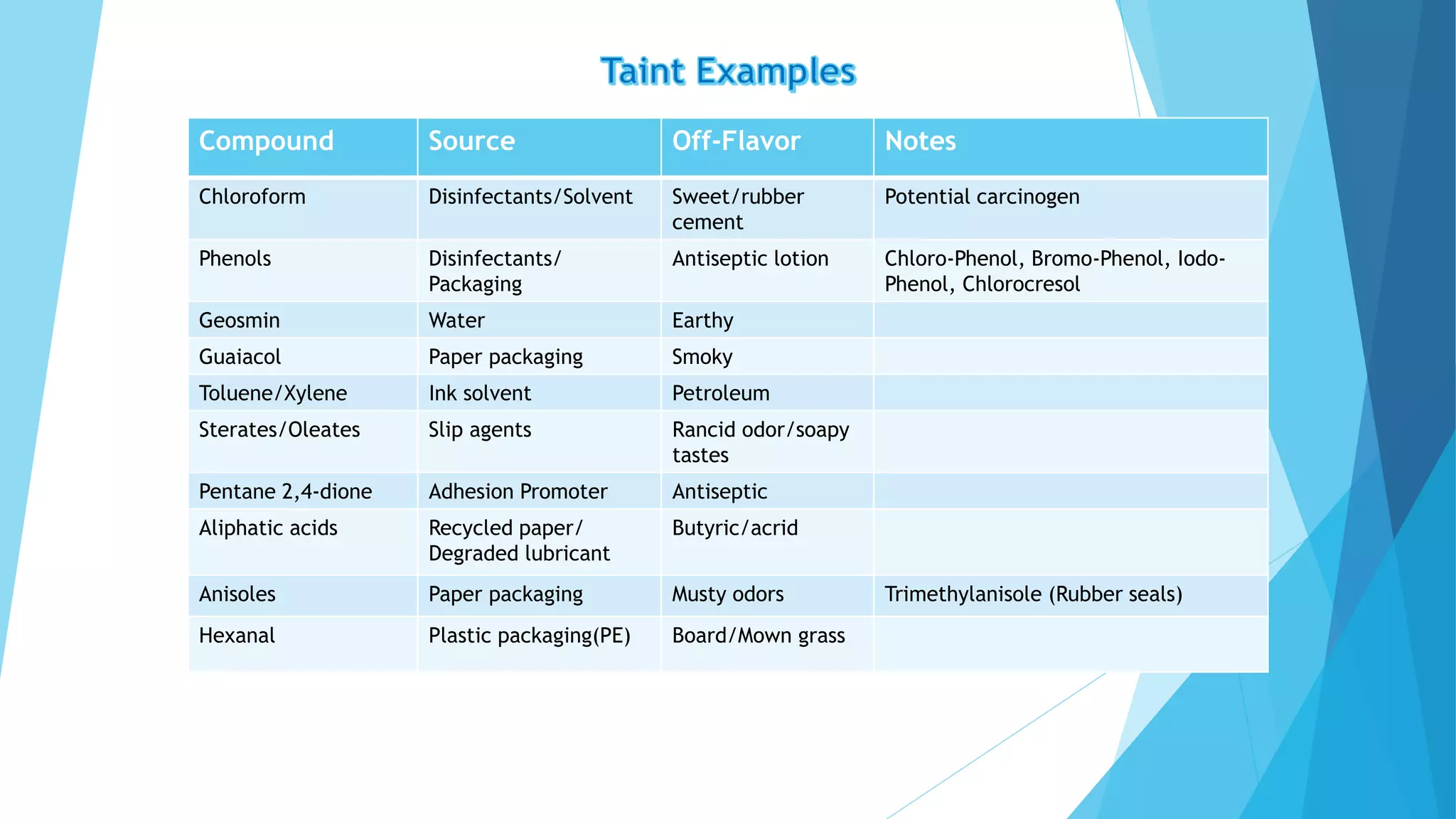

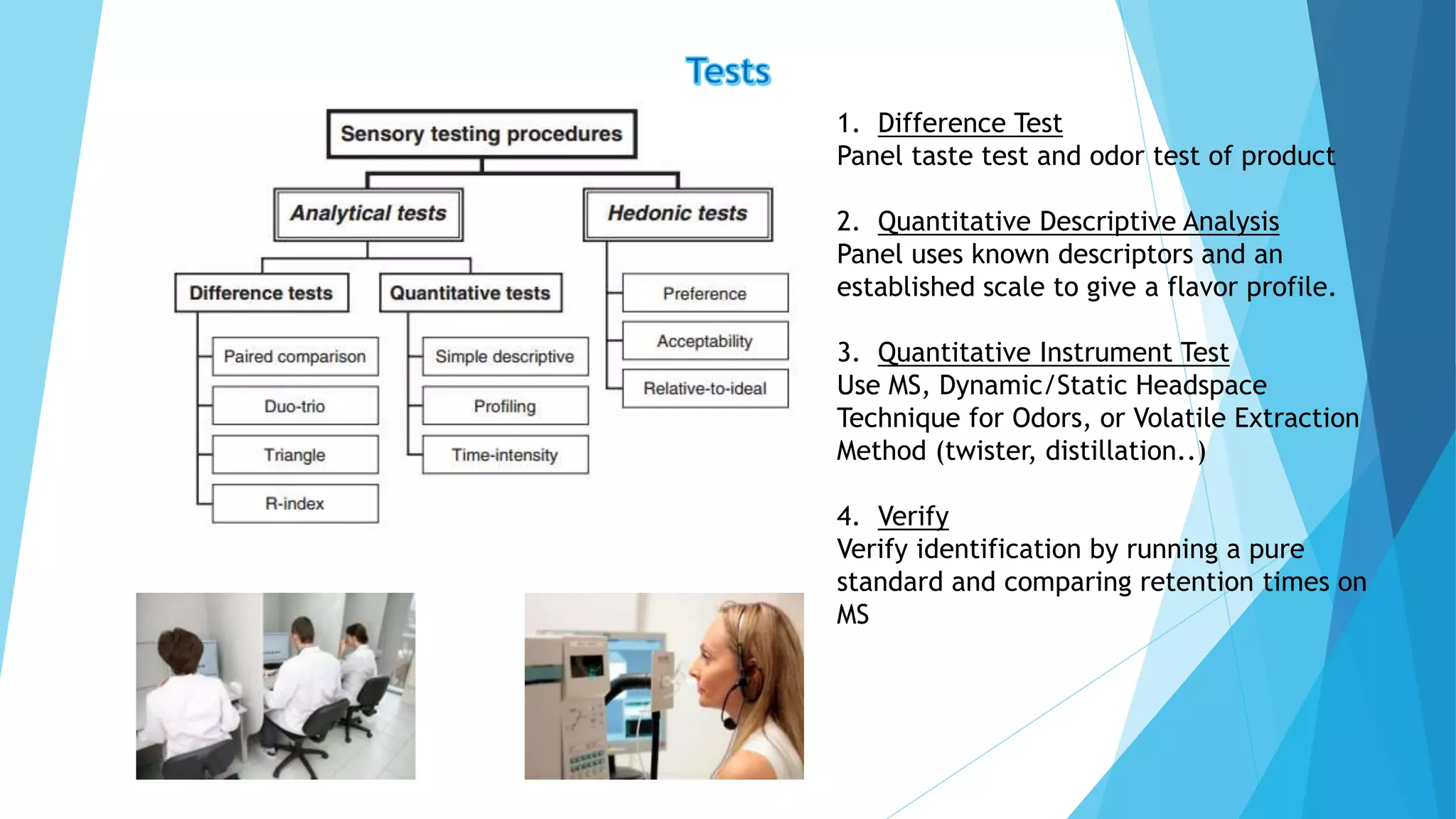

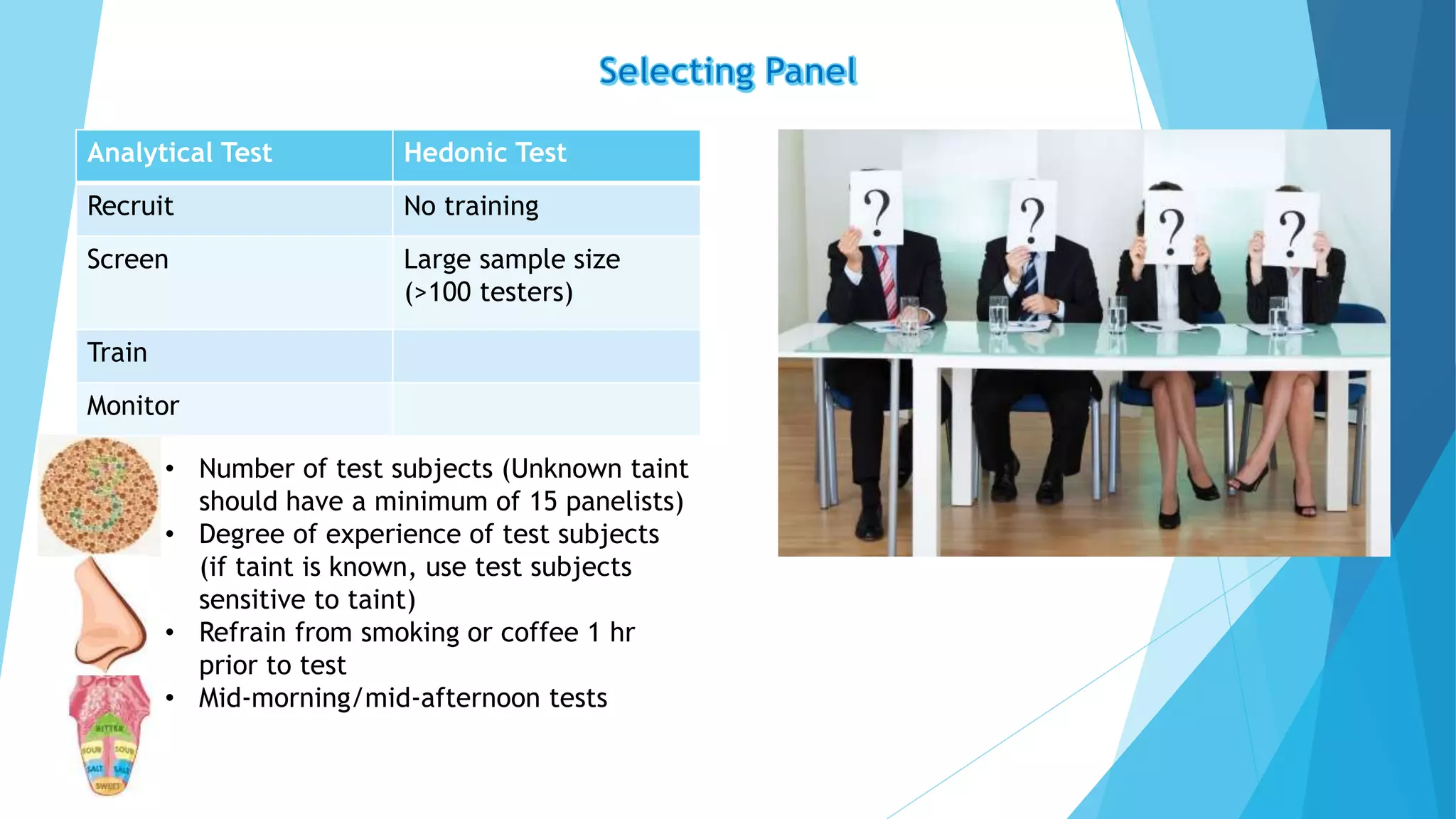

