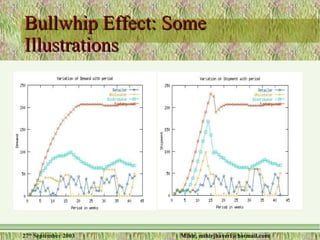

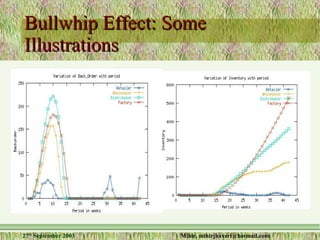

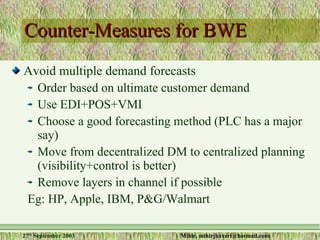

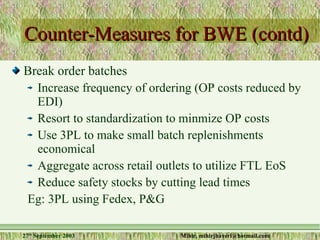

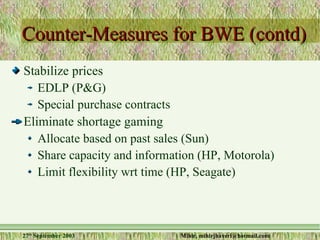

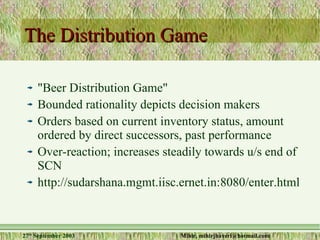

The document discusses key concepts in supply chain management including product postponement, collaboration and coordination, controlling inventories, hierarchical production planning, and the bullwhip effect. It summarizes Forrester's 1958 research which first illustrated the bullwhip effect - how demand fluctuations can amplify as orders move up the supply chain resembling a whip lash. The causes of the bullwhip effect are discussed as well as countermeasures that can be taken.