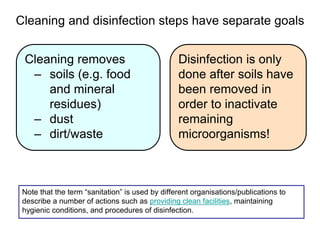

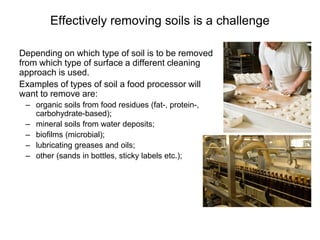

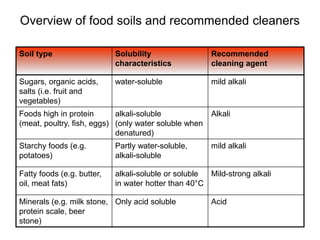

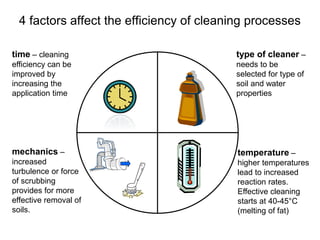

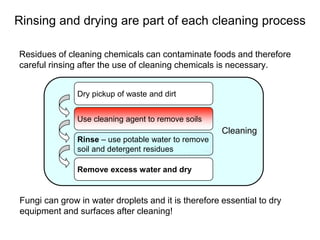

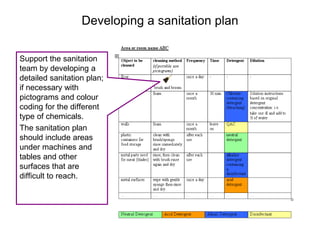

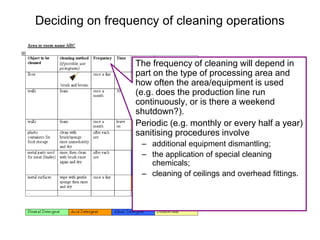

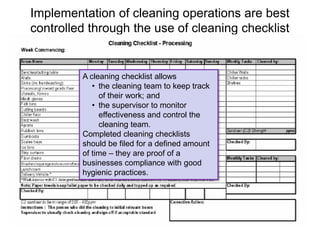

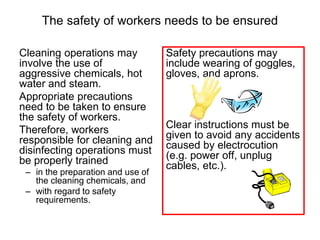

This presentation outlines key principles of sanitation in food premises, focusing on the importance of cleaning and disinfection for food safety and quality. It covers methods for removing various types of soils, appropriate cleaning agents, disinfection techniques, and the essential steps for developing and managing a sanitation program. Regular evaluation and monitoring of sanitation processes are emphasized to ensure effectiveness and compliance with hygiene regulations.