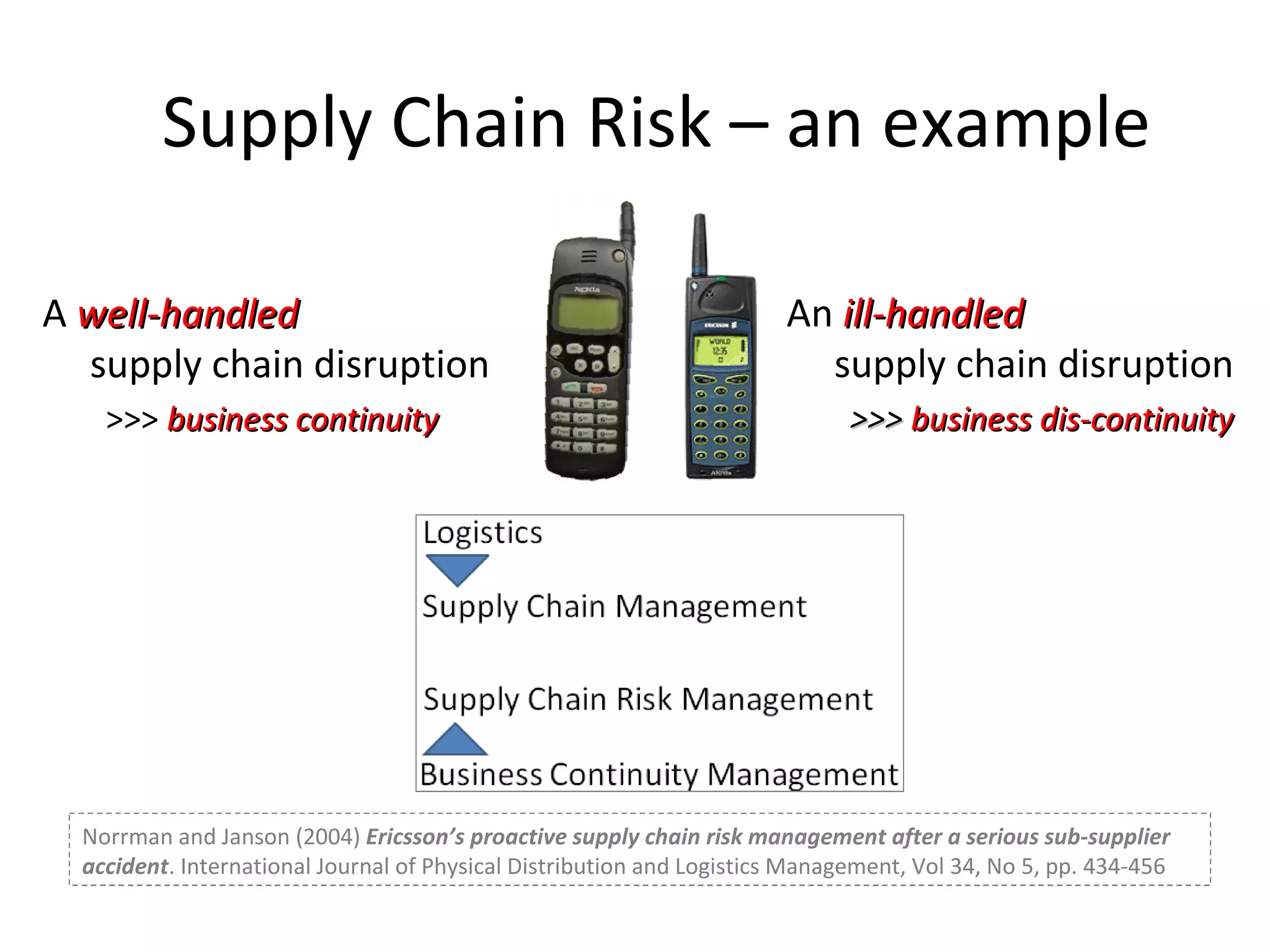

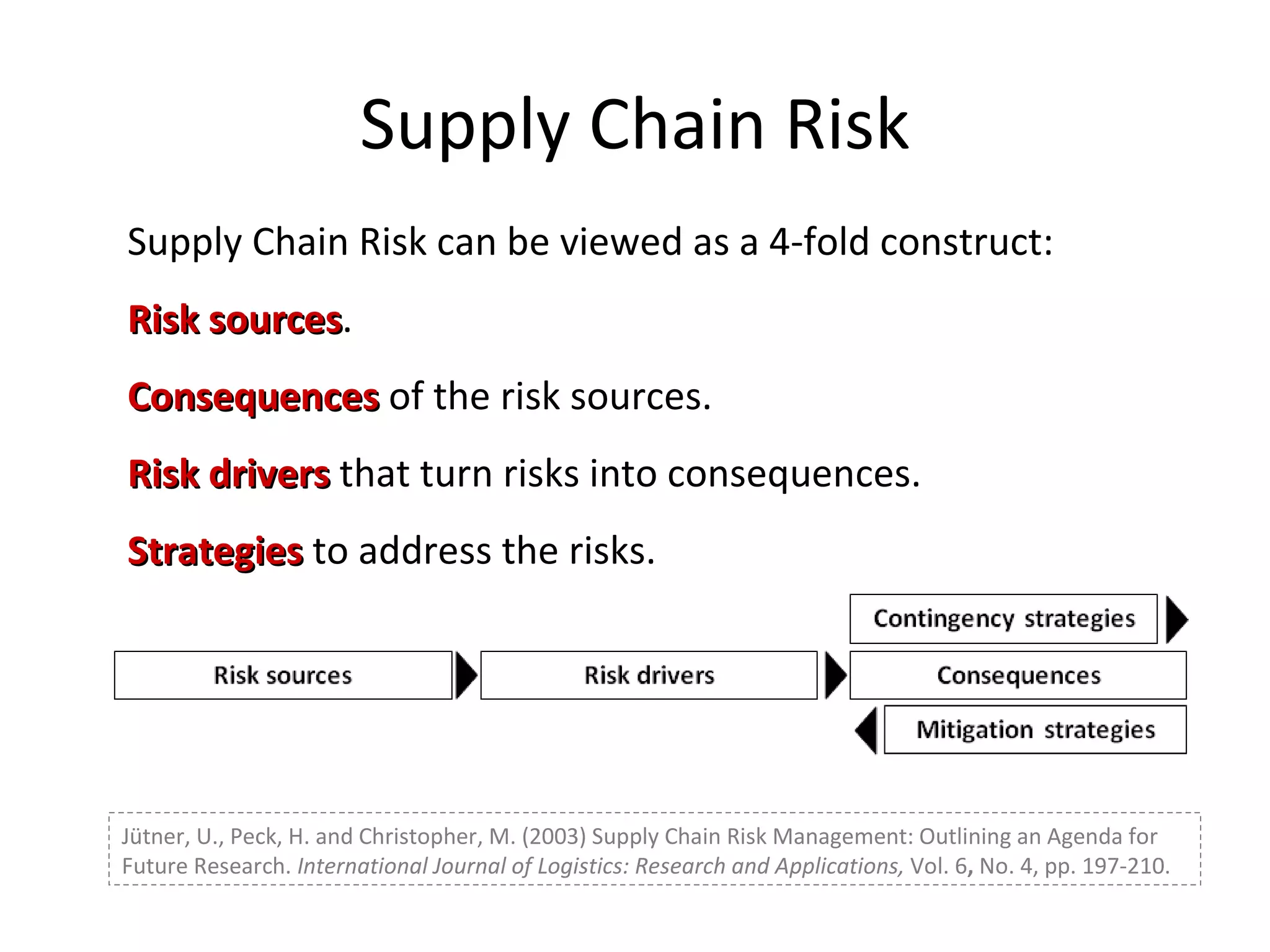

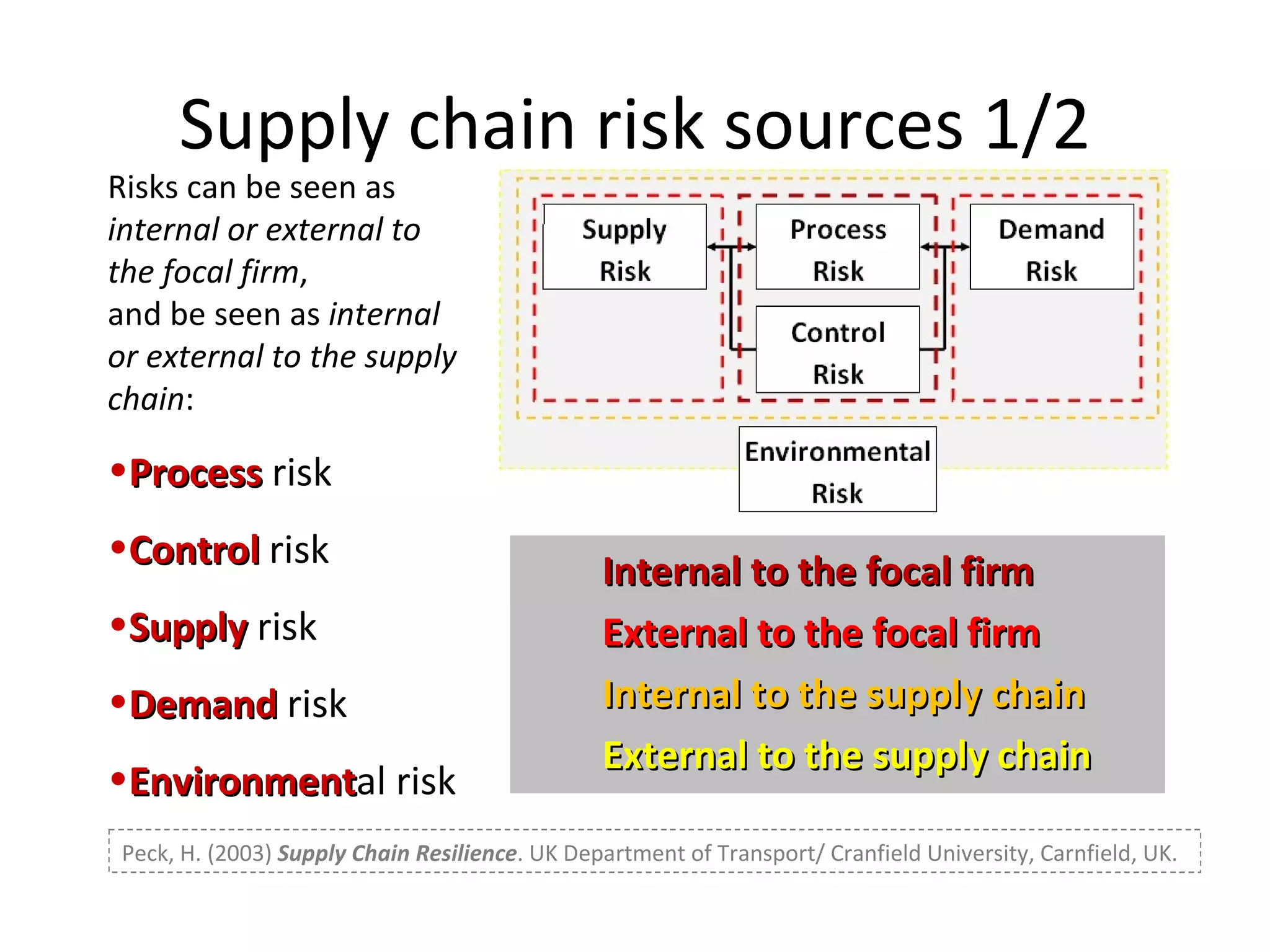

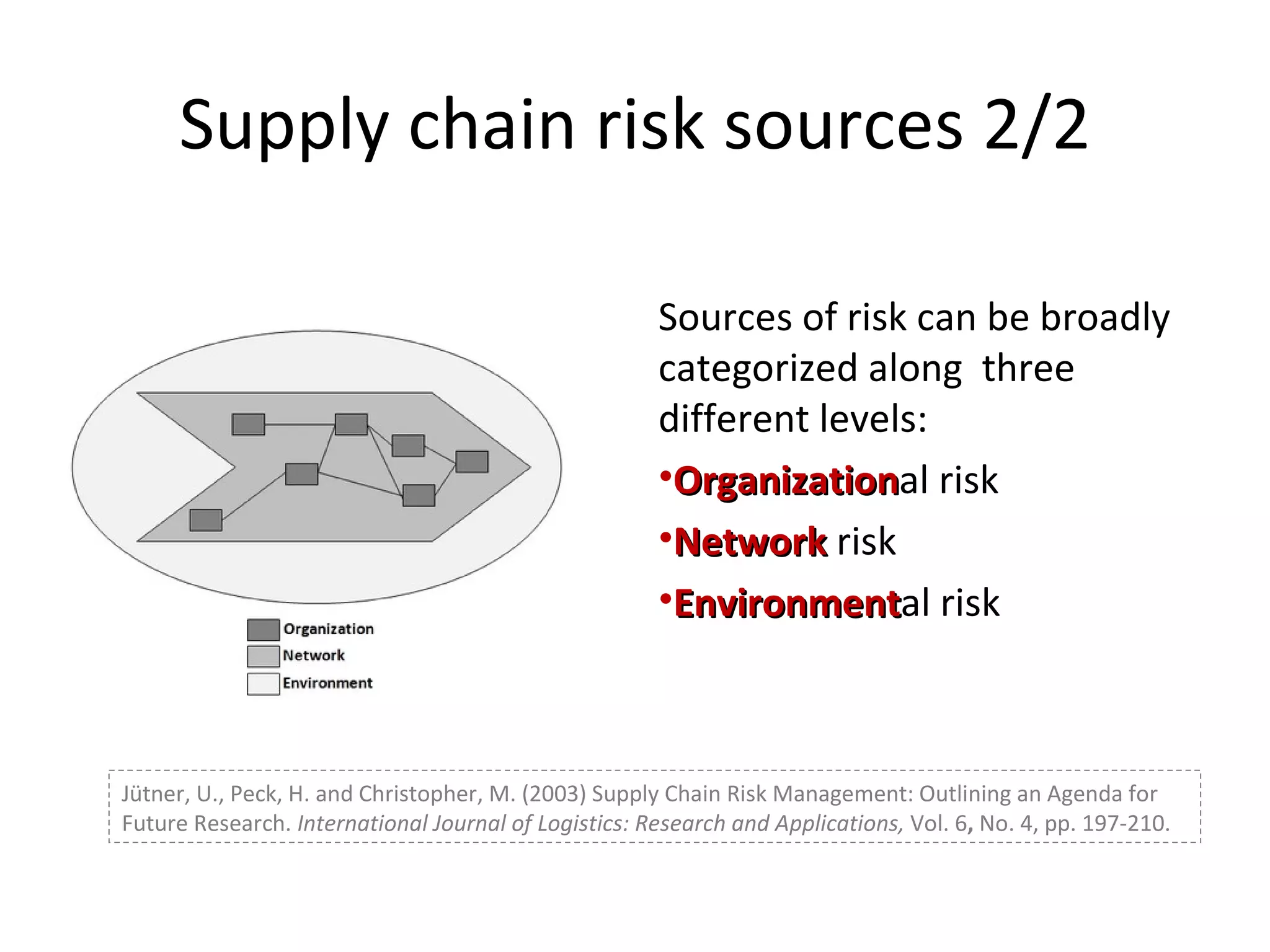

