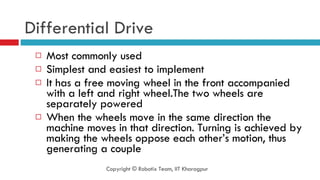

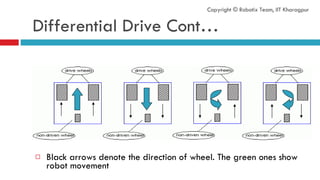

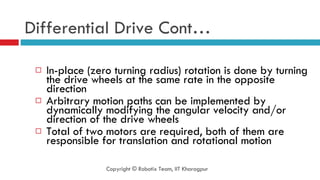

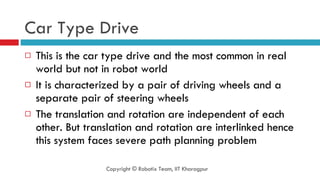

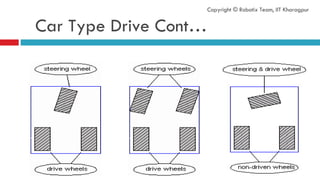

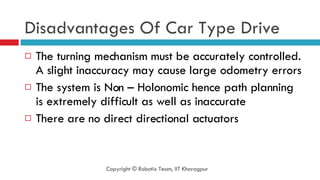

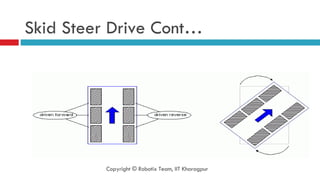

1. The document discusses different types of locomotion systems for mobile robots, including differential drive, car type drive, and skid steer drive.

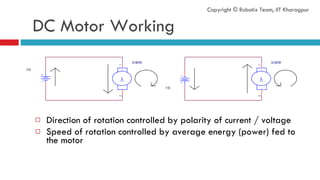

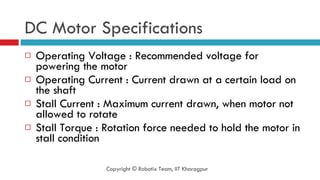

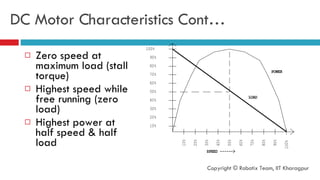

2. It also covers actuators that convert electrical energy to mechanical motion, specifically DC motors which can be controlled to run in different directions and speeds.

3. Sensors that provide feedback are also mentioned as an important component for mobile robots.