ventilated and

unobstructed by providing a clear flow of movement during tie of egress as the vertical exits provided in MITEC

act in accordance to the requirement.

(Uniform Building By-Law, 2006, pp. 39, 63, 71) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-73-320.jpg)

![2.2.2.7 Handrail

Rail which designed to be grasped by hand to provide stability and support while ascending or descending

stairways in order to prevent injurious falls. Staircase which more than 4 flights shall be provided with at least

one handrail beside the staircase. Handrails provided in MITEC are mostly embedded directly into the wall

structure while some of the handrail are subjected the ground to achieve a better support for building occupants

Fire Protection System

Building Services

Passive Fire Protection System

Page 65 Malaysia International Trade

And Exhibition Centre

Figure 2.90 Fire escape staircase provided with handrails

UBBL 1984

Part VI: Constructional Requirements

[ Section 107 ] Handrails

(1) Except for staircases of less than 4 risers, all staircases shall be provided with at least one

handrail.

(2) In building other than residential buildings, a handrail shall be provided on each side of the

staircase when the width of the staircase is 1100 millimeters or more.

(3) All handrails shall project not more than 100 millimetres from the face of the finishing wall

surface and shall be located not less than 825 millimetres and not more than 900 millimetres

measured from the nosing of the treads provided that handrails to landings shall not be less

than 900 millimetres from the level of the landing.

(Uniform Building By-Law, 2006, pp. 39) (Original work published in 1984)

Handrail provided on each side of staircase

Wall mounted handrail

Width of staircase : 1200mm

Height of handrail : 900mm

Summary (Handrails) :

Handrails provided in MITEC complies to Section 107 stated in By-laws which width that exceed 1100mm shall

cater with two handrails at each side of the staircase. The height of staircase also maintain within the suitable

range listed in building law with a minimum of 900mm.](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-78-320.jpg)

![Fire Protection System

Building Services

Passive Fire Protection System

Page 70 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part VIII: Fire Requirements

[ Section 136 ] Provision of Compartment Walls and Compartment Floors

Any building, other than a single storey building, of a purpose group specified in the Fifth

Schedule to these By-Laws and which has -

(a) Any storey the floor area of which exceeds that specified as relevant to a building of that

purpose group and height ; or

(b) A cubic capacity which exceeds that specified as so relevant shall be so divided into

compartments, by means of compartment walls or compartment floors or both, that -

(i) No such compartment has any storey the floor area of which exceeds the area specified has a

relevant to that building ; and

(ii) No such compartment has a cubic capacity which exceeds that specified a so relevant to that

building;

Provided that if any building is provided which an automatic sprinkler installation which

complies with the relevant recommendations o the F.OC Rules or Automatic Sprinkler

Installation, 29th edition, this by-law has effect in relation to that building as if the limits of

dimension specified are doubled

[ Section 137 ] Floor in Building exceeding 30 metres in height to be Constructed as

Compartment Floor

In any building which 30 metres in height, any floor which is more than 9 metres above ground

floor level which separates are storey from another storey, other than a floor which is either

within maisonette or a mezzanine floor shall be constructed as a compartment floor

[ Section 139 ] Separation of Fire Risk Areas

The following areas or users shall be separated from the other areas of the occupancy in which

they are located by fire resisting construction of elements of structure of a FRP to be determined

by the local authority based on the degree of hire hazard ;

(a) boiler rooms and associated fuel storage areas](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-83-320.jpg)

![Fire Protection System

Building Services

Passive Fire Protection System

Page 71 Malaysia International Trade

And Exhibition Centre

(b) laundries

(c) Repair shops involving hazardous processes and materials ;

(d) Storage areas of materials in qualities deemed hazardous ;

(e) Liquified petroleum gas storage areas ;

(f) linen rooms ;

(g) Transformer rooms and Substations ;

(h) Flammable liquid stores

[ Section 189 ] Enclosing Means of Escape in Certain Buildings

(1) Every staircase provided under these By-laws in a building of four storey or more, or in a

building where the highest floor level is more than 1200 millimetres above the ground level, or in

any place of assembly, or in any school when such staircase is to be used as an alternative means of

escape shall be enclosed shall be enclosed throughout its length with fire resisting materials.