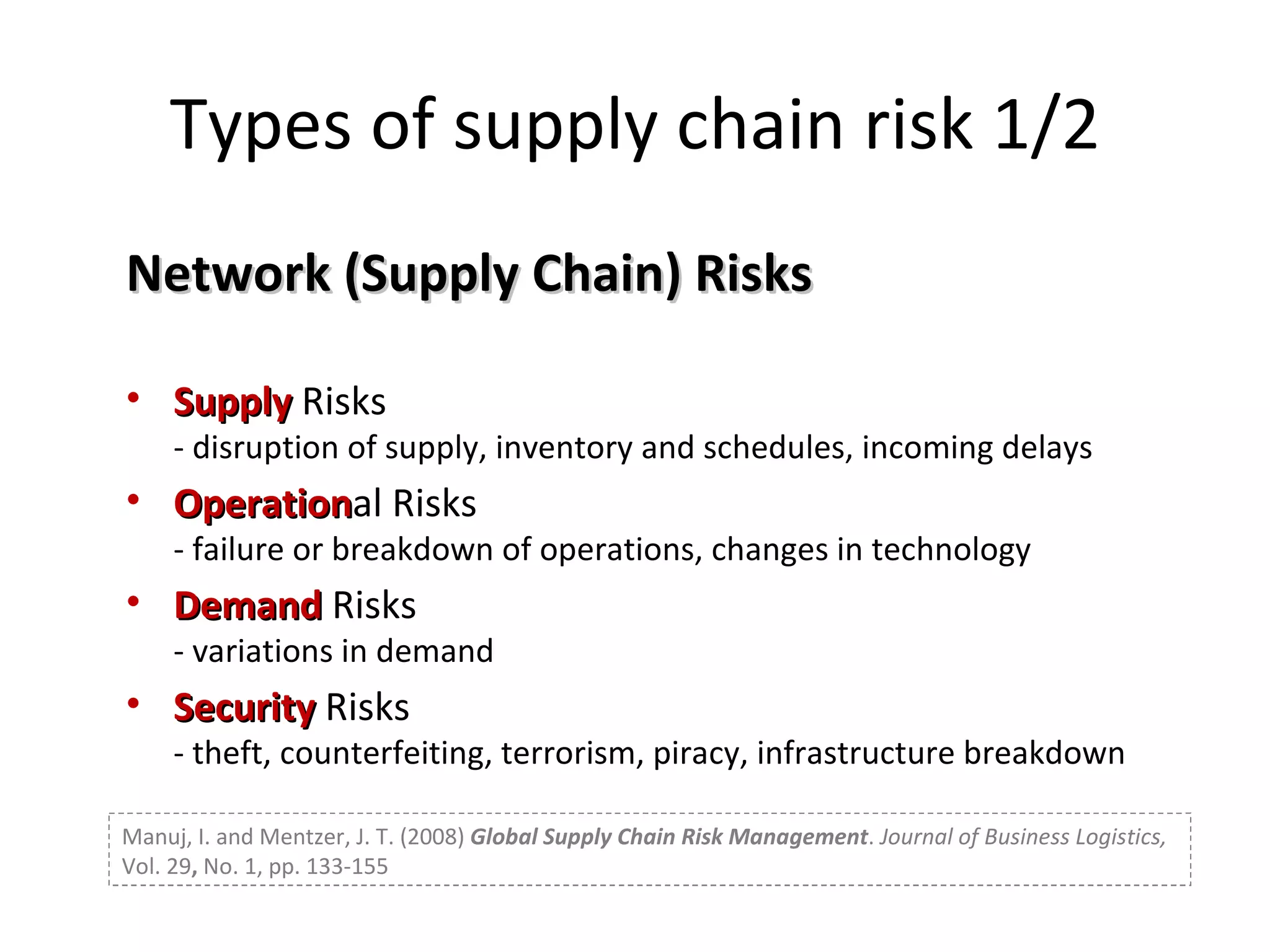

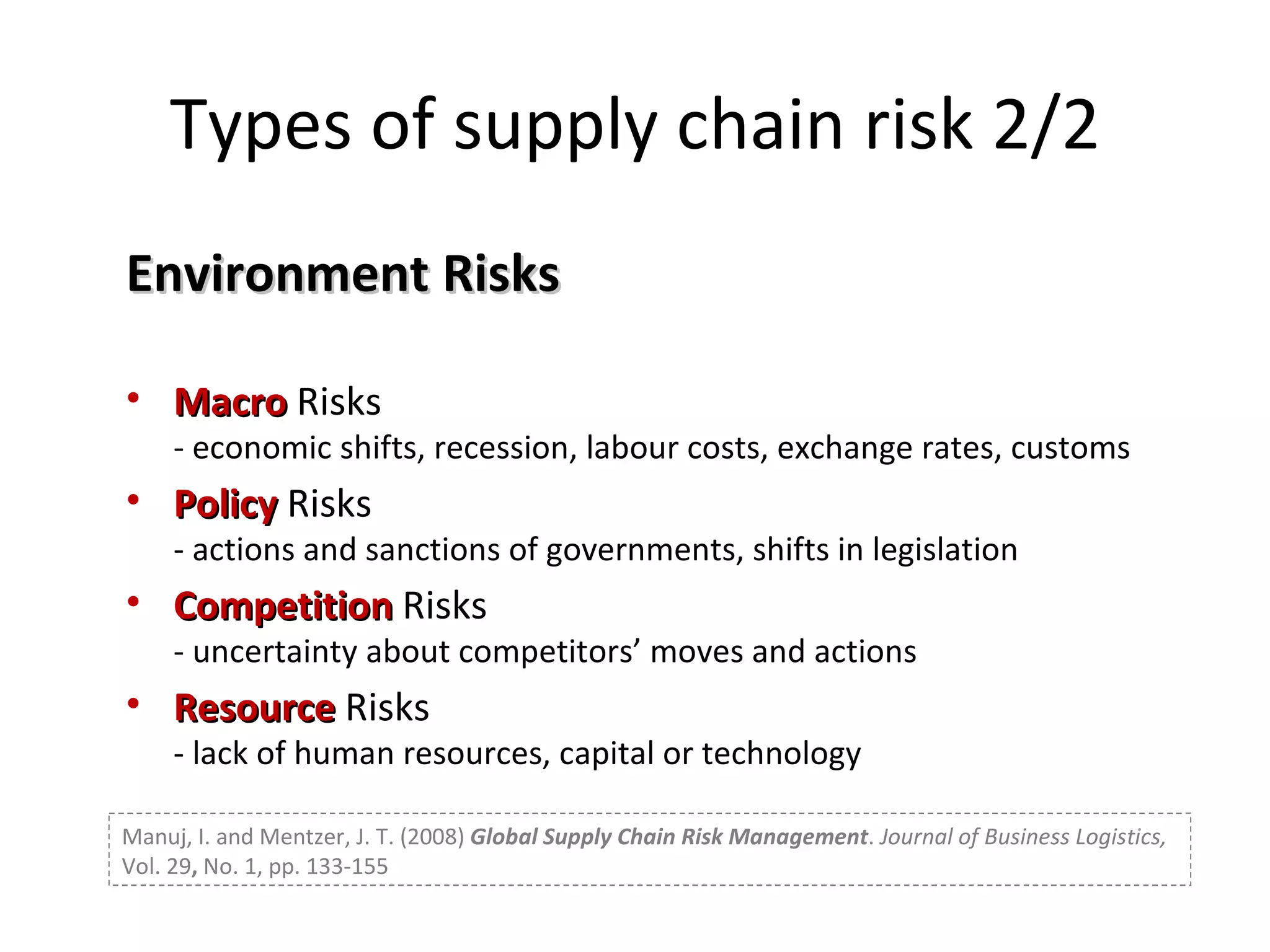

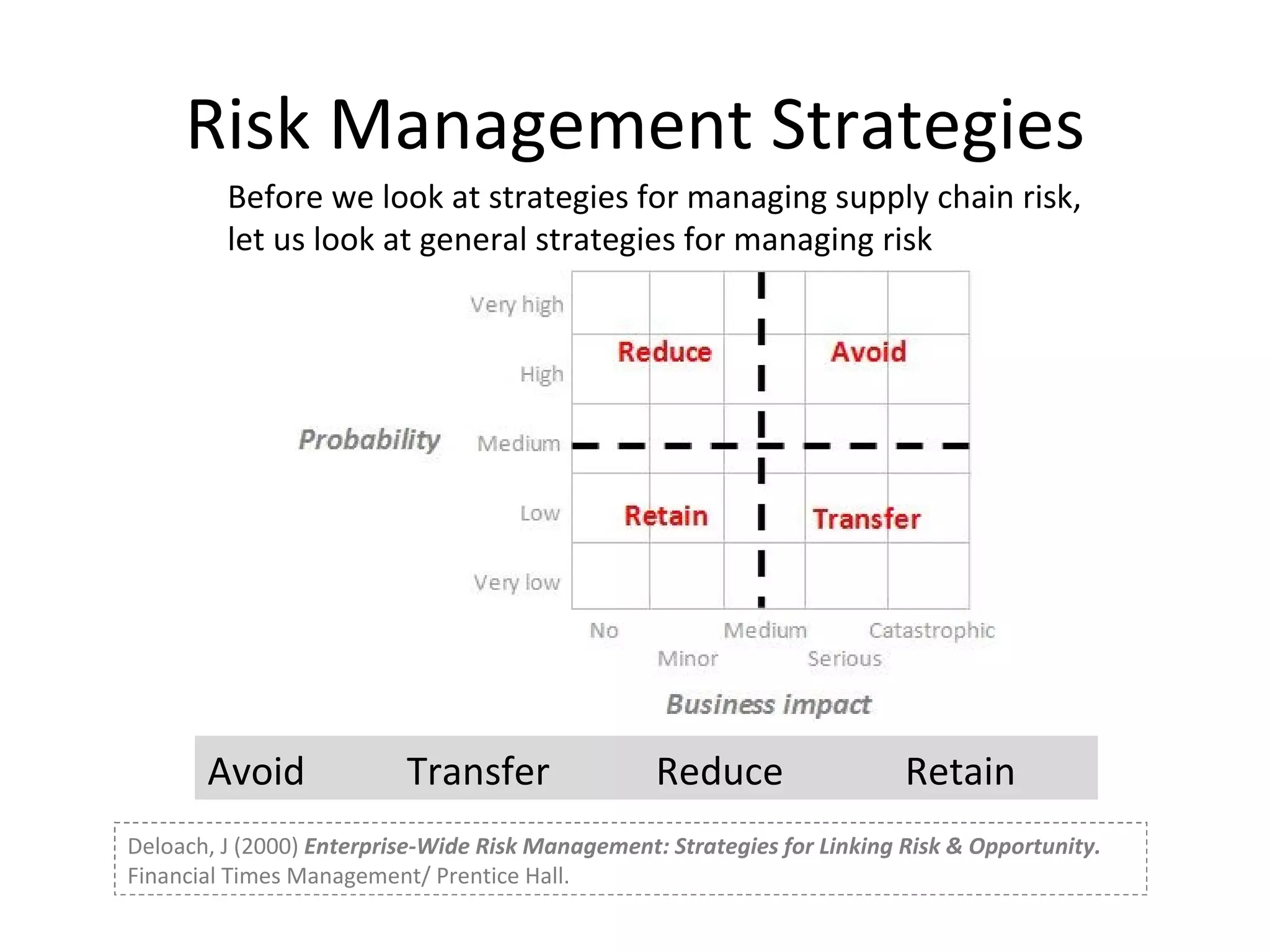

