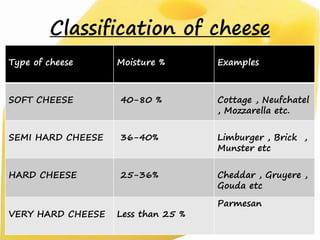

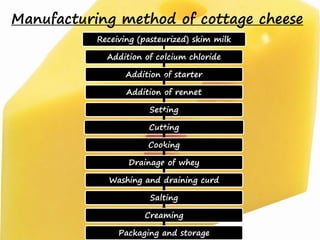

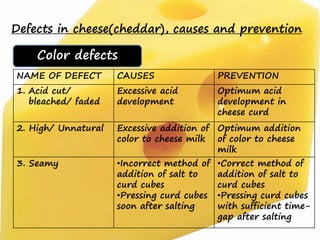

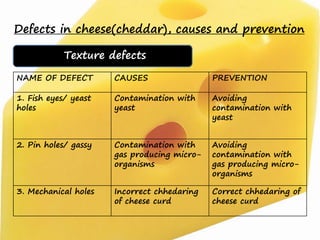

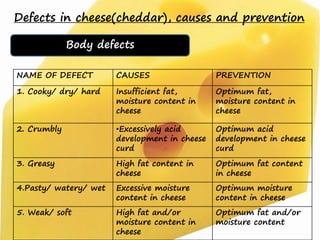

This document presents information about cheese from a presentation given by Ankur Gupta. It defines cheese and describes its classification based on moisture content, including soft, semi-hard, hard, and very hard cheeses. The general manufacturing process for cheese is outlined involving steps like coagulation, curd preparation, pressing, salting, and ripening. Specific methods for making cottage cheese and cheddar cheese are also summarized. Common defects in cheddar cheese and their causes are listed. Popular cheese brands in India are noted along with Amul being a major brand. The conclusion restates that cheese is obtained from milk through coagulation and draining and that acceptability remains a concern for some due to the use of rennet.