(2) Any necessary openings, except openings, except openings in external walls which shall not for

the purpose of this by-law include walls to air-wells, in the length of such staircase shall be provided

with self-closing doors constructed of fire-resisting materials.

Summary (Fire Compartmentation) :

The compartmentation of MITEC meets the UBBL 1984 requirements stated. From Diagram 2.59 to Diagram

2.63, the compartation of means of escape and fire risk areas meets the by-laws. MITEC exceed 30 metres

height, therefore, it is required to have compartment floor. Spaces that deemed hazardous are compartmentalize

by fire-resistive components to avoid spread of fire during fire emergency and allow the occupants in the

building to escape.

(Uniform Building By-Law, 2006, pp. 51,52,67) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-84-320.jpg)

![Fire Protection System

Building Services

Passive Fire Protection System

Page 73 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part VII: Fire Requirements

[ Section 162 ] Fire Doors in Compartment walls and separating walls

(1) Fire doors of the appropriate FRP shall be provided

(2) Openings in compartment walls and separating walls shall be protected by a fire door having

a FRP in accordance with the requirements for that wall specified in the Ninth Schedule to

these By-Laws

(3) Openings in protecting structures shall be protected by fire doors having FRP of not less

than half the requirements for the surrounding wall specified in the Ninth Schedules to these

By-Laws but in no case less than half hour

(4) Openings in partitions enclosing a protected corridor or lobby shall be protected by ire doors

having RP of half-hour

(5) Fire doors including frames shall be constructed to a specification which can be shown to

meet the requirements for the relevant FRP when tested in accordance with section 3 of

BS476:1951

[ Section 164 ] Door Closers for Fire Doors

(1) All the fire doors shall be fitted with automatic door closers of the hydraulically spring

operated type in case of sliding doors

(2) Double doors with rebated meeting stiles shall be provided with coordinating device to

ensure that leafs close in the proper sequence

(3) Fire doors may be held open provided the hold open device incorporates a heat actuated

device to release the door. Heat actuated devices shall not be permitted on fire doors

protecting openings to protected corridors or protected staircases

[ Section 173 ] Exit Doors

(1) All exit doors shall be openable from inside without the use of key or any special knowledge

or effort

(2) Exit doors shall close automatically when released and all door devices including magnetic

door holder, shall release the doors upon power failure or actuation of the fire alarm

(Uniform Building By-Law, 2006, pp. 60, 62, 64, 65) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-86-320.jpg)

![UBBL 1984

Part VIII: Fire Requirements

[ Section 143 ] Beam or Column

Any beam or column forming part of, and any structure arrying, and external wall which is required

to be constructed of non-combustible materials shall comply with the provisions of paragraph (3) od

By-Law 142 as to non-combustibility

[ Section 147 ] Construction of Separating wall

(1) Any separating wall, other than a wall separating buildings not divided into compartments

within the limits of size indicated by the letter “X” in Part I of the Ninth Schedule to there

By-Laws, shall be constructed wholly of non-combustible materials, excluding any surface

finish to a wall complies with the requirements of thee By-laws and the required FRP for the

wall shall be obtained without assistance from such non-combustible material

(2) Any beam or column forming part of, and any structure carrying, a separating wall which is

required to be constructed of non-combustible materials shall itself comply with the

requirements of paragraph (1) as to non-combustibility

Fire Protection System

Building Services

Passive Fire Protection System

Page 77 Malaysia International Trade

And Exhibition Centre

(Uniform Building By-Law, 2006, pp. 54, 55) (Original work published in 1984)

Summary (Structural Components) :

The structural components of MITEC have respected the laws of UBBL in the categories stated above.

