This document discusses production scheduling concepts including loading, sequencing, and scheduling. It provides examples and explanations of:

- Loading assigns work to facilities like departments and machines. The objectives are to minimize waiting and congestion.

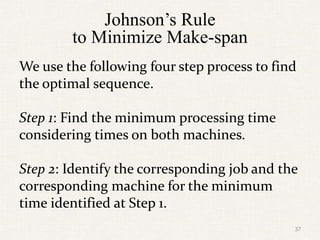

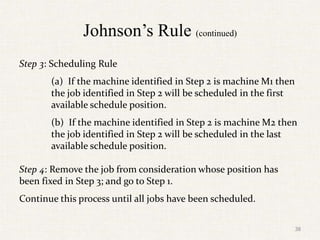

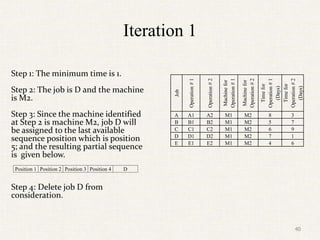

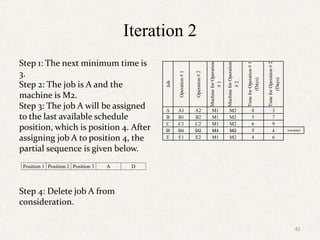

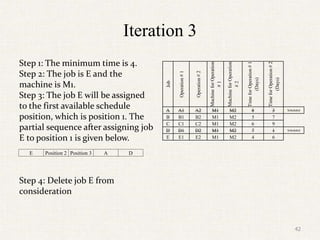

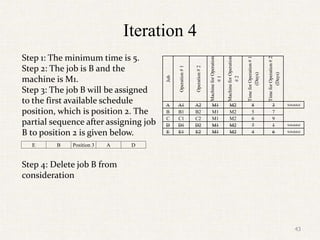

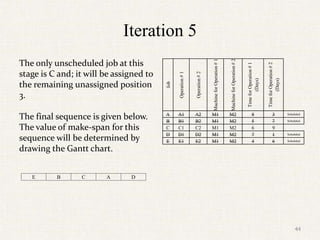

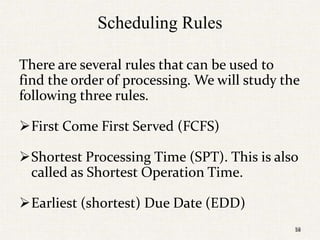

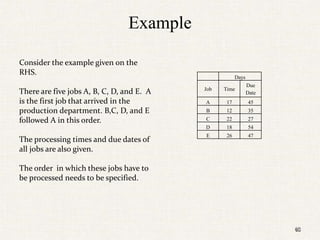

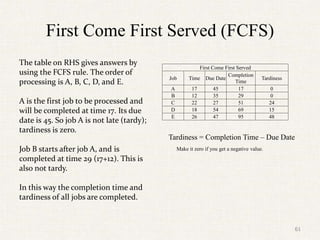

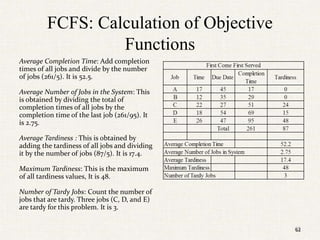

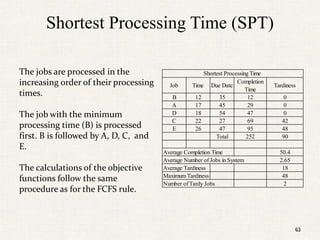

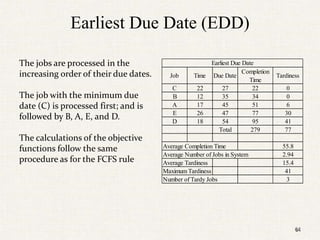

- Sequencing establishes the processing order of jobs at each facility based on priorities. The goal is to minimize costs from waiting and delays.

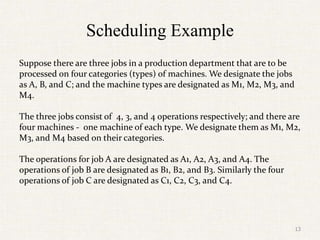

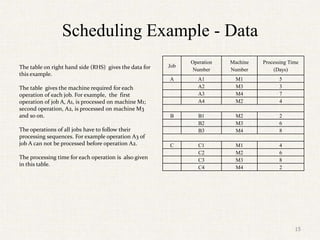

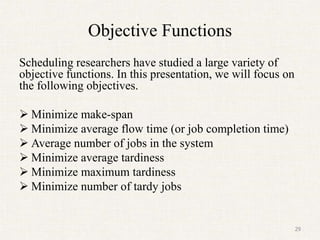

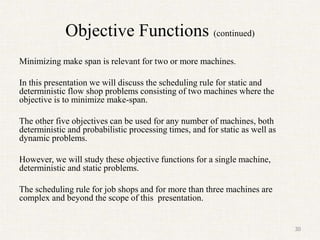

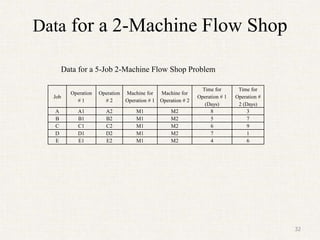

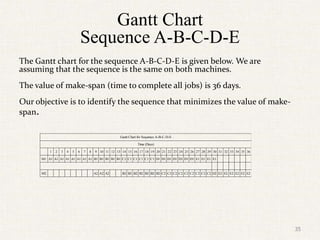

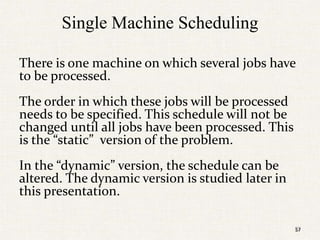

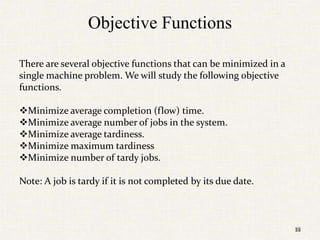

- Scheduling provides start and end times for each job operation on machines. It aims to optimize objectives like minimizing completion time.

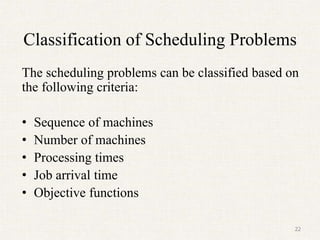

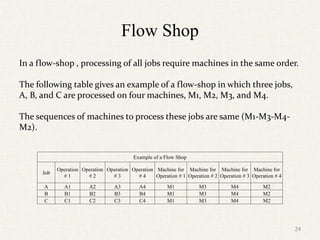

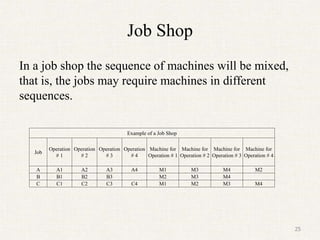

The document also covers classification of scheduling problems by factors like machine sequence, number of machines, processing times, and objectives.