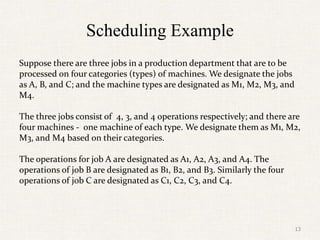

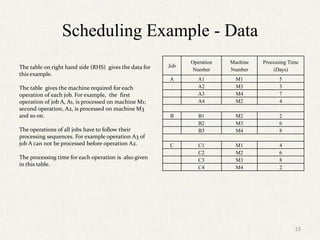

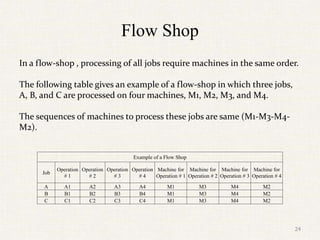

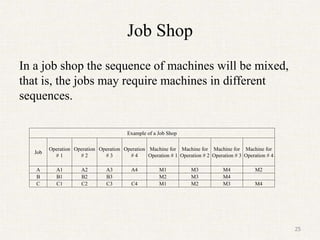

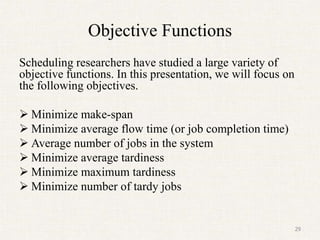

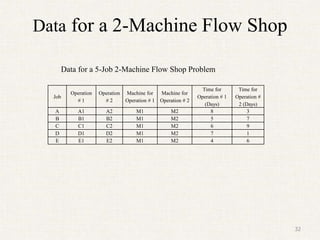

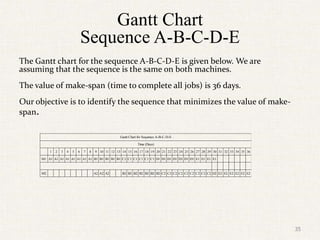

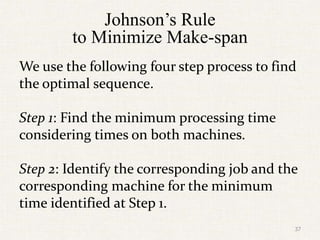

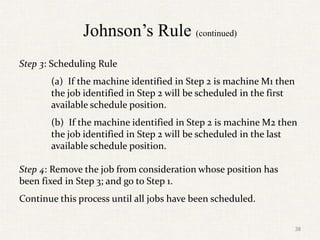

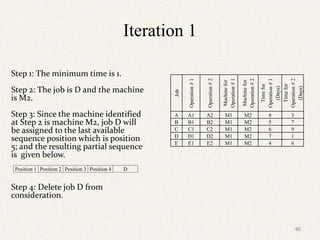

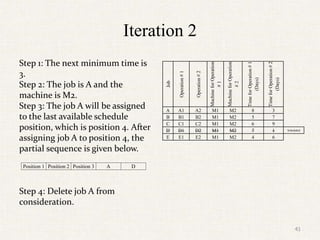

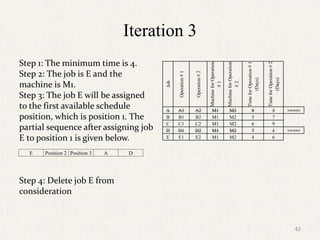

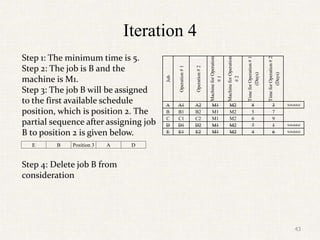

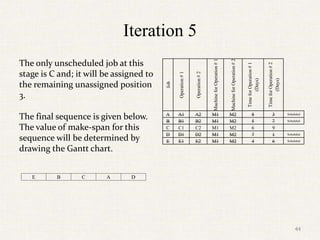

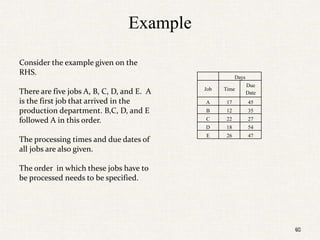

The document discusses production scheduling concepts including loading, sequencing, and scheduling. Loading assigns work to facilities. Sequencing establishes job order at each facility based on priority rules. Scheduling specifies job start/end times. Scheduling problems can be classified by machine sequence, number of machines, processing times, and objectives like minimizing completion time. The example shows scheduling a 2-machine flow shop to minimize make-span using a Gantt chart. Determining the optimal job sequence from the 120 possibilities is the goal.