Therefore, we can conclude that the structure of MITEC is sufficient remain stable while the fire fighters

perform rescue for a certain period of time.

Aluminium Box Top

Caps for Guide Rail

ControllerSide Frame

Guide Rail

End Slat

Aluminium Slats

Diagram 2.68 Components of Fire Roller Shutter

Aluminium Box Bottom](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-90-320.jpg)

![Fire Protection System

Building Services

Passive Fire Protection System

Page 79 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part VIII: Fire Requirements

[ Section 140 ] Fire Appliance Access

All buildings in excess of 7000 cubic metres shall abut upon a street or road or open space of not

less than 12 metres width and accessible to fire brigade appliances. The proportion of the building

abutting the street, road or open spaces shall be in accordance with the following scale :

Summary (Fire Engine Access) :

MITEC has a volume of approximately 1,165,680m³. The width of the neighbouring street for fire fighting

access is 13m. MITEC proportion of building abutting street comply with the 12 metres requirement stated in

By-laws. Hence, there will be a low tendency of slow traffic occur to the fire engine access, facilitating the

rescue attempt during the event of fire

(Uniform Building By-Law, 2006, pp. 52) (Original work published in 1984)

Volume of building in cubic meter Minimum proportions of perimeter of

building

7000 to 28000 One - sixth

2800 to 56000 One - Fourth

56000 to 84000 One - Half

84000 to 112000 Three - Fourths

112000 and above Island Site](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-92-320.jpg)

![Summary (Firefighting Shaft) :

The firefighting shafts in MITEC meets the requirements stated by the UBBL above. The fire lobbies are

well-equipped and the number of lobbies is sufficiently enough to fulfil the overall safety criteria of the building,

Fire Protection System

Building Services

Passive Fire Protection System

Page 83 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part VIII: Fire alarms, fire detection, fire extinguishment and fire fighting access

[ Section 229] Means of access and fire fighting in buildings over 18.3 metres high access

(1) Buildings in which the topmost floor i more than 18.3 metres above fire appliances access

level shall be provided with means of gaining access and fighting fire from within the

building consisting of fire fighting access lobbies, fire fighting staircases, fire lifts and dry

or wet rising systems

(2) Fire fighting access lobbies shall be provided at every floor level and shall be located that

the level distance from the furthermost point of the floor does not exceed 45.75 metres

(3) A fire fighting staircase shall be provided to give direct access to each fire fighting access

lobby and shall be directly accessible from outside the building at fire appliance level. This

may be one of the staircase required as a means of egress from the building

(4) The fire lift shall be discharged directly into the fire fighting access lobby, fire fighting

staircase or shall be connected to it by a protected corridor

(5) A fire lift shall be provided to give access to each fire-fighting access lobby or in the

adsense of a lobby to the fire-fighting staircase at each floor level

(6) The fire lift shall discharge directly into the fire-fighting access lobby fire-fighting staircase

or shall be connected to it by a protected corridor

[ Section 243] Fire Lifts

(1) In a building where the top occupied floor is over 18.5 metres above the fire appliance

access level fire lifts shall be provided

(2) A penthouse occupying not more than 50% of the area of the floor immediately below shall

be exempted from this measurement

(3) The fire lifts shall be located within a separate protected shaft if it opens into a separate

lobby

(4) Fire lifts shall be provided as the rate of one lift in every group of lifts which discharge into

the some protected enclosure or smoke lobby containing the rising main, provided that the

ire lifts are located not more than 61 metres travel distance from the furthermost point of the

floor.

