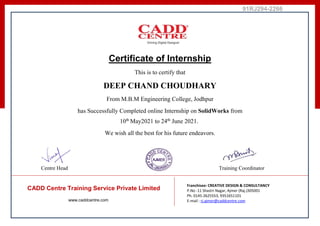

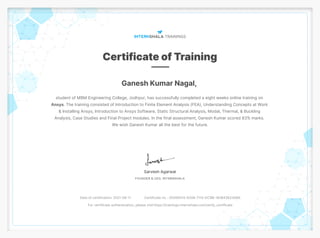

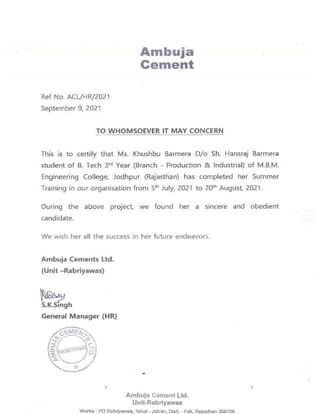

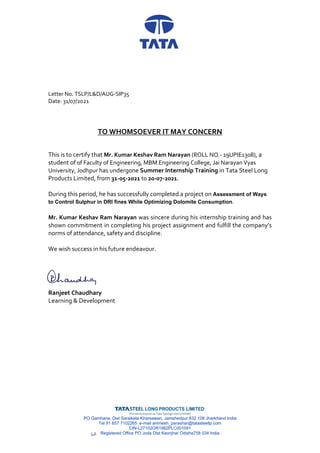

The document contains multiple internship certificates and training completions for students from MBM Engineering College, Jodhpur, detailing their successful completion of various online and onsite programs in fields such as SolidWorks, logistics optimization, and 3D printing. Each certificate highlights the student’s performance, duration of training, and project details, underscoring their future readiness in their respective domains. The document also includes a summer internship report focused on Ambuja Cement Limited, outlining the company's history, organizational structure, and the student's analysis of its operations.

![14

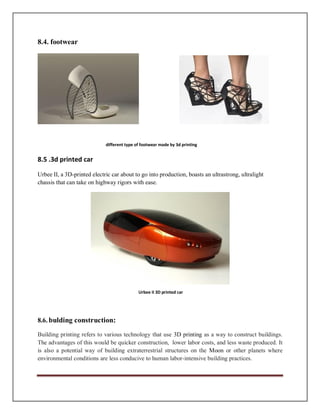

Clientele:

Being a client centric organisation ,we make sure to offer our client

customized solutions so as to garner complete customer satisfaction at client as

well as our end.in order to manufacture an optimum range of products ,we

make use of the high quality raw materials and offer our products at market

leading prices due to these reasons ,we have been able to form a large client

base across the global the department of housing and community development

prepared and certified an environmental impact statement resulting in a

recommendation that the commission adopt and approve the use of cpvc. The

commission‘s vote was unanimous and cpvc has been pieced in the

2007california plumbing code

IN the united states and Canada, pvc pipes account for the largest majority

of pipe materials used in buried municipal applications for drinking water

district buttons and wastewater mains.[22] buried PVC pipes in both water and

sanitary sewer applications that are 4 inches (100mm) in diameter and larger

are typically joined by means of a gasket-sealed joint .the most common type

of gasket utilized in north America is a metal reinforced elastomer ,commonly

referred to as a rieber sealing system.](https://image.slidesharecdn.com/1-240422043147-bfcd0900/85/Internship-report-on-mechanical-engineering-61-320.jpg)

![iii. Drag to reposition the model.

iv. Release the button on your pointing device to return to the wheel.

b. To pan using the middle mouse button or the mouse wheel.

i. Press and hold down the scroll wheel or middle button. The cursor changes to the Pan cursor.

ii. Drag to reposition the model.

iii. Release the wheel or button on your mouse.

C. Orbit

i. Display one of the View Object or Full Navigation wheels.

ii. Click and hold down the Orbit wedge The cursor changes to the Orbit cursor.

iii. Drag to rotate the model

iv. Release the button on vour mouse.

