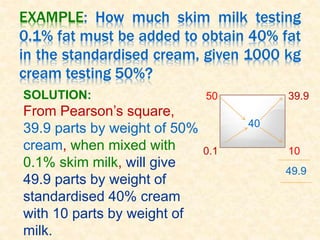

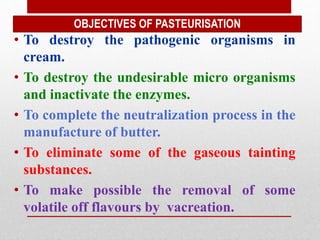

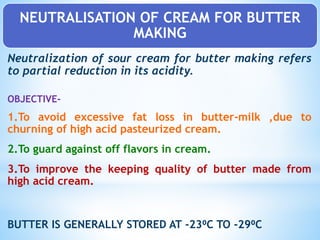

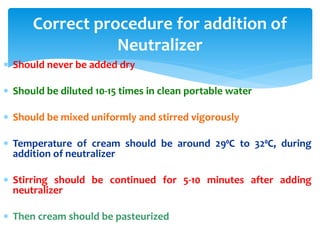

This document discusses standardization, pasteurization, and neutralization of cream for butter making. Standardization involves adjusting the fat content of cream to a desired percentage using skim milk. Pasteurization heats every particle of cream to over 71°C to destroy pathogens and enzymes. Neutralization partially reduces the acidity of sour cream to avoid excessive fat loss during churning and improve butter quality. The proper use of lime or sodium bicarbonate as neutralizers and achieving the correct churning acidity are emphasized.