(Uniform Building By-Law, 2006, pp. 83, 86) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-96-320.jpg)

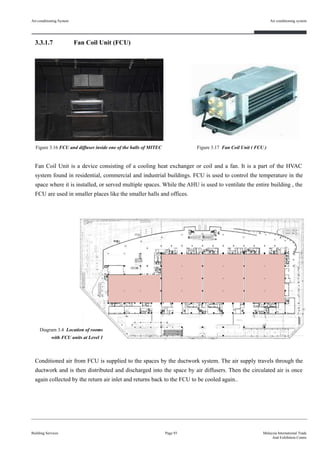

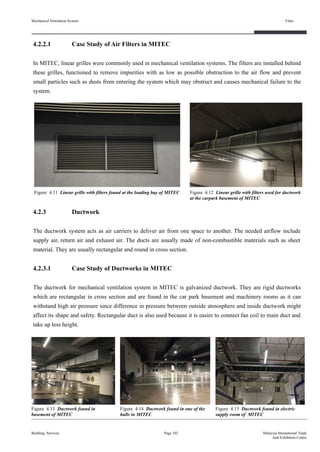

![3.3 Case study of MITEC for Air-Conditioning System

In the MITEC building, there are 2 types of air-conditioning system which are the centralized air-conditioning

system and the split air-conditioning system. The main air-conditioning system is the centralized

air-conditioning while the split air-conditioning system in MITEC is used only in the fire control room and as

backup air-conditioning when the main system is down.

3.3.1 Chilled Water Central Air-Conditioning System

Air-conditioning System

Building Services

Air conditioning system

Page 87 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part III: Space, Light and Ventilation

[ Section 41 ] Mechanical ventilation and air-conditioning (3):

The provisions of the Third Schedule By-Law shall apply to buildings which are mechanically

ventilated or air-conditioned.

Diagram 3.1 Introduction of components in an

air-conditioning system

(Source : Khemani , 2009)

(Uniform Building By-Law, 2006, pp. 18, 19) (Original work published in 1984)

In the MITEC building, majority of the

building is air-conditioned by the chilled

water central air-conditioning system . It

comprises of centralized duct system,

consisting an air handling unit, air supply

system , air return duct and grilled that

circulate warm air from furnace cooled

air to spaces. The warm air from the

spaces is then returned back to the

system to be cooled down again.](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-100-320.jpg)

![3.4 Conclusion

Analysis :

● Air-conditioning system in MITEC are very well maintains and strategically planned out. Machines that

produce very large sounds such as the chillers are placed in the basement away from the halls and

meeting rooms, the interior of the chiller plant room is also covered will paddings of sponges to block of

the sound from causing disturbance.

● Most of the room ventilation are using air-conditioner as the main purpose for the building. There is also

back up electricity machine to store electricity when there is a case of sudden cut off electricity in the

middle of utilizing the rooms. Thus, in any case of air-conditioning is spoilt , mechanical ventilation will

be provided to ventilate the space.

In conclusion, the Chilled Water Central Air Conditioning System and the Split Unit System of MITEC has

compiled with all the By Laws stated in UBBL section 41 as well as MS1525 : 2014 which are the guidelines

for mechanical ventilation and air conditioning set by the government to be followed. With sufficient facilities,

regular maintenance and back-up plans are planned and designed for the halls , meeting rooms and offices, this

ensures the thermal comfort of the environment in MITEC is achieved.

Building Services

Air conditioning system

Page 96 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part III: Space, Light and Ventilation

[ Section 41 ] Mechanical ventilation and air-conditioning

(2) Any application for the waiver of the relevant By-Law shall only be considered if in

addition to the permanent air conditioning system there is provide alternative approved

means of ventilating the air conditioned enclosure, such the within half an hour of the

conditioning system failing, not less than the stipulated volume of the fresh air specified

here in after shall introduced into the enclosure during the period of air conditioning system

is not functioning.

Air-conditioning System

(Uniform Building By-Law, 2006, pp. 18) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-109-320.jpg)

![Mechanical Ventilation System

Building Services

Staircase pressurisation system

Page 111 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part VII: Fire Requirements

[ Section 198] Ventilation of staircase enclosures

(1) All staircase enclosures shall be ventilated at each floor of landing level by either permanent

openings or openable windows to the open air having a free area of not less than 1 square

metre per floor.