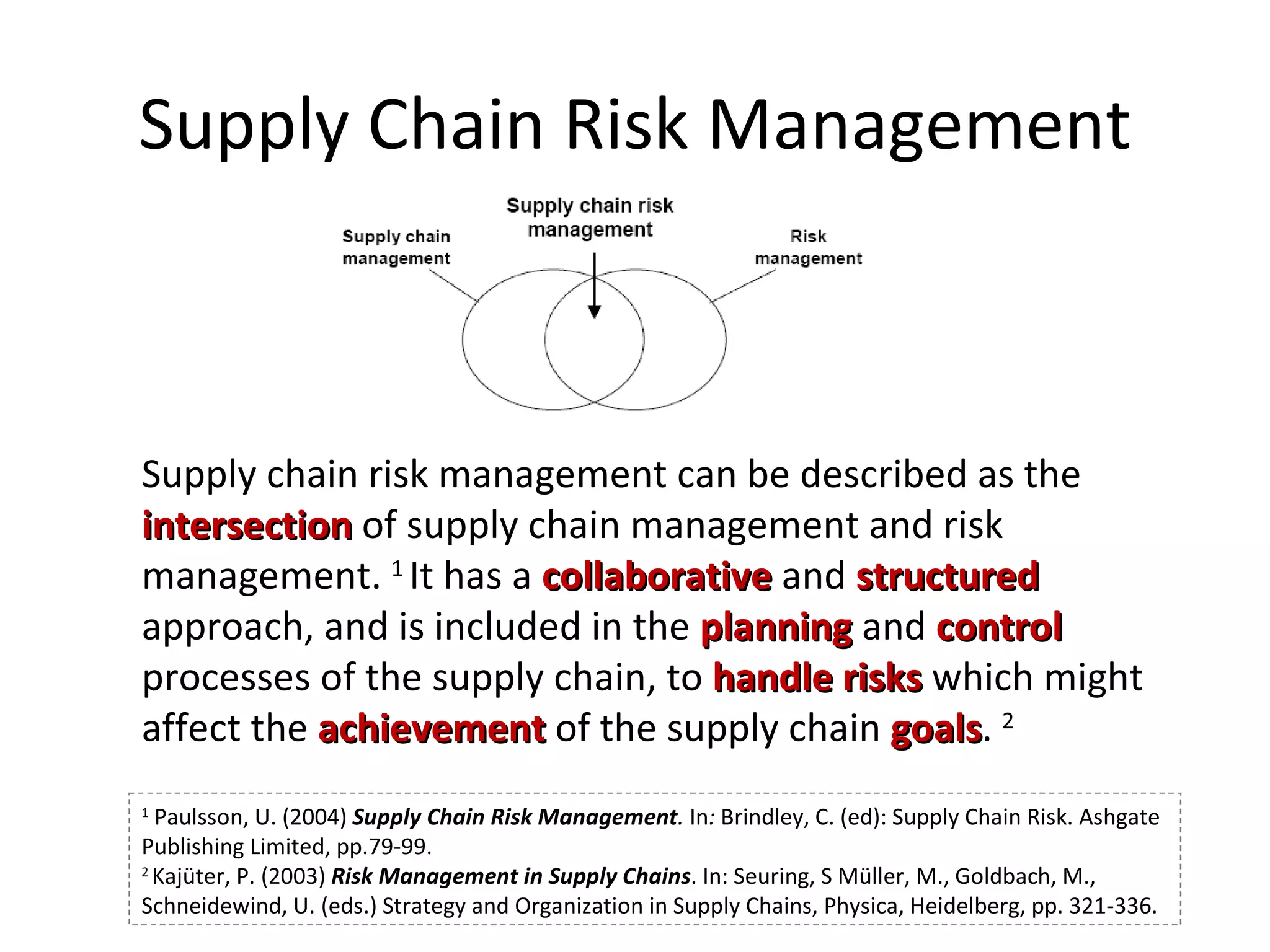

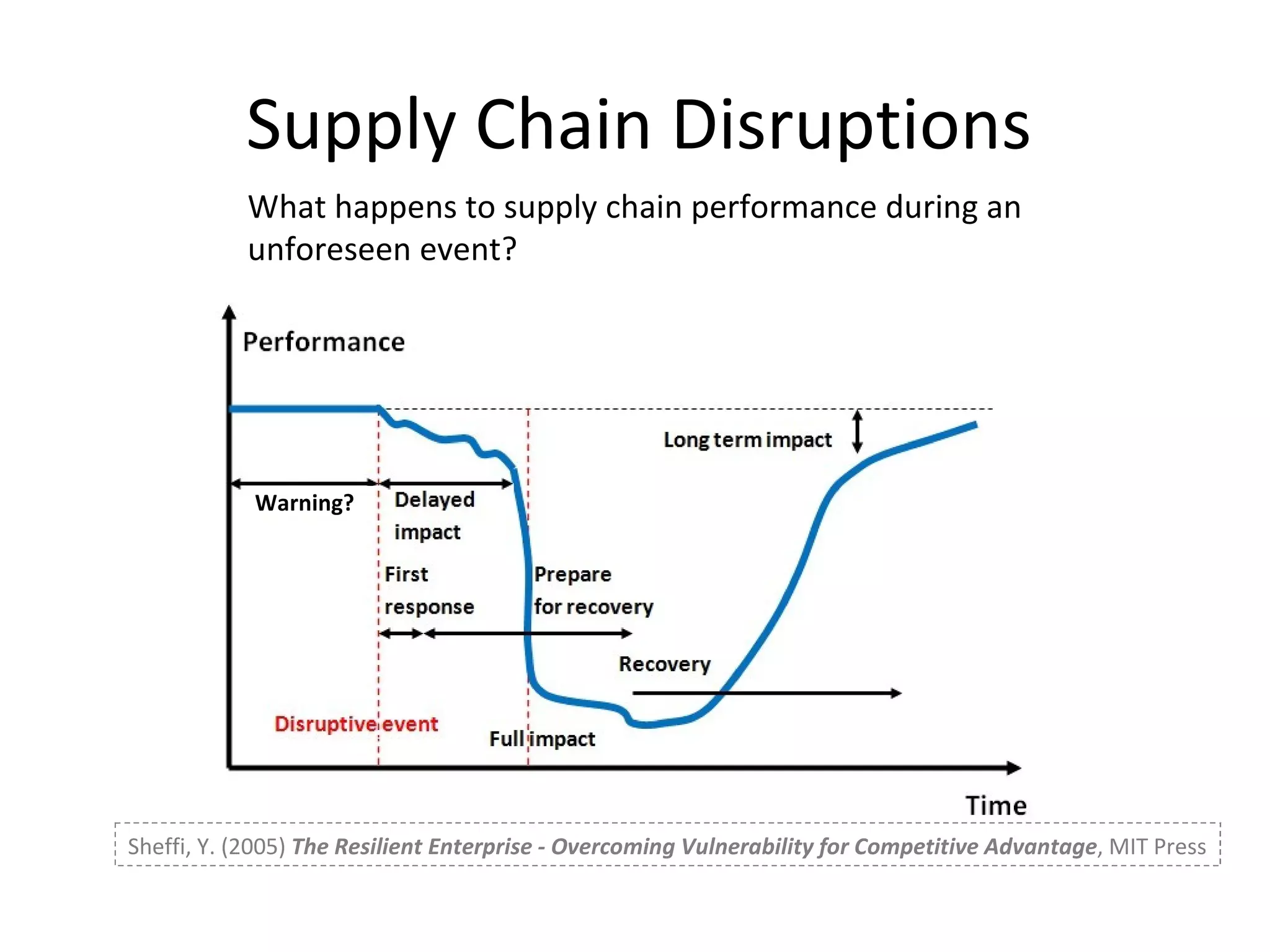

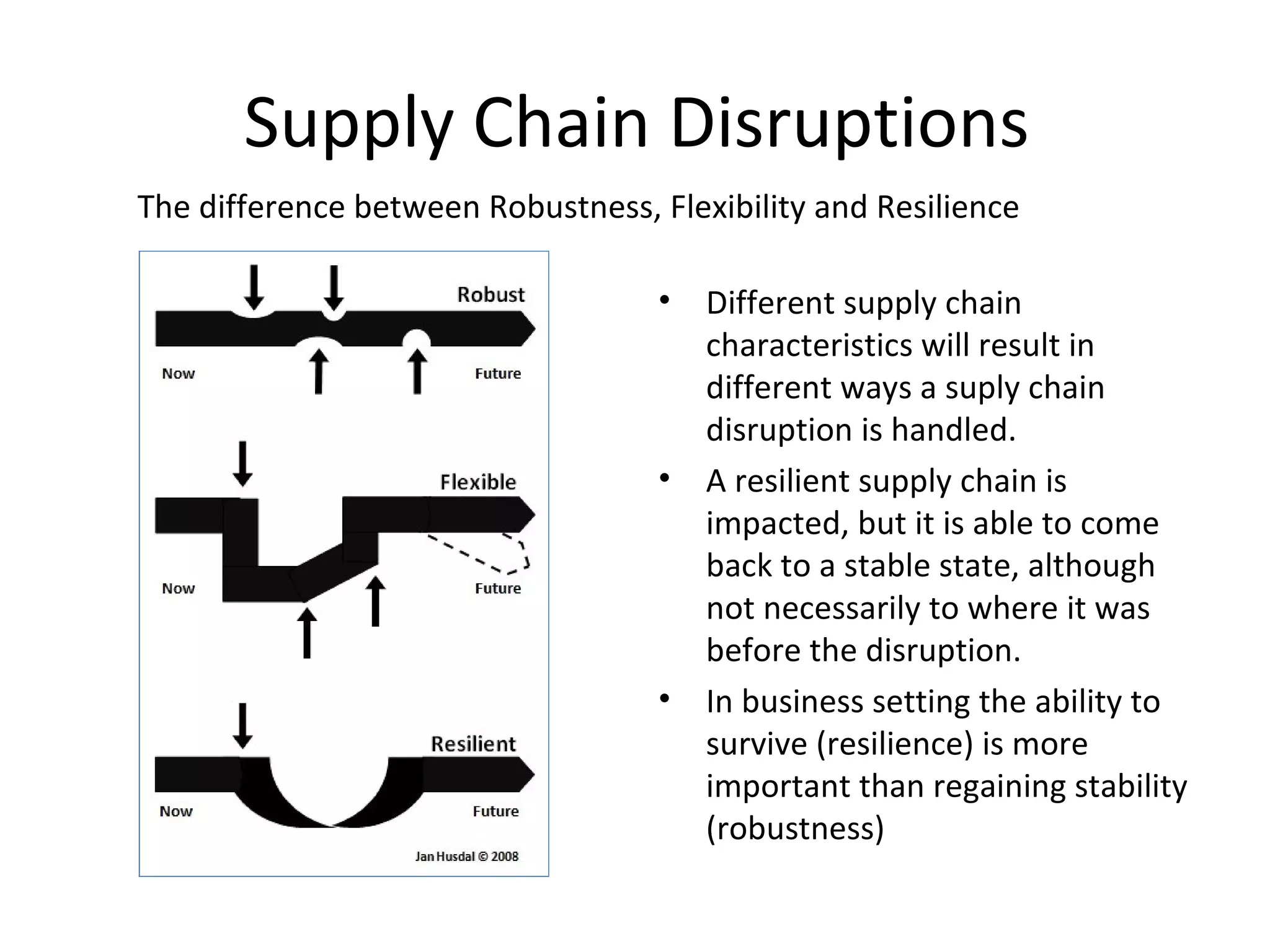

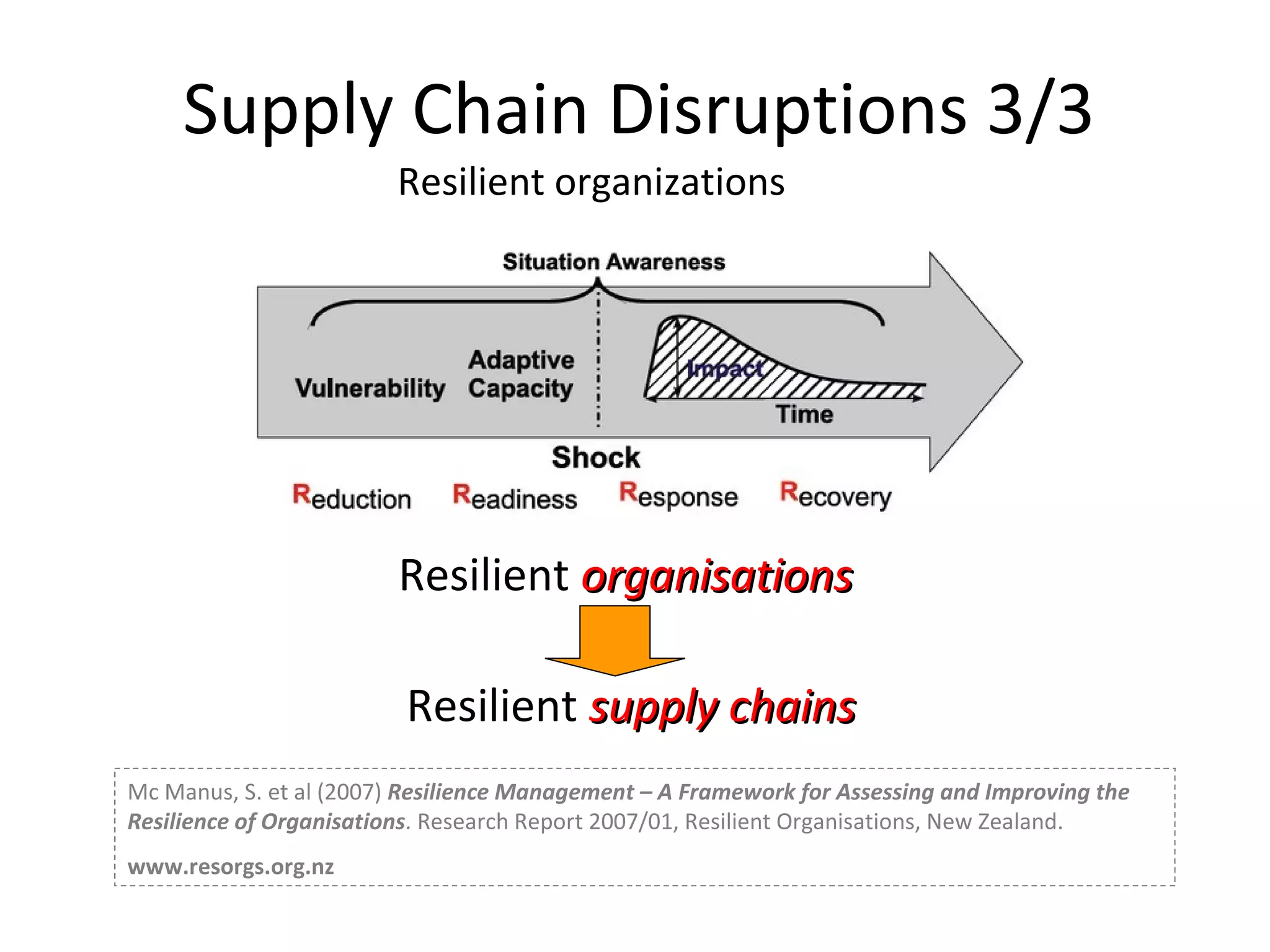

