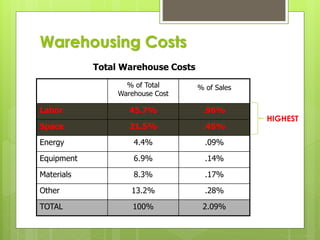

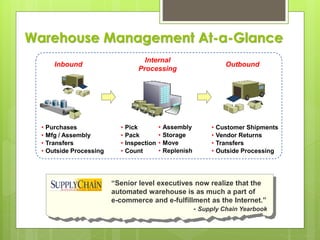

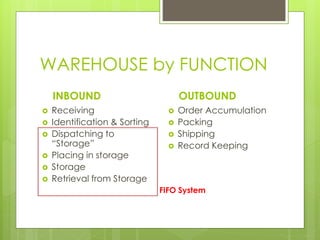

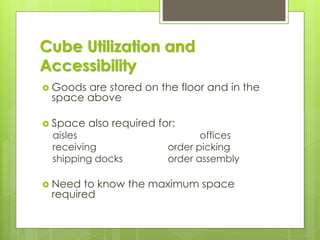

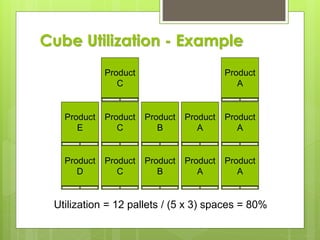

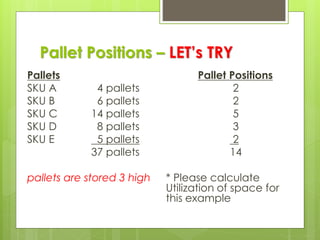

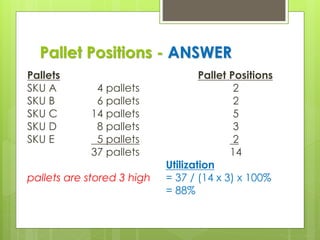

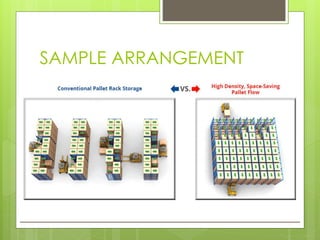

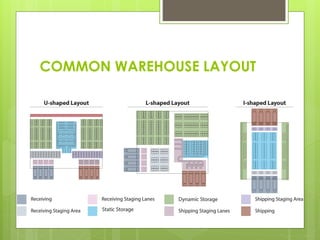

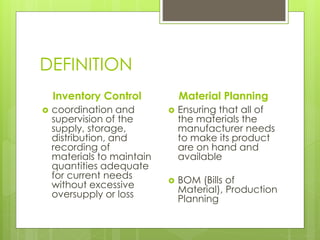

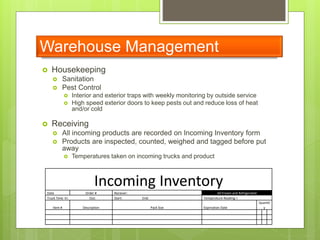

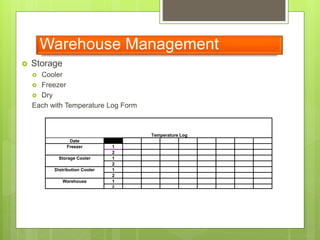

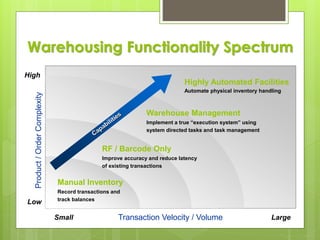

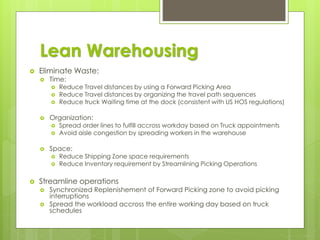

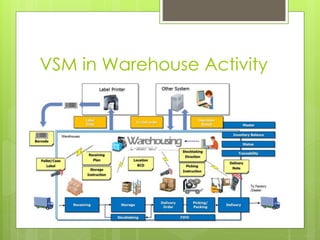

This document provides an overview of warehouse management. It discusses how warehouses are used to store inventory for periods of time and aid in distribution. It also outlines the major costs associated with warehouse operations. The document then explains key warehouse functions like receiving, storage, order picking, and shipping. It discusses important considerations for warehouse management including stock location, order picking methods, and optimizing space utilization.