[ Section 202 ] Pressurized system for staircase

All staircases serving buildings of more than 47.75 metres in height where there is no adequate

ventilation as required shall be provided with a basic system of pressurization--

(a) Where the air capacity of the fan shall be sufficient to maintain an air flow of not less than

60 metres per minute through the doors which are deemed to be open;

(b) Where the number of doors which are deemed to be opened at the one time shall be 10% of

the total number of doors opening into the staircase with a minimum number of two doors

open;

(c) Where with all the doors closed the air pressure differential between the staircases and the

areas served by it shall not exceed 5 millimetres water gauge.

(d) Where the mechanical system to prevent smoke from entering the staircases shall be

automatically activated by a suitable heat detecting device, manual or automatic alarm or

automatic wet pipe sprinkler system;

(e) Which meets the functional requirements as may be agreed with the D.G.F.S.

Summary :

The staircase pressurization system in MITEC meets the requirement stated in UBBL 1984 under section 202.

The pressurization system is provided for each enclosed staircase in the building. It is well-maintained and still

functioning to supply air from outside to pressurize the stairwell during fire emergency.

The natural ventilated staircase in MITEC has fulfil the UBBL requirements of which vent louvres can achieve

the same purposes of securing air circulation without the necessary to install a pressurized system for staircase.

(Uniform Building By-Law, 2006, pp. 71, 72) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-124-320.jpg)

![Mechanical Ventilation System

Building Services

Lift lobby pressurisation system

Page 113 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part VII: Fire Requirements

[Section 150] Protected shafts

1) No protected shaft shall be constructed for use for any purposes additional to those specified

in this Part other than for the accomodation of any pipe or duct, or as sanitary

accommodation or washrooms, or both.

2) Subject to the provisions of this Part, any protected shaft should be completed enclosed.

There shall be no opening in any protecting structure other than any one or more of the following:

(d) If the protected shaft serves as, or contains a ventilating duct, an inlet to outlet from the duct or

an opening for the duct.

[Section 197] Protected lobbies

1. Protected lobbies shall be provided to serve staircases in buildings exceeding 18 metres

above ground level where the staircase enclosures are not ventilated through the external

walls

2. In buildings exceeding 45 metres above ground level, such protected lobbies shall be

pressurised to meet the requirements of Section 7 of the Australian Standard 1668, Part

1-1974 or any other system meeting the functional requirement of the D.G.F.S

3. Protected lobbies may be omitted the staircase enclosures are pressurized to meet the

requirements of by-law 200.

Summary :

The lift lobby pressurization system in MITEC meets the requirement stated in UBBL 1984 under section 150

and section 197. The protected lift lobby is pressurized to ease fire-fighting operation to be carried out during the

case of emergency.

(Uniform Building By-Law, 2006, pp. 57, 71) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-126-320.jpg)

![Mechanical Ventilation System

Building Services

Basement car park exhaust system

Page 116 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part VIII: Fire Alarms, Fire Detection, Fire Extinguishment and Fire Fighting Access

[ Section 249 ] Smoke and heat venting

In windowless buildings, underground structures and large factories, smoking venting facilities shall

be provided for the safe use of exit.

Third schedule

7- Mechanical ventilation systems in basement areas

(1) Basement and other enclosures below ground level used for working areas or for occupancy

of more than two hours duration shall be provided with mechanical ventilation having a

minimum of six air changes per hour.

(2) Basement or underground car parks shall be provided with mechanical ventilation such that

the air exhausted to the external atmosphere should be constitute not less than six air

changes per hours. AIr extract opening shall be arranged such that it is not less than 0.5

metres above the floor level period system.

(3) Basement and other enclosures below ground level used for working areas or for occupancy

of more than two hours duration shall be provided with a minimum of one fresh air change

per hour, or the minimum of 0.28mm per person working in such area.