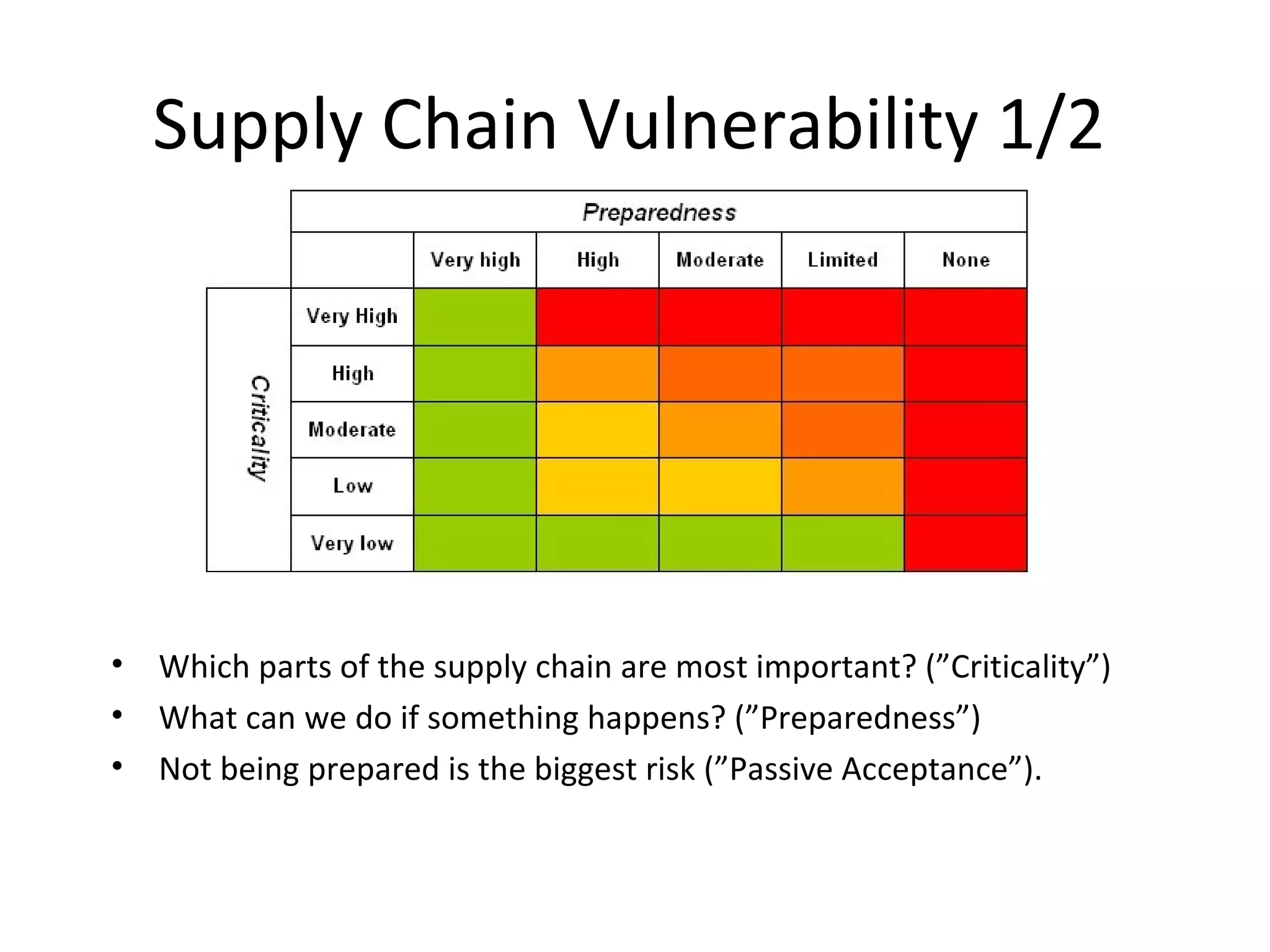

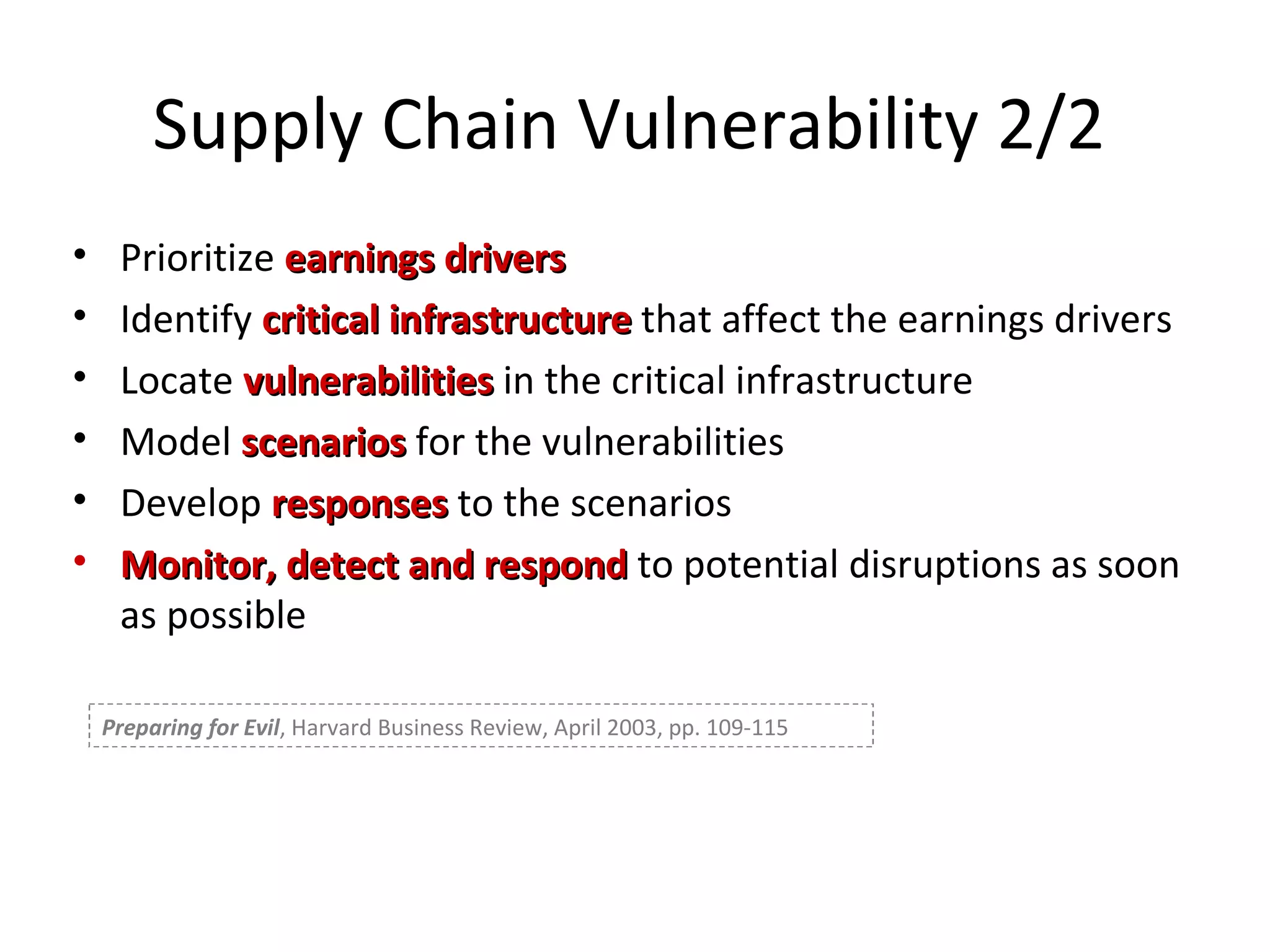

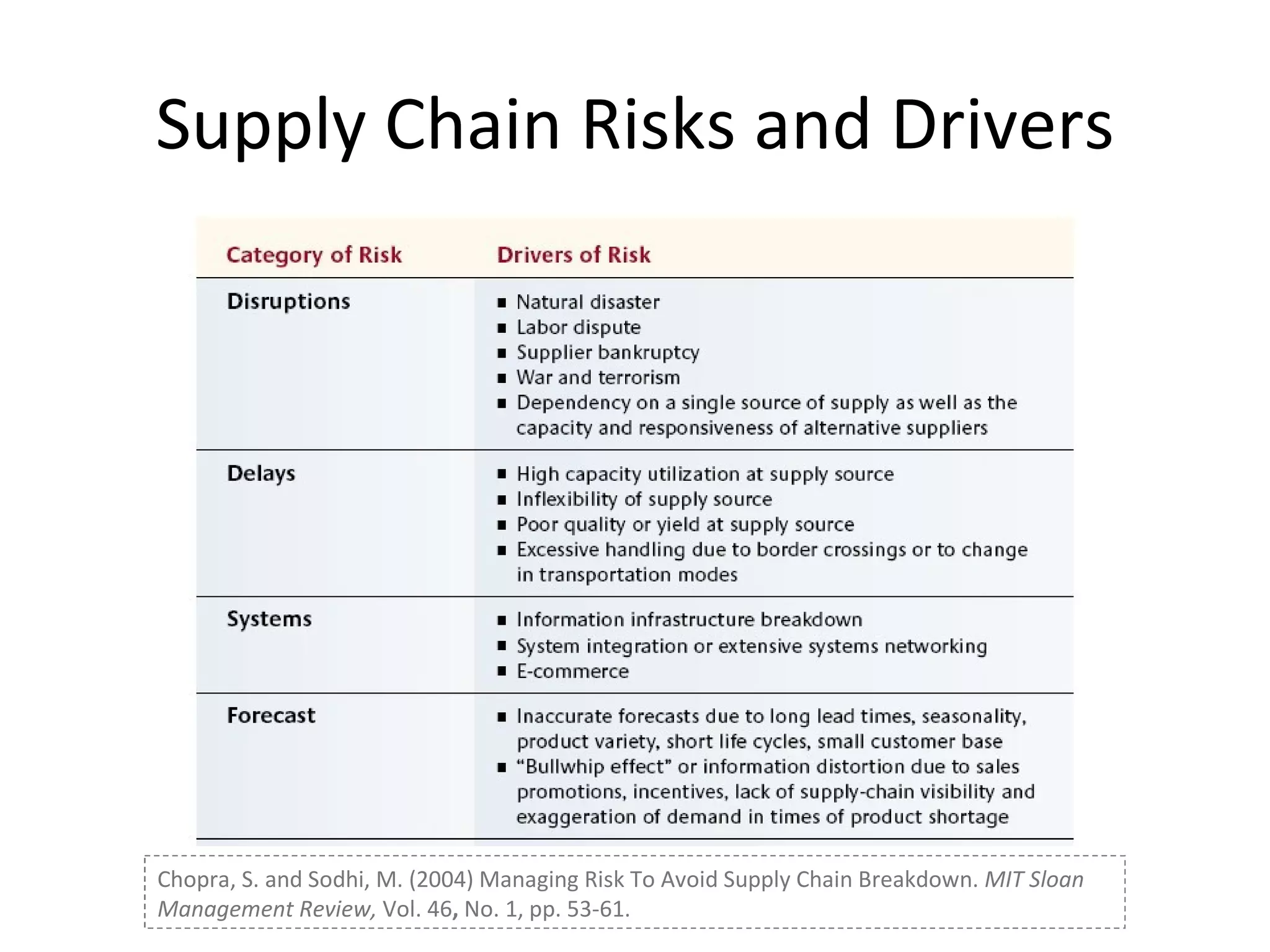

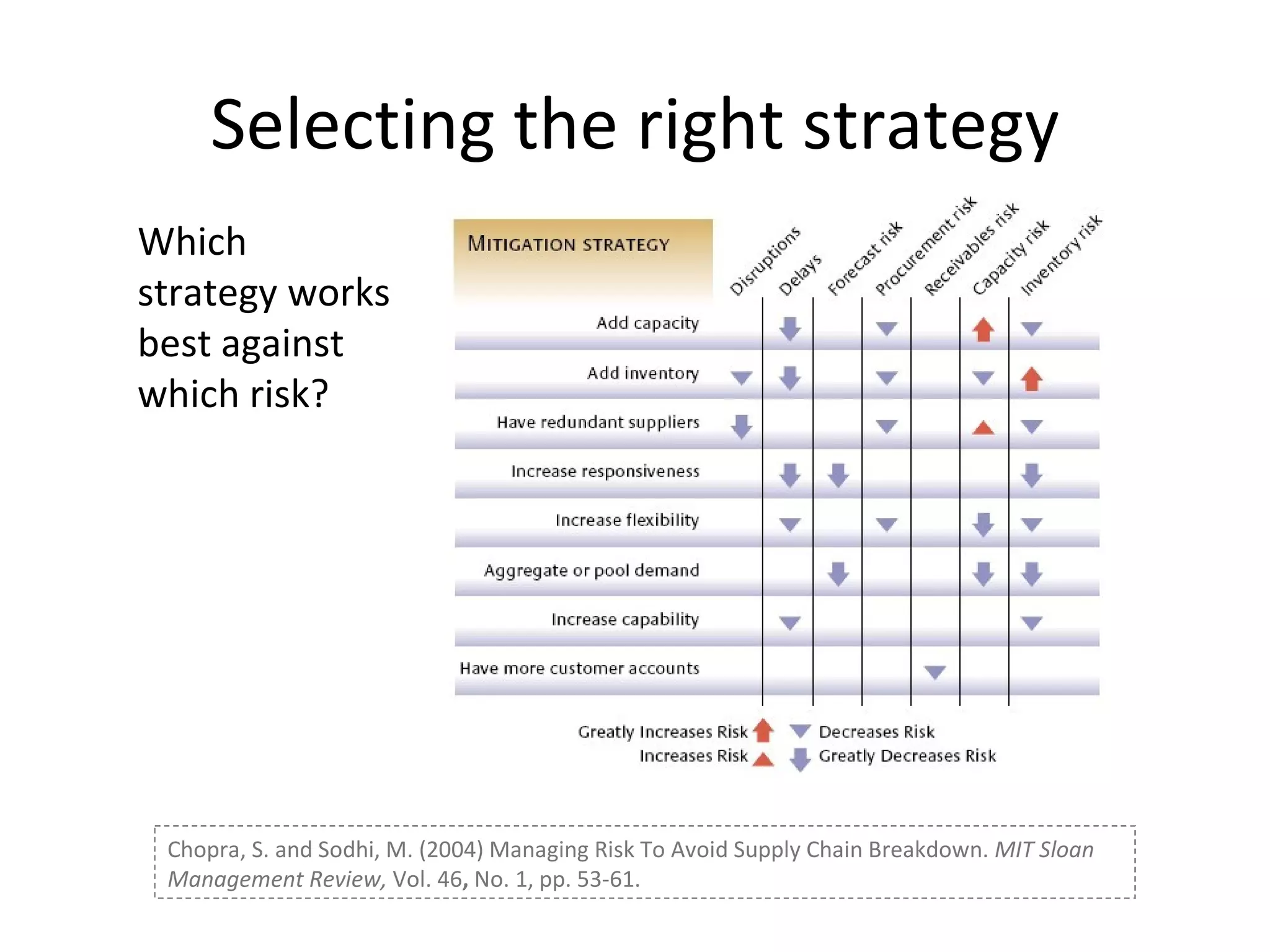

