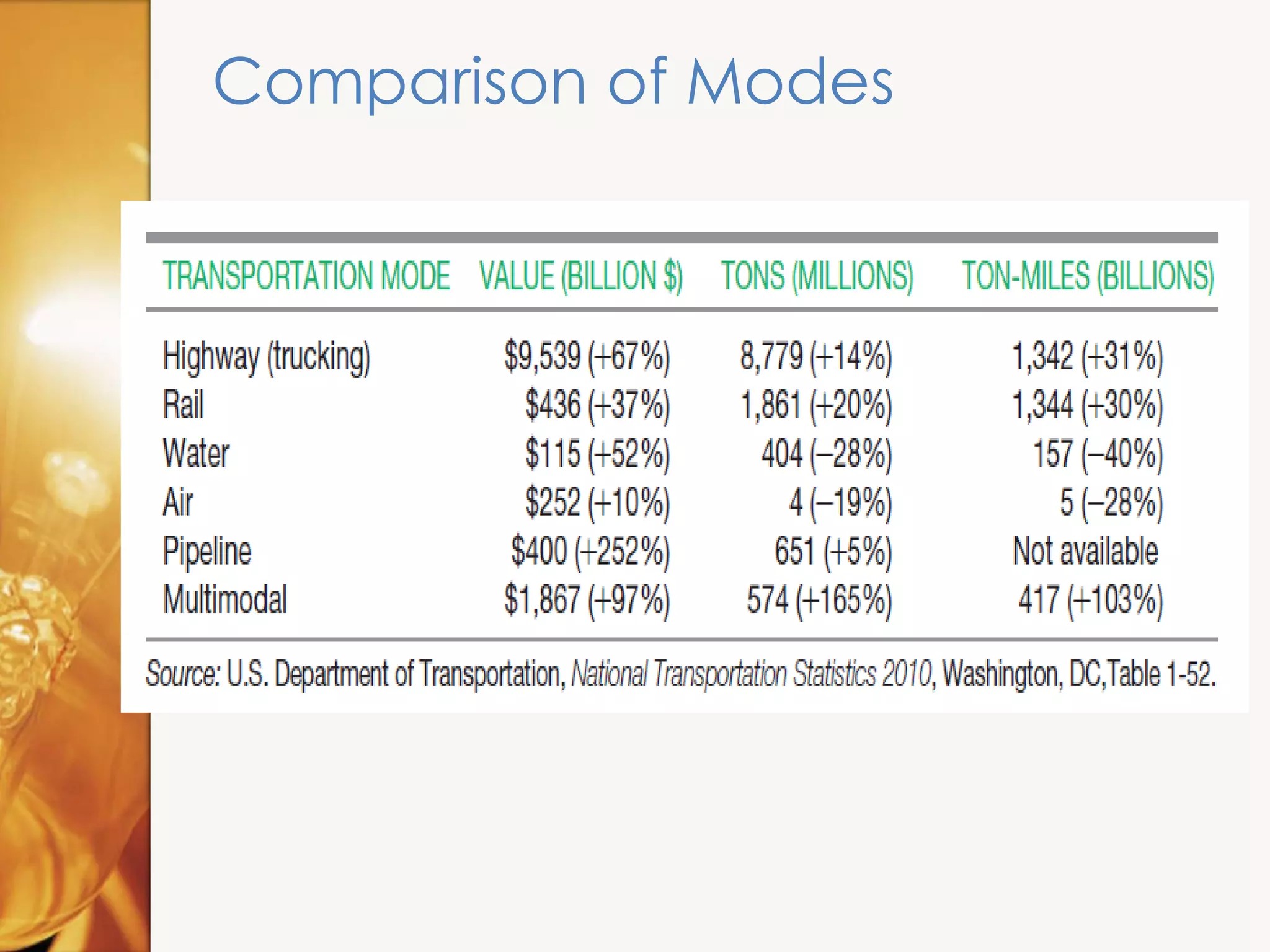

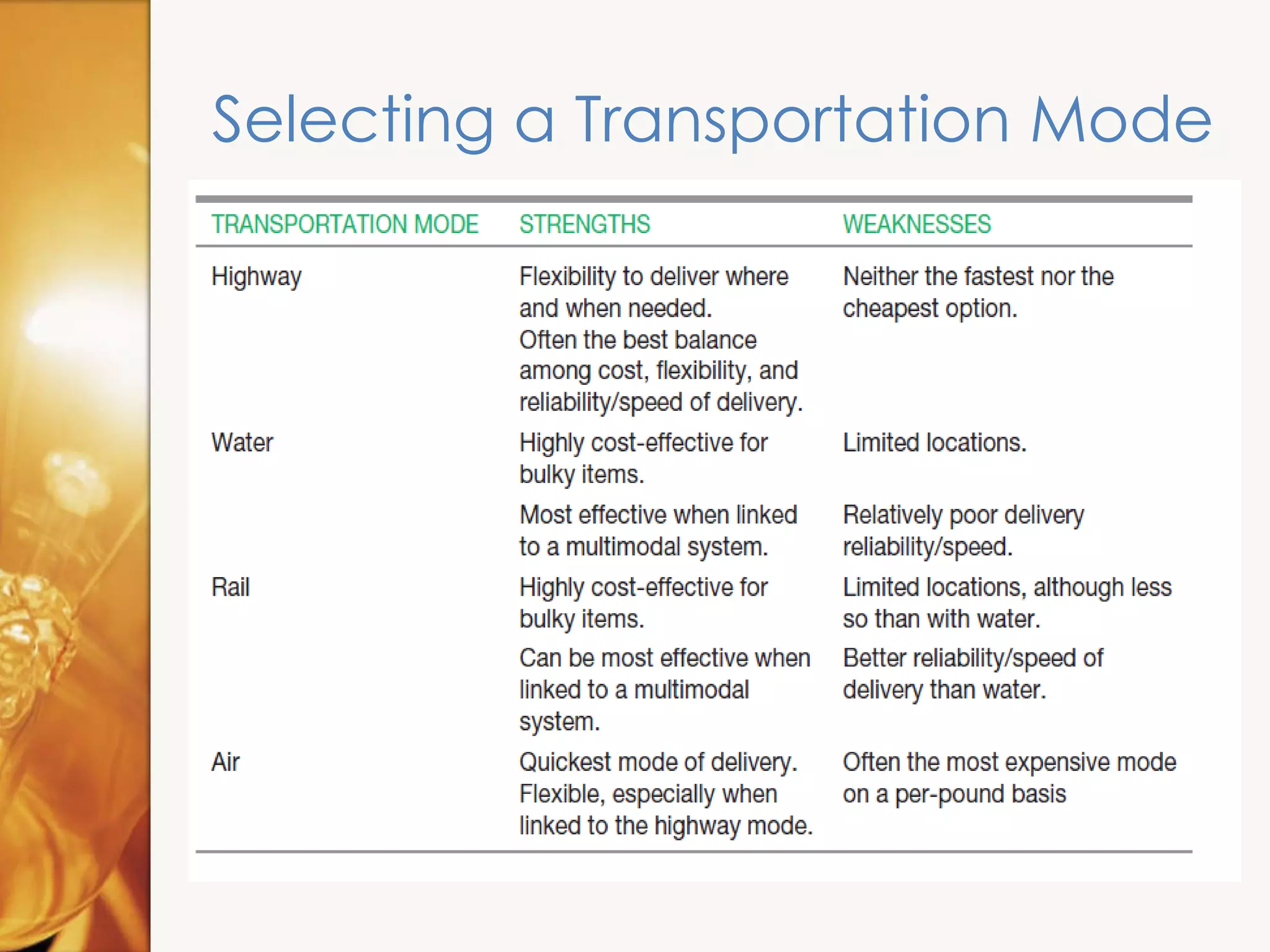

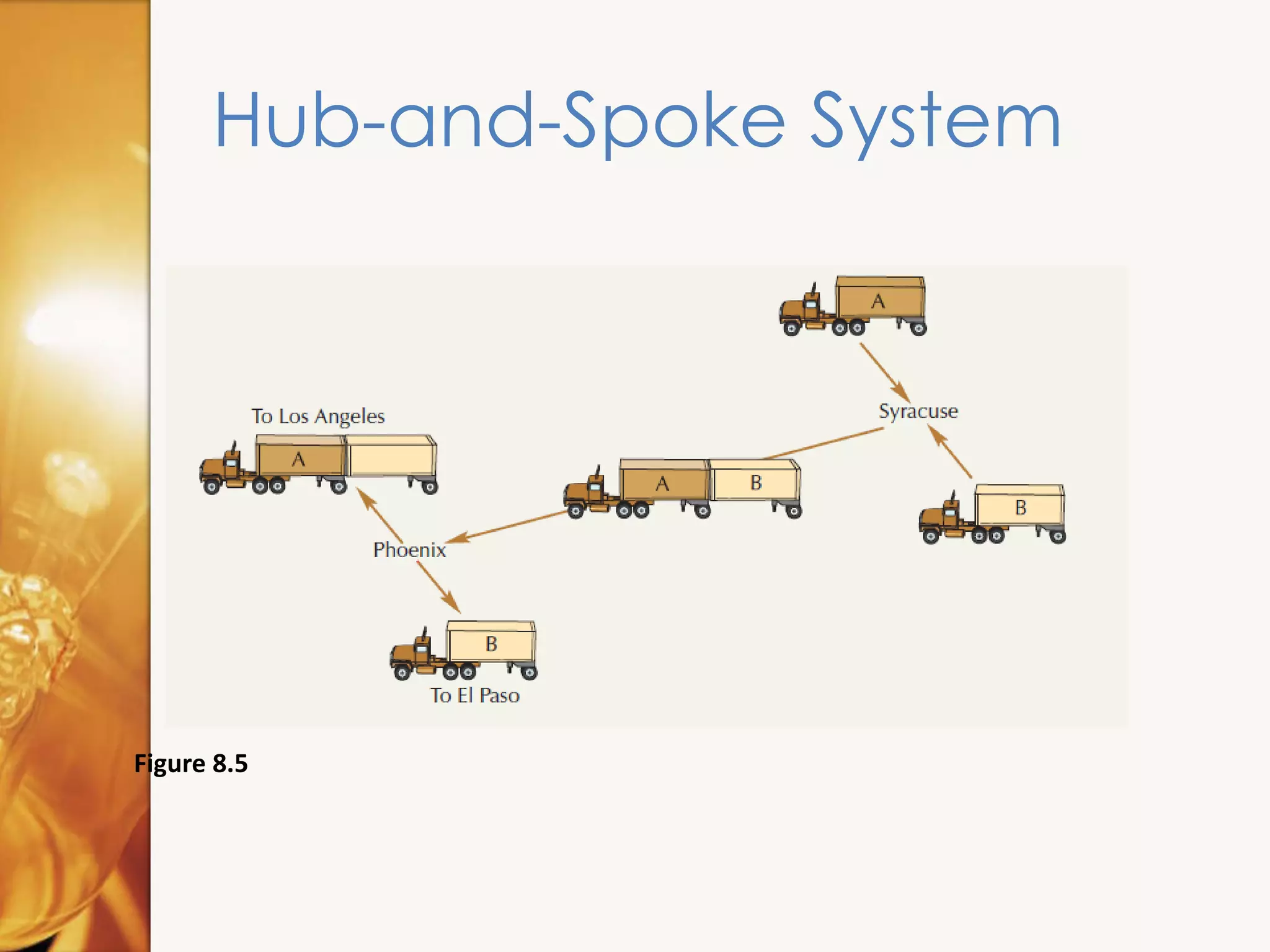

