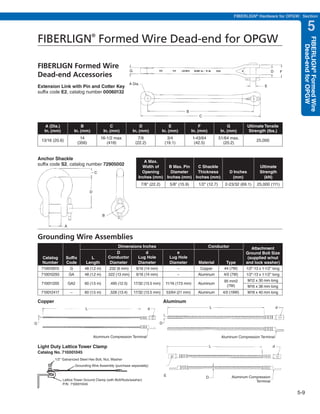

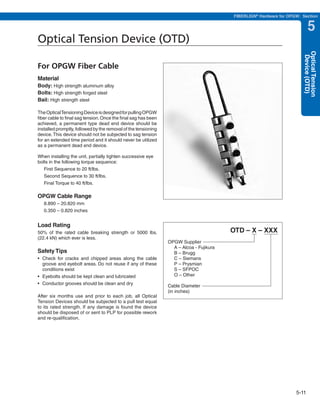

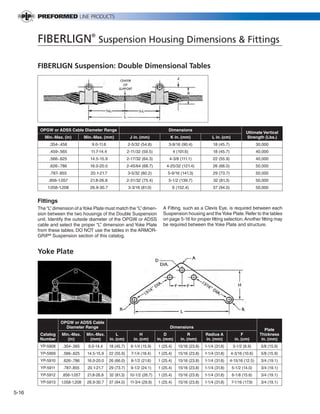

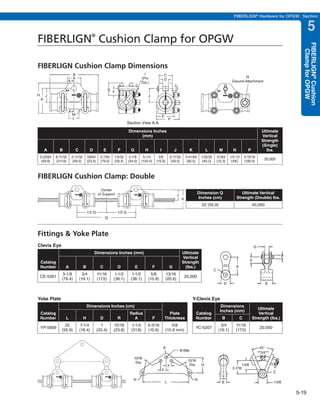

This document section describes PLP's FIBERLIGN hardware products for OPGW (Optical Ground Wire), including dead-ends, formed wire dead-ends, ground clamps, optical tension devices, suspensions, cushion clamps, and repair rods. It provides details on the components, applications, and ordering instructions for the FIBERLIGN Dead-end for OPGW, which utilizes retaining rods, wedges, a housing and U-bolt to distribute loading over the OPGW while minimizing compression stresses on the optical elements. Dimensions, strengths, and acceptable fittings are specified.