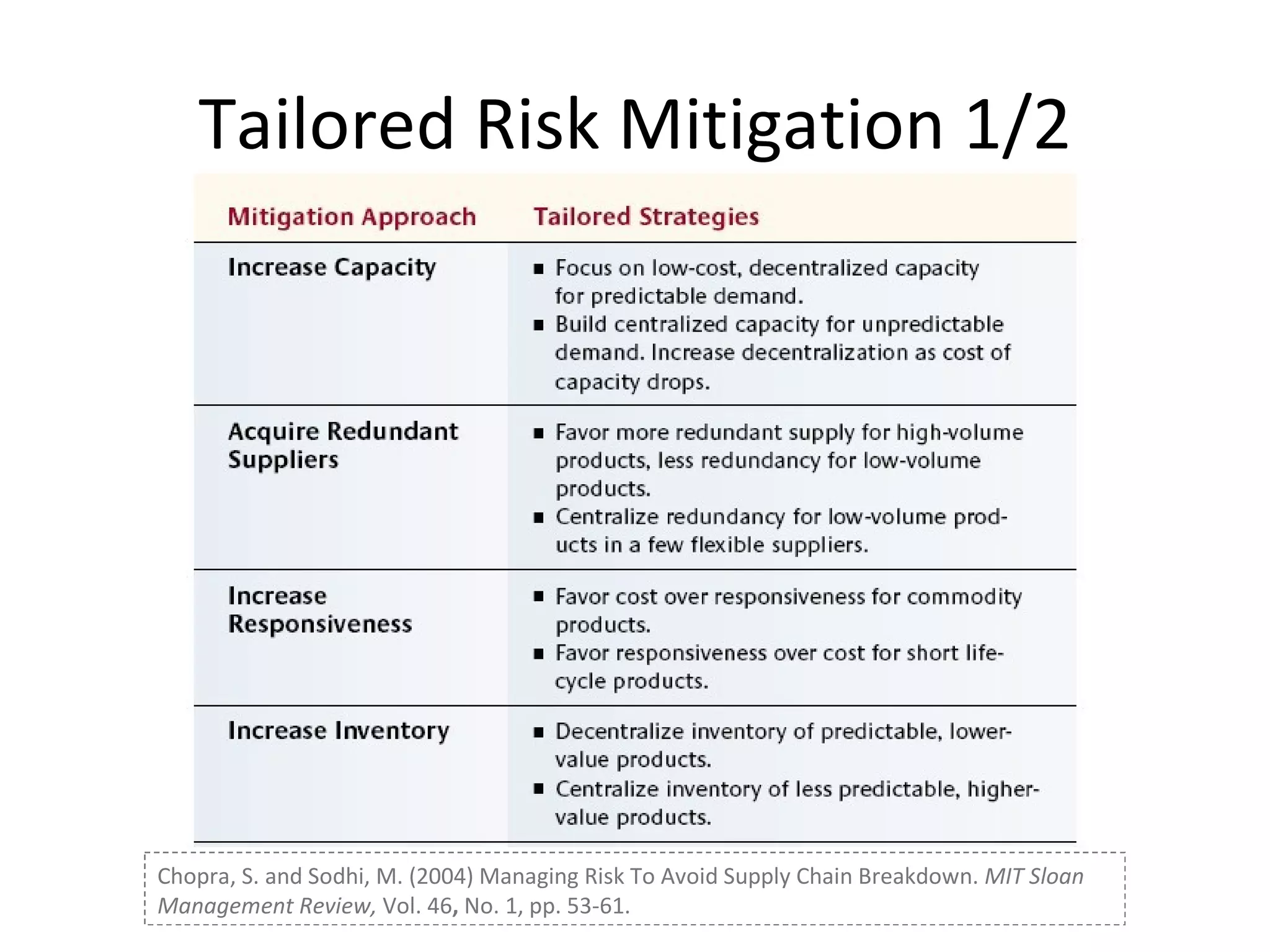

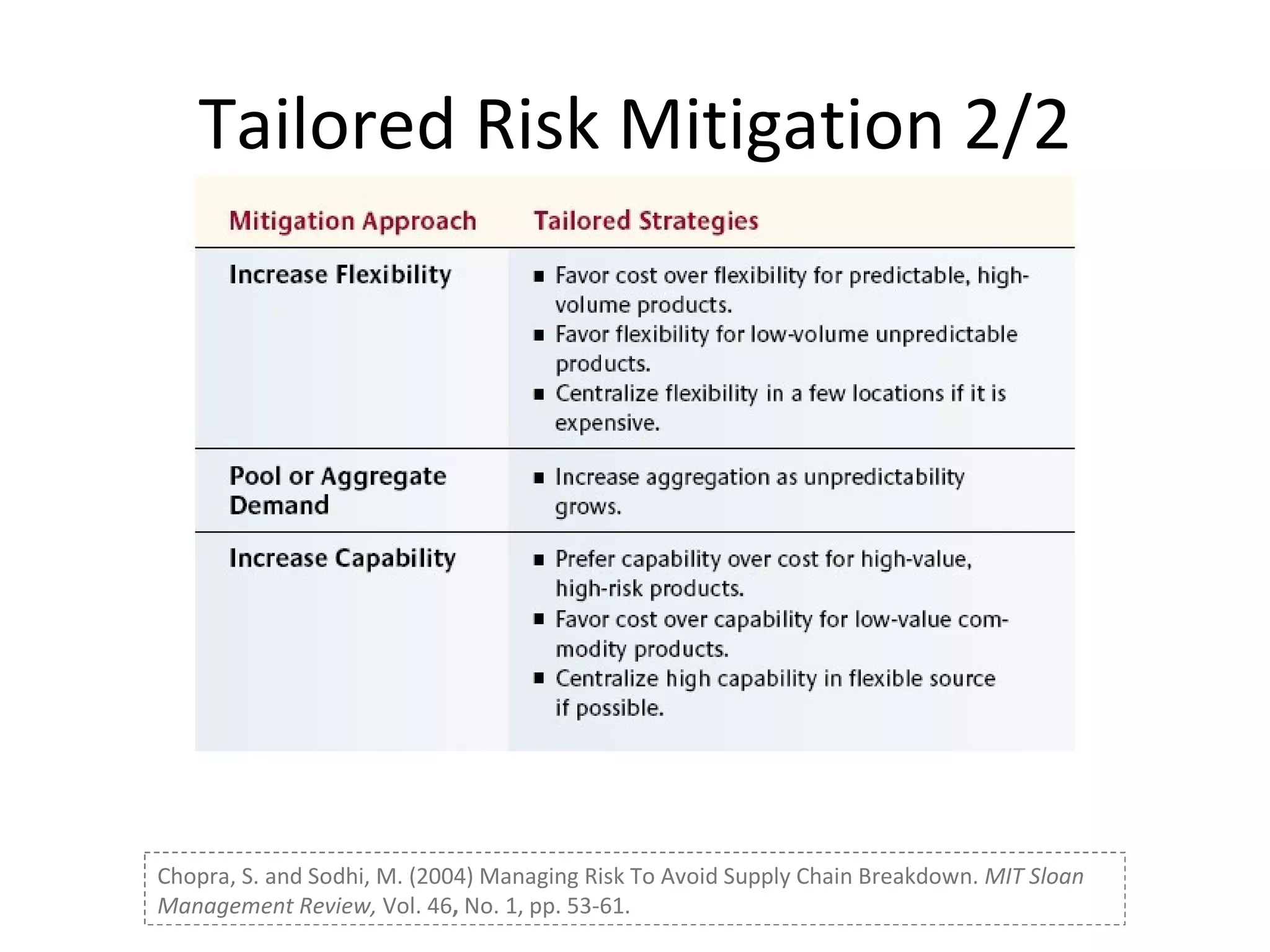

The document discusses supply chain risk. It defines supply chain risk and identifies various types of risks including supply risks, demand risks, and environmental risks. It also discusses strategies for managing supply chain risk such as avoidance, postponement, hedging, control, and risk transfer. Effective supply chain risk management involves understanding risk sources and drivers, identifying critical parts of the supply chain, establishing contingency plans, and working collaboratively with suppliers and customers.