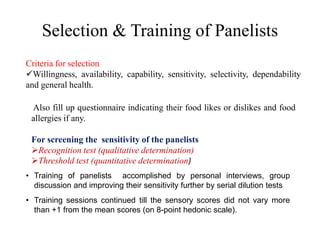

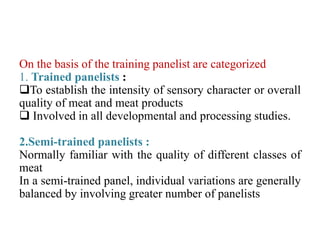

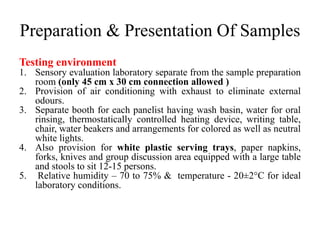

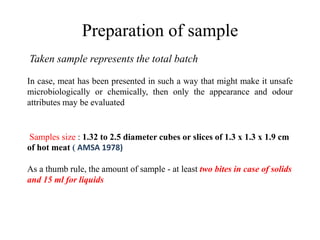

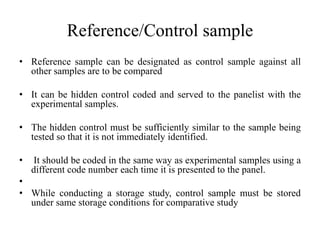

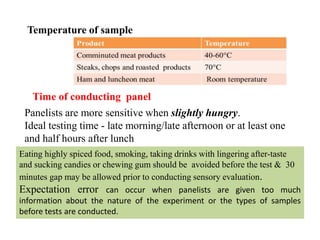

This document discusses the selection and training of sensory panelists. It outlines criteria for selecting panelists, including willingness and health. Panelists undergo screening and training tests to improve their sensitivity. Trained panelists evaluate intensity and quality, while semi-trained panelists are familiar with meat quality. The document also describes best practices for preparing, presenting, coding and serving samples to panelists in a controlled sensory laboratory environment. Reference samples are included to compare to experimental samples. Ideal conditions include temperature, lighting and limiting factors that could influence panelist responses.