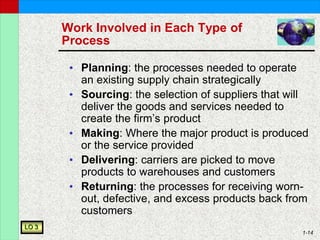

Logistics plays a strategic role in coordinating purchasing, distribution, and other functions to deliver goods and services. The document outlines key logistics activities like planning, sourcing, production, delivery, and returns. It provides examples of how these processes work for a transit bus operation and IKEA's supply chain. The different modes of transportation like truck, ship, air, rail, pipeline, and hand delivery are also discussed.