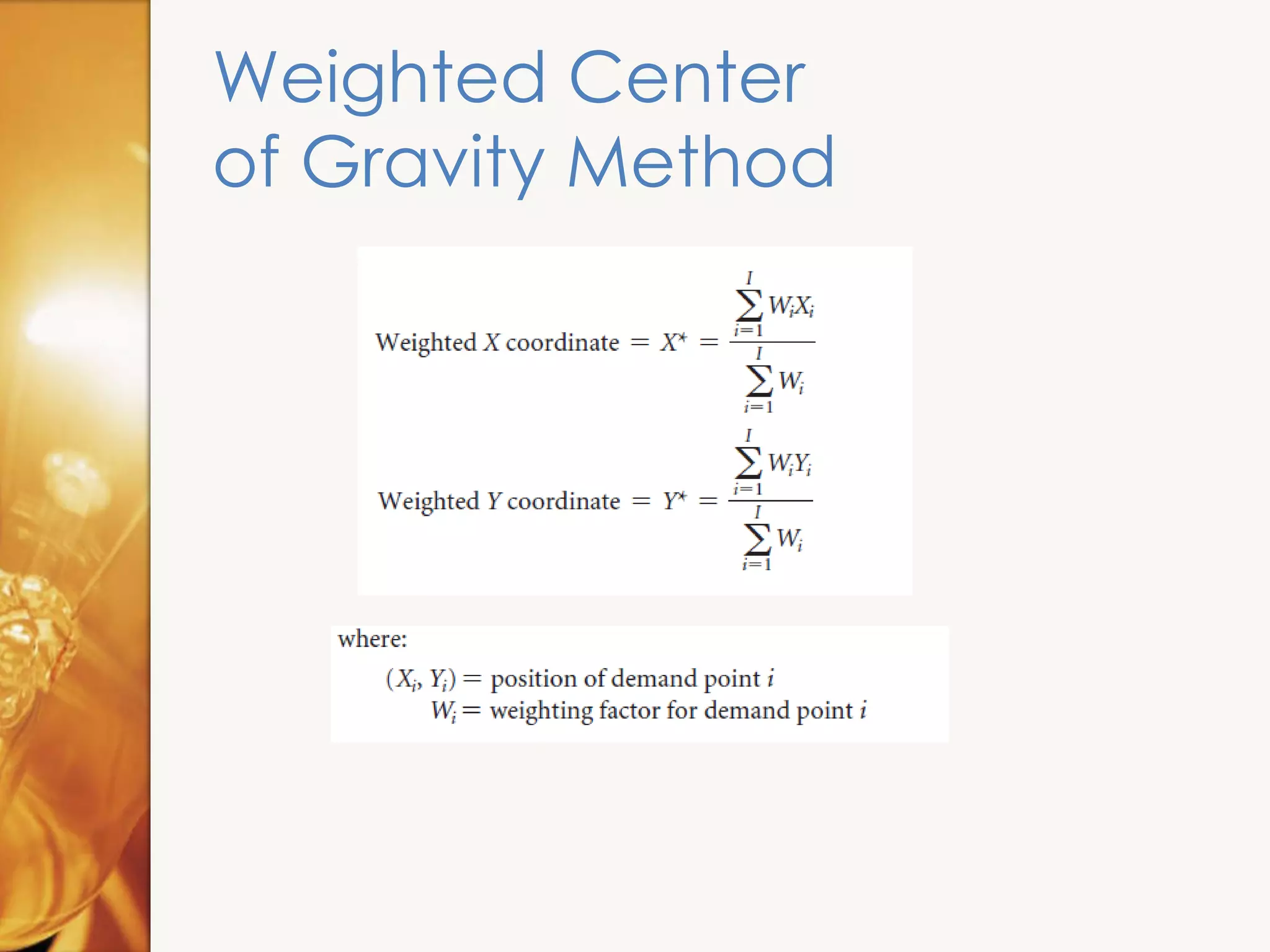

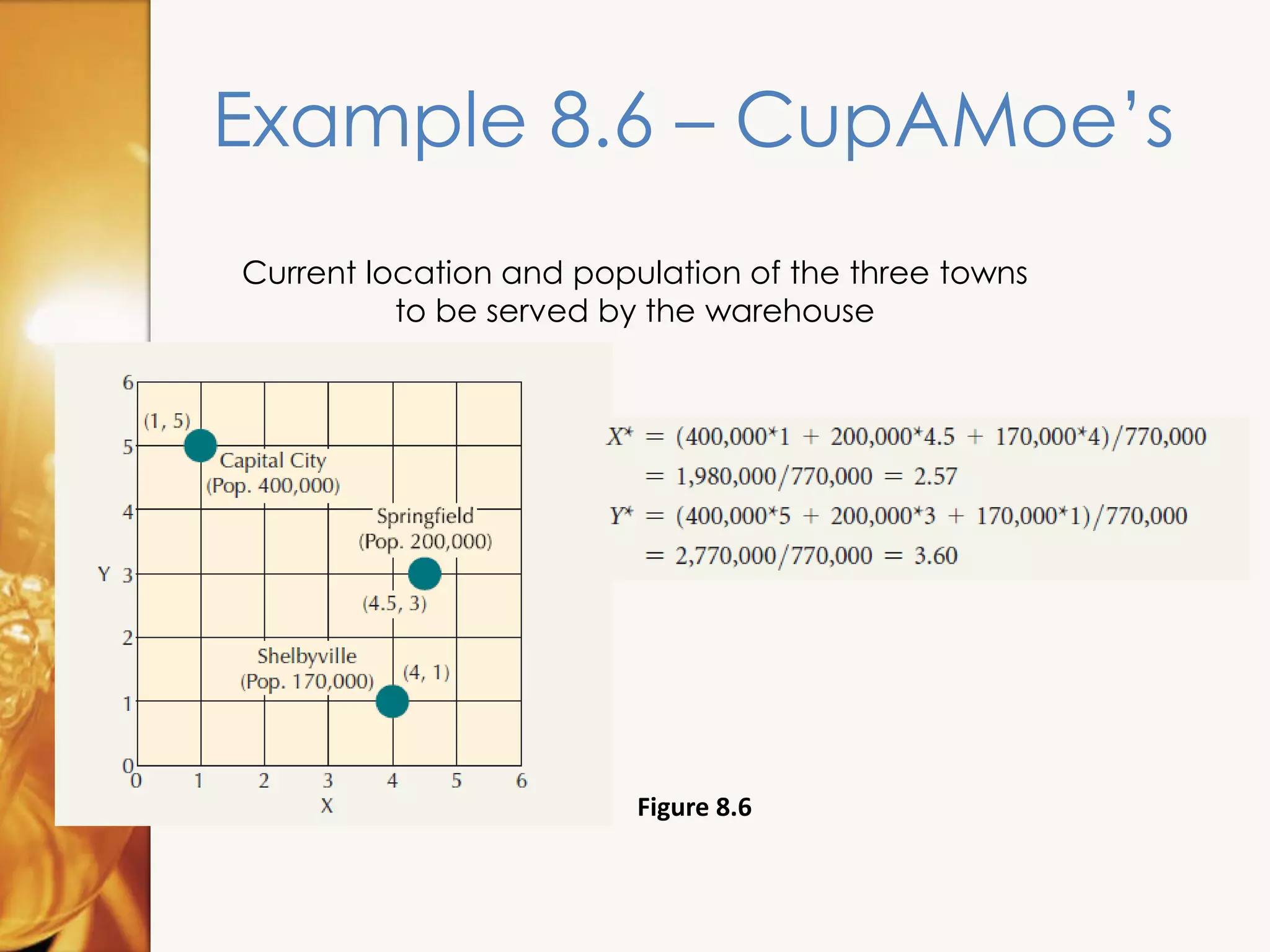

The document provides an overview of key concepts in logistics management. It discusses the importance of logistics and major decision areas. These include transportation methods, warehousing types, inventory management, and logistics information systems. The document also covers topics like reverse logistics, location analysis methods, and optimization modeling. The overall goal is to describe how logistics supports business strategy and discuss approaches for important logistics decisions.