(Uniform Building By-Law, 2006, pp. 87) (Original work published in 1984)

Figure 4.36 Induced jet fan found in the basement car park Figure 4.37 Ductwork in the basement carpark](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-129-320.jpg)

![UBBL 1984

Part VIII: Fire Alarms, Fire Detection, Fire Extinguishment and Fire Fighting Access

[ Section 249 ] Smoke and heat venting

In windowless buildings, underground structures and large factories, smoking venting facilities shall

be provided for the safe use of exit.

[ Section 250 ] Natural draught smoke ventilation

(1) Natural draught smoke venting shall utilize roof vents or vents in walls at or near the ceiling

level.

(2) Such vents shall normally be in open positions of they are closed they shall be so designed

to open automatically by an approved means in the events of a fire.

[ Section 251 ] Smoke vents to be adequate to prevent dangerous accumulation of smoke.

When smoke venting facilities are installed for purposes of exit safety in accordance with the

requirements of this Part they shall be adequate to prevent dangerous accumulation of smoke during

the period of time necessary to evacuate the area served using available exit facilities with a margin

of safety to allow for unforeseen contingencies.

Mechanical Ventilation System

Building Services

Lift motor room extract system

Page 119 Malaysia International Trade

And Exhibition Centre

Summary:

MITEC complies by the UBBL 1984 requirements for its ventilation system in aiding and providing regulated

air in concern for property damage as well as occupant safety. The ventilation concludes the requirement of the

section of 249, section 250 and section 251 as regards to the diagrams and figures above stating as the basement

carpark is fitted with necessity of an exhaust system to extract and disperse smoke, and harmful air particles

during a fire emergency.

(Uniform Building By-Law, 2006, pp. 87) (Original work published in 1984)](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-132-320.jpg)

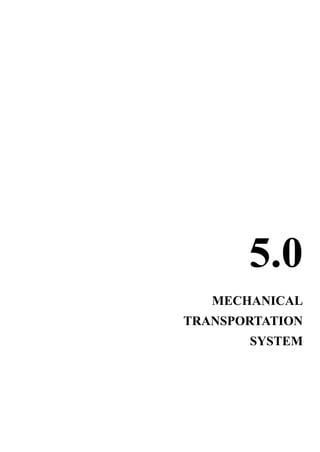

![5.3.1 Case Study of Lifts in MITEC

5.3.1.1 Overview

There are ten locations in MITEC where lifts can be found, summing up to 17 lifts altogether, of which 15 are

passenger lifts and two are freight lifts. Even though the building only has three main superstructure levels,

another three mezzanine floors for each level and two basement levels, the amount of lifts are necessary to

respond to the nature of the building as an international exhibition centre that needs to accommodate huge

numbers of visitors almost daily, and also to ensure sufficient circulation points are provided within the large

building.

5.3.1.1.1 Passenger Lift

There are two different models of passengers lift in MITEC. The first type is the commonly seen lift that is

embedded into the walls of the building, whereas the second type is a see-through glass lift that is also

considered the centrepiece of the building.

● Type of elevator: Gearless traction elevator

● Brand: KONE

● Registered number: WP PMA 24034

● Capacity of person: 24 person

● Capacity of kilogram: 1576kg

● Rated speed: 1.0 - 1.75 m/s

● Car Height: 2400mm

● Entrance Opening: 1500x2100mm

● Type of entrance: 2-panel central opening

Building Services

Case Study of Lifts in MITEC

Page 132 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part VI: Construction Requirements

[ Section 124 ] Lifts

For non-residential buildings exceeding 4 storeys above or below the main access level at least one

lift shall be provided.

Figure 5.16 Passenger lift and fire lift placed together

(Uniform Building By-Law, 2006, pp. 43) (Original work published in 1984)

Mechanical Transportation System](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-145-320.jpg)

![Building Services Page 150 Malaysia International Trade

And Exhibition Centre

UBBL 1984

Part VII: Fire Requirements

[ Section 153 ] Smoke detectors for lift lobbies

(1) All lift lobbies shall be provided with smoke detectors.

