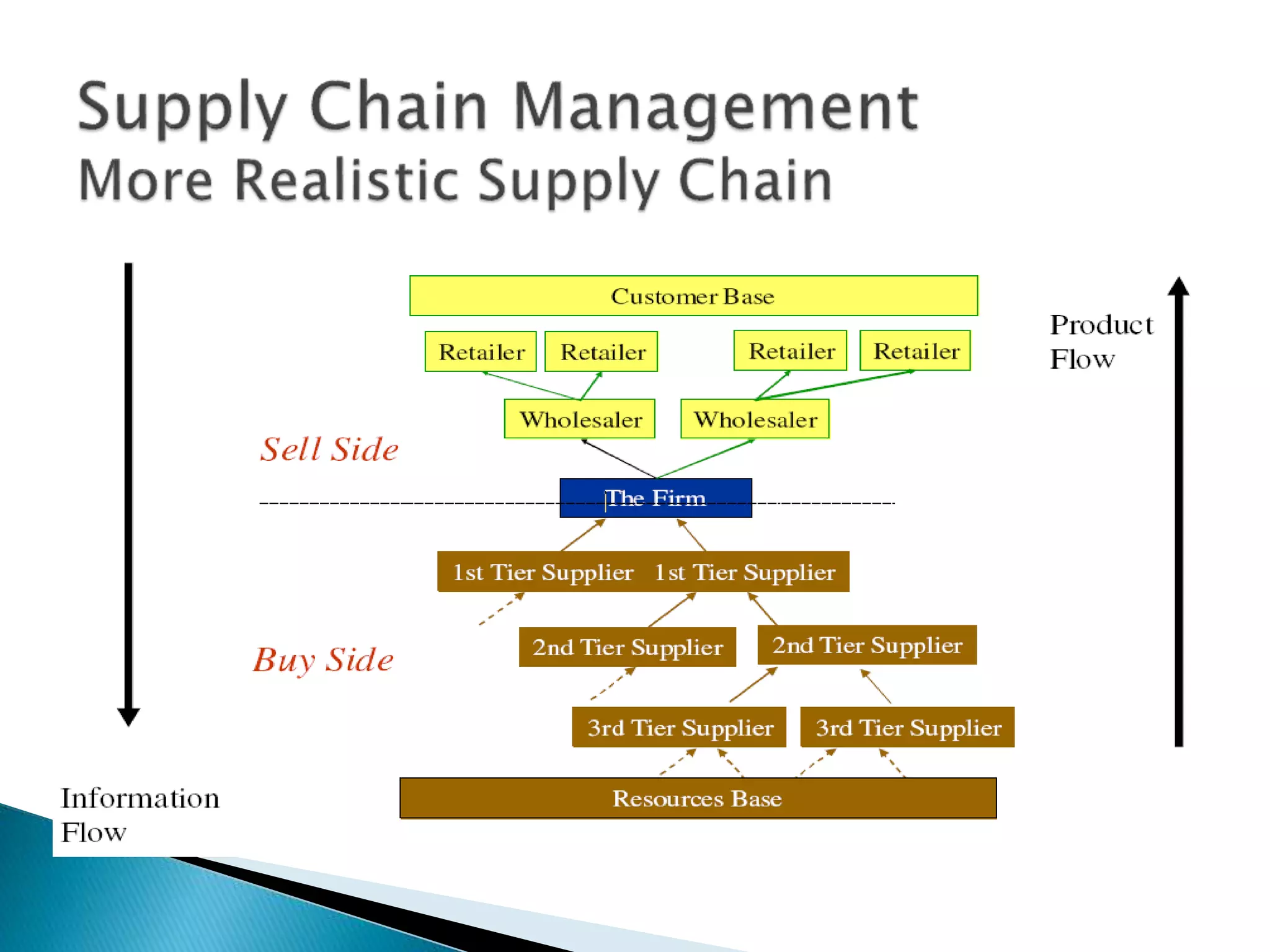

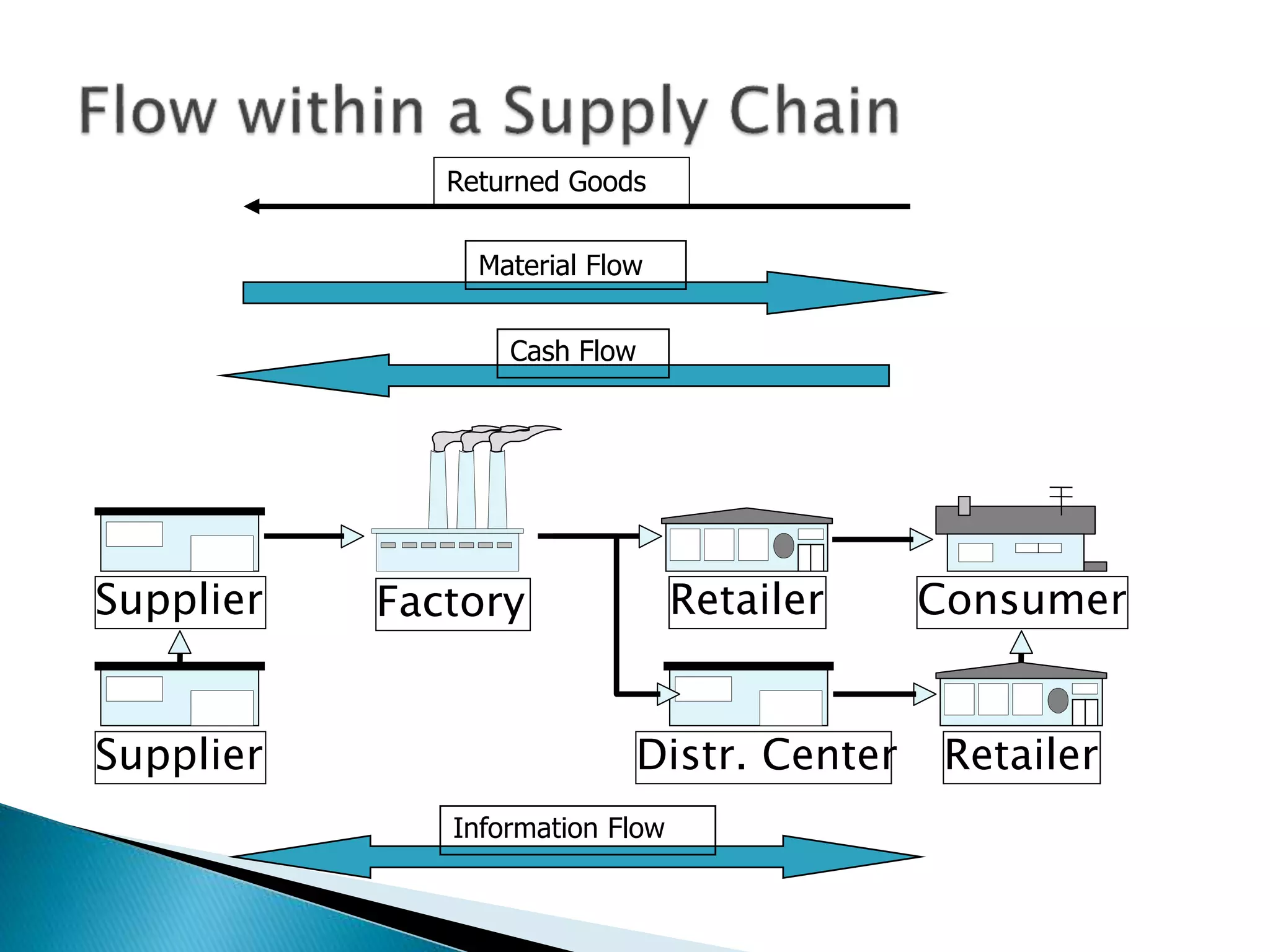

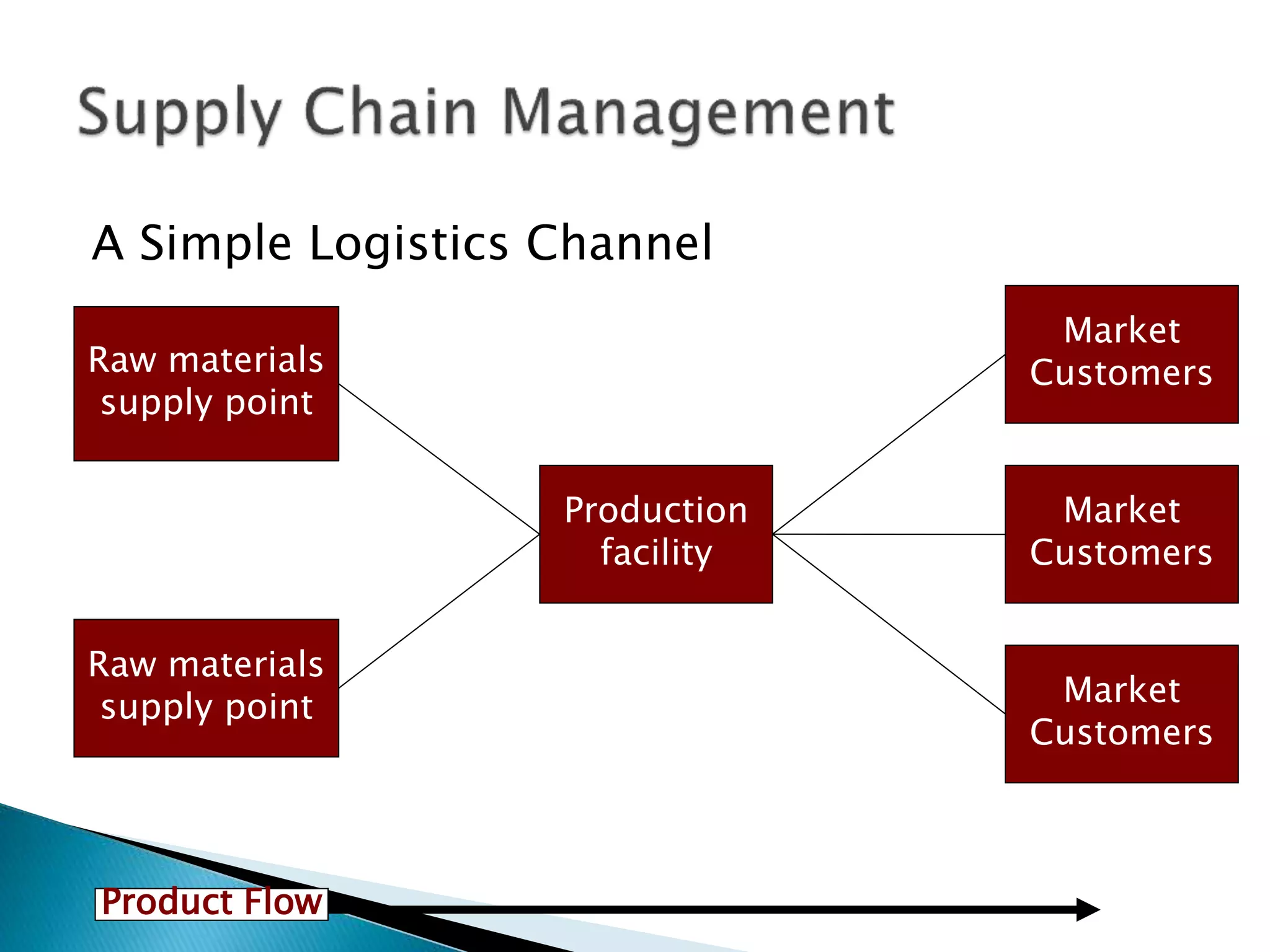

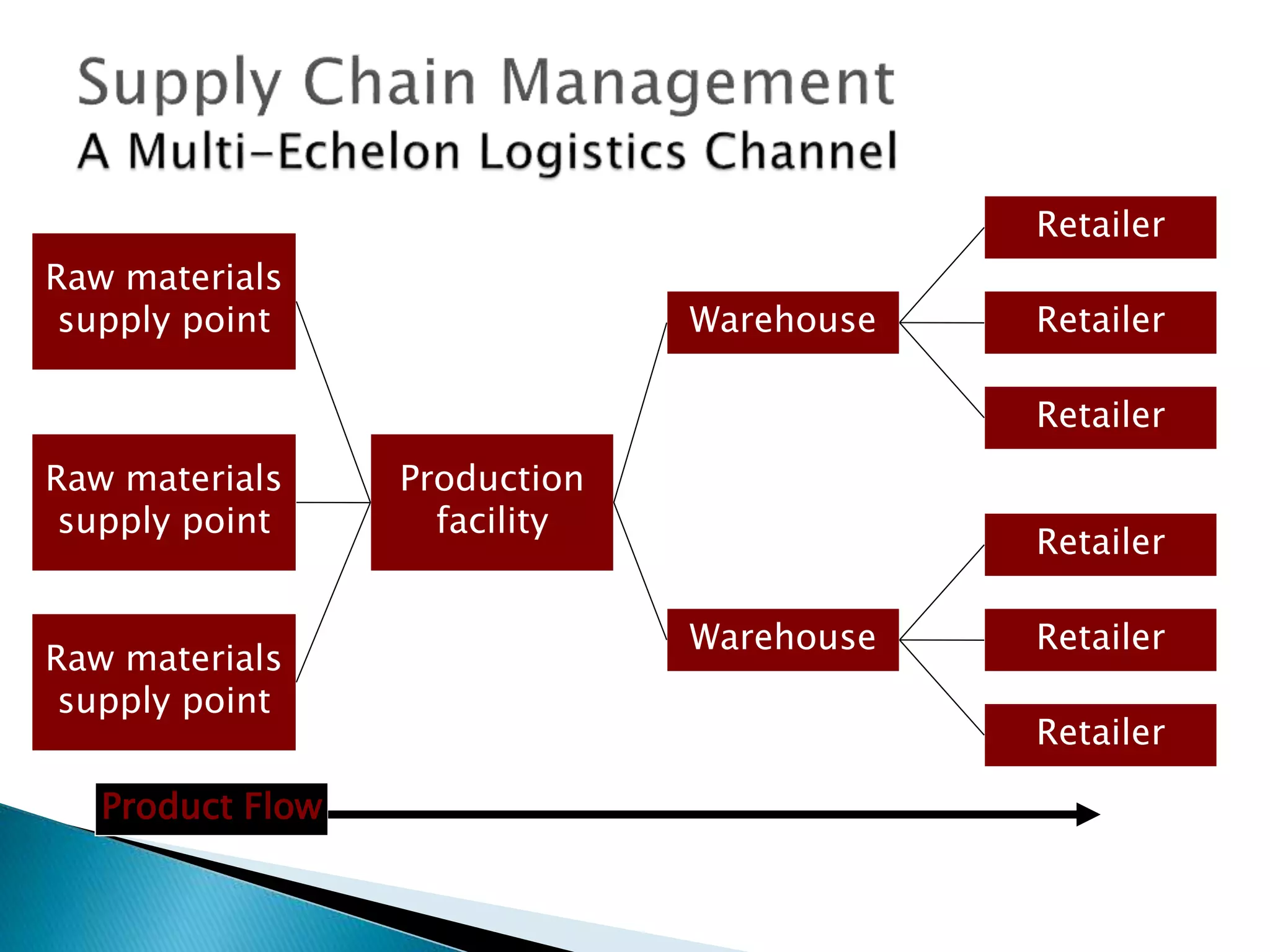

Supply chain management involves coordinating the flow of goods and services from suppliers to customers. The goal is to satisfy customer needs with minimum costs and delays. Key aspects of supply chain management include purchasing, manufacturing, warehousing, inventory management, and logistics. Coordinating these complex activities across different entities is challenging due to conflicting objectives. Overall integration and information sharing across the supply chain are important to improve efficiency and reduce costs.