NE: To navigate to the zoom, pan or orbit toos, go to:

a. View tab navigate panelzoomor

b. View tabo navigate panel pan or

c. View tab navigate paneb orbit.

7. DRAWING UNITS LIMITS

• UNITS

The format, precision, and other settings used to display coordinates, distances, and angles are set through this dialog box, and

are saved in the current drawing. It is recommended that you save these settings to your drawing template files to reduce your

setup time when you start a new drawing. The Drawing Units dialog box is displayed. Enter -units at the Command prompt to

display options.

• Limits:

When you start a new draw ing. and then decide how much space I need for my drawing. Think of it as the size of vour

drawing area. Then you can define draw mgIimitscomectly. Type LIMITS enter. Type 0,0 as lower left comer then type or

click the coordinate for upper right corner based on the units which is in Inches or mm.

• Command: LIMITS

Reset Model space limits:

Specify lower left corner or (ON/OFF] 0.0000, 0.0000:0,0

Specify upper right corner 100.0000, 100.0000: 300,200

8. COMMANDS](https://image.slidesharecdn.com/1-240422043147-bfcd0900/85/Internship-report-on-mechanical-engineering-109-320.jpg)

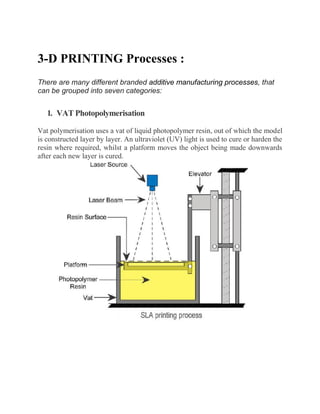

![matured and it became clear that soon metal removal would no longer be the sole occupant of the

aforementioned paradigm. It was during this decade that the term subtractive manufacturing

appeared for the large family of machining processes with metal removal as their common theme.

However, at the time, the term 3D printing still referred only to the polymer technologies in most

minds, and the term AM was likelier to be used in metalworking contexts than among

polymer/inkjet/stereo lithography enthusiasts.

By the early 2010s, the terms 3D printing and additive manufacturing developed senses in which they

were synonymous umbrella terms for all AM technologies. Although this was a departure from their

earlier technically narrower senses, it reflects the simple fact that the technologies all share the

common theme of sequential-layer material addition/joining throughout a 3D work envelope under

automated control. (Other terms that have appeared, which are usually used as AM synonyms have

beendesktop manufacturing, rapid manufacturing [as the logical production-level successor to rapid

prototyping], and on-demand manufacturing [which echoes on-demand printing in the 2D sense of

printing].) The 2010s were the first decade in which metal parts such as engine brackets and large

nutswould be grown (either before or instead of machining) in job production rather than

obligatory being machined from bar stock or plate. The term subtractive has not replaced

the term machining, instead complementing it when a term thatcovers any removal method is needed.](https://image.slidesharecdn.com/1-240422043147-bfcd0900/85/Internship-report-on-mechanical-engineering-152-320.jpg)

![Selective Laser Melting (SLM) does not use sintering for the fusion of powder granules but will

completely melt the powder using a high-energy laser to create fully dense materials in a layer- wise

method that has mechanical properties similar to those of conventional manufacturedmetals.

Electron beam melting (EBM) is a similar type of additive manufacturing technology for metal parts

(e.g. titanium alloys). EBM manufactures parts by melting metal powder layer by layer with an

electron beam in a high vacuum. Unlike metal sintering techniques that operate below melting point,

EBM parts are fully dense, void-free, and very strong.

Another method consists of an inkjet 3D printing system. The printer creates the model one layerat a

time by spreading a layer of powder (plaster, or resins) and printing a binder in the cross- section of

the part using an inkjet-like process. This is repeated until every layer has been printed. This

technology allows the printing of full color prototypes, overhangs, and elastomer parts. The strength

of bonded powder prints can be enhanced with wax or thermoset polymer impregnation.

Lamination

In some printers, paper can be used as the build material, resulting in a lower cost to print. During

the 1990s some companies marketed printers that cut cross sections out of special adhesive coated

paper using a carbon dioxide laser and then laminated them together.