[ Section 154 ] Emergency mode of operation in event of main power failure

(1) On failure of main power lifts shall return in sequence directly to the designated floor,

commencing with the fire lifts, without answering any car or landing calls and park with

doors open.

[ Section 155 ] Fire mode of operation

(2) If main power is available all lifts shall return in sequence directly to the designated floor,

commencing with the fire lifts, without answering any car or landing calls, overriding the

emergency stop button inside the car, but not any other emergency or safety devices, and

park with doors open.

(3) The fire lifts shall be available for use by the fire brigade on operation of the fireman’s

switch.

(4) Under this mode of operation, the fire lifts shall only operate in response to car calls but not

to landing calls in a mode of operation in accordance with by-law 154.

Part VIII: Fire Alarms, Fire Detection, Fire Extinguishment and Fire Fighting Access

[ Section 229 ] Means of access and fire fighting in buildings over 18.3 metres high

(5) A fire lift shall be provided to give access to each fire fighting access lobby or in the

absence of a lobby to the fire fighting staircase at each floor level.

(Uniform Building By-Law, 2006, pp. 58, 83) (Original work published in 1984)

Mechanical Transportation System Safety Features of Lift](https://image.slidesharecdn.com/finalisedb-190727174357/85/MITEC-Building-Service-System-163-320.jpg)

![4. VRF or VRV ? Learn About The Differences And VRF System Design. (n.d.). Retrieved from

https://coolautomation.com/wiki/vrv-or-vrf/

5. Khemani, H. (2018, November 12). Chilled Water Central Air Conditioning Plants. Retrieved from

https://www.brighthubengineering.com/hvac/50160-chilled-water-central-air-conditioning-systems/

6. Suvo. (2018, November 12). Understanding Central Air Conditioning and Heating Systems. Retrieved

from

https://www.brighthubengineering.com/hvac/104486-working-with-central-air-conditioning-and-heat-pu

mps/

7. Chilled Water System Basics [HVAC Commercial Cooling]. (2019, May 09). Retrieved from

https://highperformancehvac.com/chilled-water-system-basics/

8. How Air Conditioners Work. (2011, June 28). Retrieved from https://home.howstuffworks.com/ac4.htm

9. Chilled Water Air Conditioning Principles And Applications. (n.d.). Retrieved from

https://www.airconditioning-systems.com/chilled-water-air-conditioning.html

10. Thermal Care, Inc. (n.d.). Thermal Care, Inc. Retrieved from

https://www.thermalcare.com/how-does-a-chiller-work/

11. Air Handling Unit. (n.d.). Retrieved from

https://www.airconditioning-systems.com/air-handling-unit.html

12. Ravti, & Ravti. (2016, September 10). Equipment - Air Handling Units (AHU). Retrieved from

https://blog.ravti.com/equipment-air-handling-units-ahu-4900e8b85f83

13. Functions of An Air Handling Unit And Its Components. (n.d.). Retrieved from

http://www.mynewsdesk.com/in/pressreleases/functions-of-an-air-handling-unit-and-its-components-71

8365

14. Evans, P. (2019, May 20). How Air Handling Units work. Retrieved from

https://theengineeringmindset.com/air-handling-units-explained/

15. Fan Coil Unit Systems. (n.d.). Retrieved from :

https://www.betterbuildingspartnership.com.au/information/fan-coil-unit-systems/

16. What's a Split Air Conditioner? | Split vs Packaged AC Units. (2018, June 17). Retrieved from

https://asm-air.com/airconditioning/what-is-a-split-air-conditioner/

17. Khemani, H. (2018, November 12). Parts of Split Air Conditioners: Outdoor Unit. Retrieved from

https://www.brighthubengineering.com/hvac/45044-parts-of-the-split-air-condioners-outdoor-unit/

18. Khemani, H. (2018, November 12). Types of Air Conditioning Systems: Window, Split, Packaged and

Central. Retrieved from

https://www.brighthubengineering.com/hvac/897-types-of-air-conditioning-systems/