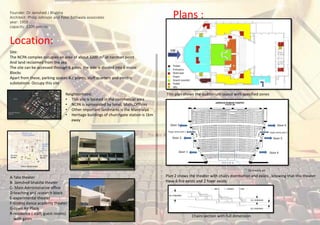

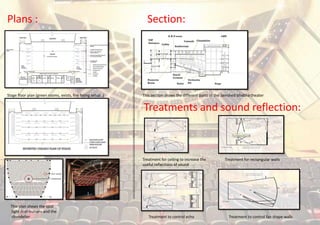

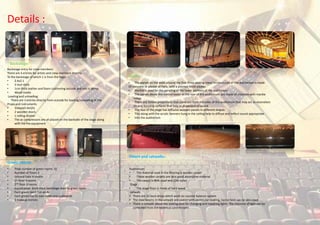

The Jamshed Bhabha Theatre is located within the NCPA complex in Mumbai, India. It was built in 1959 and has a capacity of 1,109 people. The theatre occupies an area of about 3,200 square meters on land reclaimed from the sea. It is surrounded by hotels, malls, and offices and located near important landmarks. The theatre has detailed plans showing the auditorium layout, seating arrangement, and backstage areas. It also has green rooms, a control room to operate lighting and sound, and technical features in the walls, floors, and catwalks to enhance acoustics.