In 2005, Mcor Technologies Ltd developed a different process using ordinary sheets of office paper,

a Tungsten carbide blade to cut the shape, and selective deposition of adhesive and pressure to bond

the prototype.[36]

There are also a number of companies selling printers that print laminated objects using thin plastic

and metal sheets

Photo polymerization

Stereo lithography was patented in 1986 by Chuck Hull. Photo polymerization is primarily used in

stereo lithography (SLA) to produce a solid part from a liquid. This process dramatically redefined

previous efforts, from the photosculpture method of François Willème (1830–1905) in 1860

through the photopolymerization of Mitsubishi's Matsubara in 1974. The photosculpture method

consisted of photographing a subject from a variety of equidistant angles and projecting each

photograph onto a screen, where a pantagraph was used to trace the outline onto modeling clay)](https://image.slidesharecdn.com/1-240422043147-bfcd0900/85/Internship-report-on-mechanical-engineering-160-320.jpg)

![matured and it became clear that soon metal removal would no longer be the sole occupant of the

aforementioned paradigm. It was during this decade that the term subtractive manufacturing

appeared for the large family of machining processes with metal removal as their common theme.

However, at the time, the term 3D printing still referred only to the polymer technologies in most

minds, and the term AM was likelier to be used in metalworking contexts than among

polymer/inkjet/stereo lithography enthusiasts.

By the early 2010s, the terms 3D printing and additive manufacturing developed senses in which they

were synonymous umbrella terms for all AM technologies. Although this was a departure from their

earlier technically narrower senses, it reflects the simple fact that the technologies all share the

common theme of sequential-layer material addition/joining throughout a 3D work envelope under

automated control. (Other terms that have appeared, which are usually used as AM synonyms have

beendesktop manufacturing, rapid manufacturing [as the logical production- level successor to rapid

prototyping], and on-demand manufacturing [which echoes on-demand printing in the 2D sense of

printing].) The 2010s were the first decade in which metal parts such as engine brackets and large

nutswould be grown (either before or instead of machining) in job production rather than

obligatory being machined from bar stock or plate. The term subtractive has not replaced

the term machining, instead complementing it when a term thatcovers any removal method is needed.](https://image.slidesharecdn.com/1-240422043147-bfcd0900/85/Internship-report-on-mechanical-engineering-178-320.jpg)

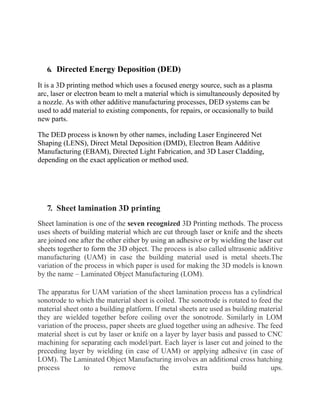

![Selective Laser Melting (SLM) does not use sintering for the fusion of powder granules but will

completely melt the powder using a high-energy laser to create fully dense materials in a layer- wise

method that has mechanical properties similar to those of conventional manufacturedmetals.

Electron beam melting (EBM) is a similar type of additive manufacturing technology for metal parts

(e.g. titanium alloys). EBM manufactures parts by melting metal powder layer by layer with an

electron beam in a high vacuum. Unlike metal sintering techniques that operate below melting point,

EBM parts are fully dense, void-free, and very strong.

Another method consists of an inkjet 3D printing system. The printer creates the model one layerat a

time by spreading a layer of powder (plaster, or resins) and printing a binder in the cross- section of

the part using an inkjet-like process. This is repeated until every layer has been printed. This

technology allows the printing of full color prototypes, overhangs, and elastomer parts. The strength

of bonded powder prints can be enhanced with wax or thermoset polymer impregnation.

Lamination

In some printers, paper can be used as the build material, resulting in a lower cost to print. During

the 1990s some companies marketed printers that cut cross sections out of special adhesive coated

paper using a carbon dioxide laser and then laminated them together.