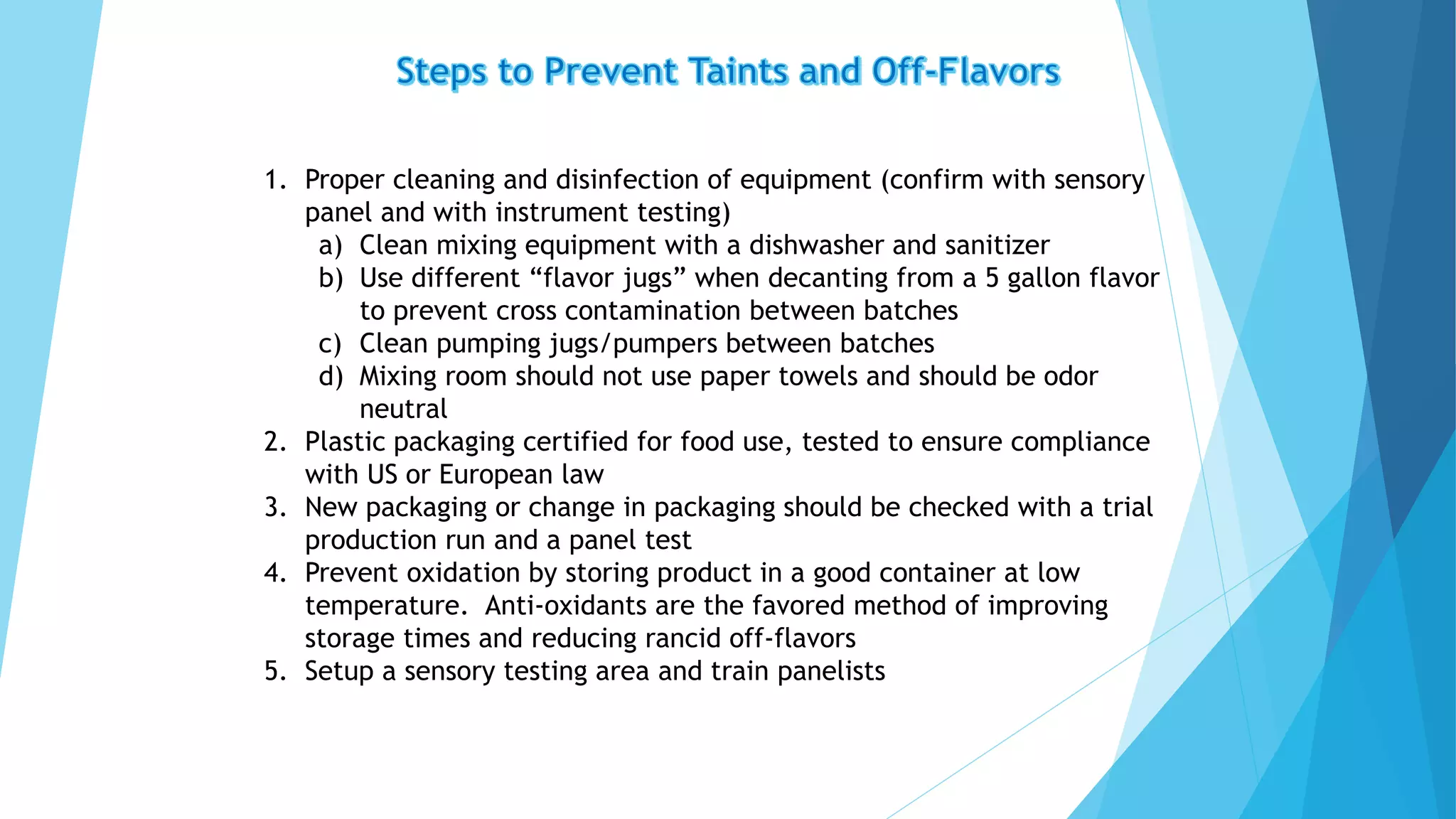

1. Proper cleaning and disinfection of equipment is essential to prevent food taint from cleaning agents. Sensory testing of equipment and materials is recommended.

2. Packaging materials must be certified for food use and tested to ensure they do not introduce off-flavors. Changes in packaging require testing.