In 2005, Mcor Technologies Ltd developed a different process using ordinary sheets of office paper,

a Tungsten carbide blade to cut the shape, and selective deposition of adhesive and pressure to bond

the prototype.[36]

There are also a number of companies selling printers that print laminated objects using thin plastic

and metal sheets

Photo polymerization

Stereo lithography was patented in 1986 by Chuck Hull. Photo polymerization is primarily used in

stereo lithography (SLA) to produce a solid part from a liquid. This process dramatically redefined

previous efforts, from the photosculpture method of François Willème (1830–1905) in 1860

through the photopolymerization of Mitsubishi's Matsubara in 1974. The photosculpture method

consisted of photographing a subject from a variety of equidistant angles and projecting each

photograph onto a screen, where a pantagraph was used to trace the outline onto modeling clay)](https://image.slidesharecdn.com/1-240422043147-bfcd0900/85/Internship-report-on-mechanical-engineering-186-320.jpg)

![matured and it became clear that soon metal removal would no longer be the sole occupant of the

aforementioned paradigm. It was during this decade that the term subtractive manufacturing

appeared for the large family of machining processes with metal removal as their common theme.

However, at the time, the term 3D printing still referred only to the polymer technologies in most

minds, and the term AM was likelier to be used in metalworking contexts than among

polymer/inkjet/stereo lithography enthusiasts.

By the early 2010s, the terms 3D printing and additive manufacturing developed senses in which they

were synonymous umbrella terms for all AM technologies. Although this was a departure from their

earlier technically narrower senses, it reflects the simple fact that the technologies all share the

common theme of sequential-layer material addition/joining throughout a 3D work envelope under

automated control. (Other terms that have appeared, which are usually used as AM synonyms have

beendesktop manufacturing, rapid manufacturing [as the logical production- level successor to rapid

prototyping], and on-demand manufacturing [which echoes on-demand printing in the 2D sense of

printing].) The 2010s were the first decade in which metal parts such as engine brackets and large

nutswould be grown (either before or instead of machining) in job production rather than

obligatory being machined from bar stock or plate. The term subtractive has not replaced

the term machining, instead complementing it when a term thatcovers any removal method is needed.](https://image.slidesharecdn.com/1-240422043147-bfcd0900/85/Internship-report-on-mechanical-engineering-204-320.jpg)

![Selective Laser Melting (SLM) does not use sintering for the fusion of powder granules but will

completely melt the powder using a high-energy laser to create fully dense materials in a layer- wise

method that has mechanical properties similar to those of conventional manufacturedmetals.

Electron beam melting (EBM) is a similar type of additive manufacturing technology for metal parts

(e.g. titanium alloys). EBM manufactures parts by melting metal powder layer by layer with an

electron beam in a high vacuum. Unlike metal sintering techniques that operate below melting point,

EBM parts are fully dense, void-free, and very strong.

Another method consists of an inkjet 3D printing system. The printer creates the model one layerat a

time by spreading a layer of powder (plaster, or resins) and printing a binder in the cross- section of

the part using an inkjet-like process. This is repeated until every layer has been printed. This

technology allows the printing of full color prototypes, overhangs, and elastomer parts. The strength

of bonded powder prints can be enhanced with wax or thermoset polymer impregnation.

Lamination

In some printers, paper can be used as the build material, resulting in a lower cost to print. During

the 1990s some companies marketed printers that cut cross sections out of special adhesive coated

paper using a carbon dioxide laser and then laminated them together.

In 2005, Mcor Technologies Ltd developed a different process using ordinary sheets of office paper,

a Tungsten carbide blade to cut the shape, and selective deposition of adhesive and pressure to bond

the prototype.[36]

There are also a number of companies selling printers that print laminated objects using thin plastic

and metal sheets

Photo polymerization

Stereo lithography was patented in 1986 by Chuck Hull. Photo polymerization is primarily used in

stereo lithography (SLA) to produce a solid part from a liquid. This process dramatically redefined

previous efforts, from the photosculpture method of François Willème (1830–1905) in 1860

through the photopolymerization of Mitsubishi's Matsubara in 1974. The photosculpture method

consisted of photographing a subject from a variety of equidistant angles and projecting each

photograph onto a screen, where a pantagraph was used to trace the outline onto modeling clay)](https://image.slidesharecdn.com/1-240422043147-bfcd0900/85/Internship-report-on-mechanical-engineering-212-320.jpg)