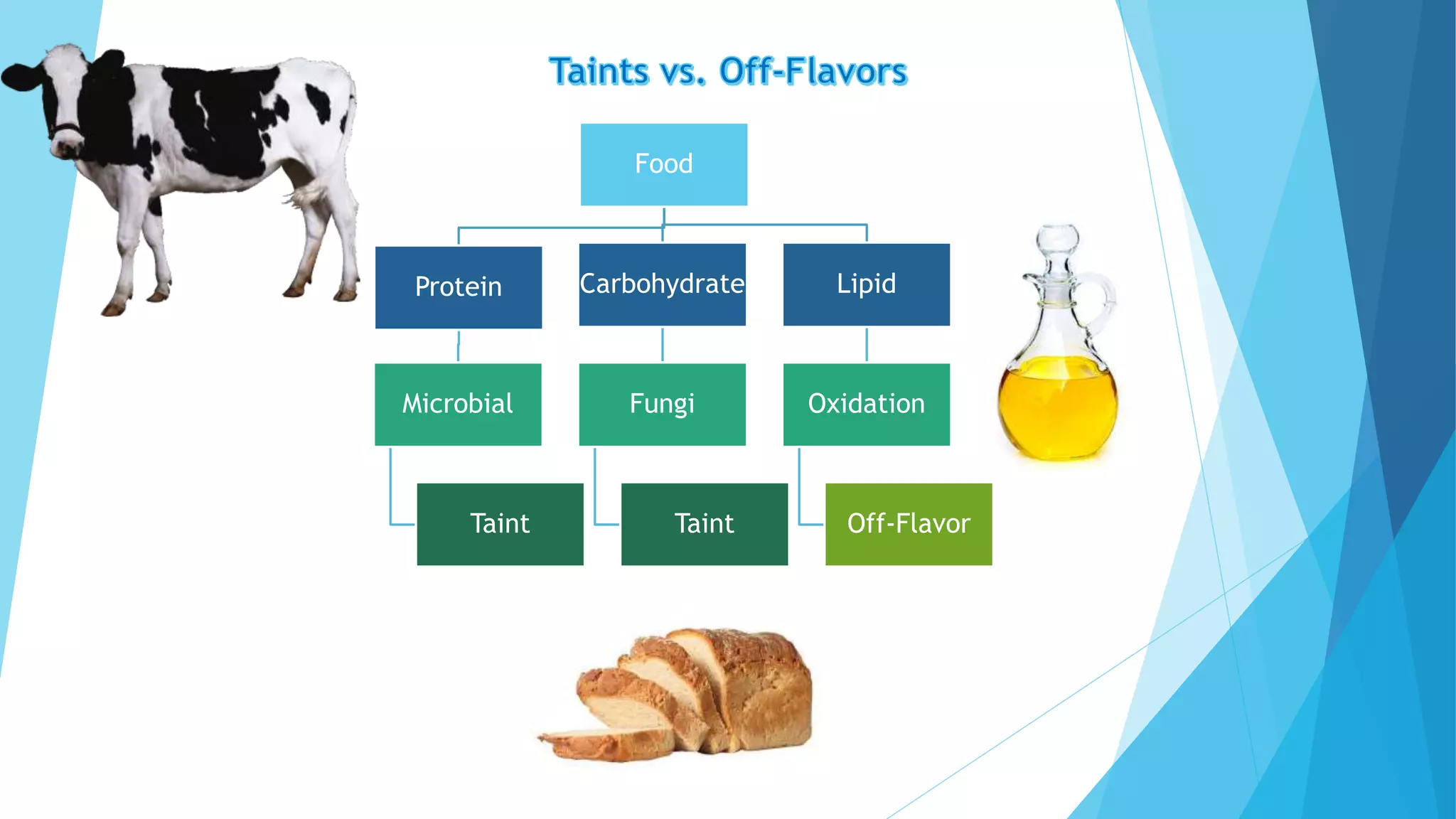

3. Oxidation can be reduced by proper storage of products at low temperatures with anti-oxidants to extend shelf life and reduce rancidity.