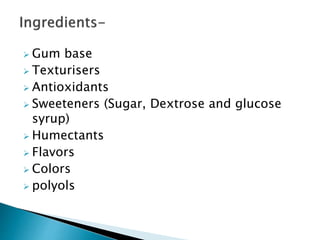

1) Chewing gum is a soft substance designed to be chewed but not swallowed. It is composed of gum base, sweeteners, softeners, flavors, and colors.

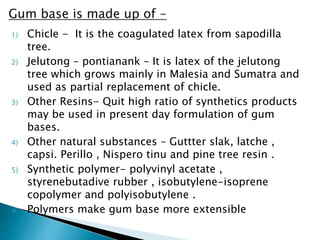

2) People have chewed natural materials like tree bark for centuries. Modern gum is derived from chicle, the latex from the sapodilla tree.

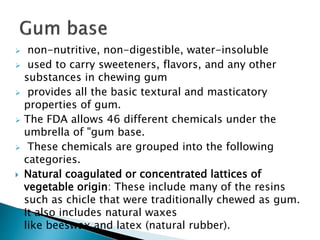

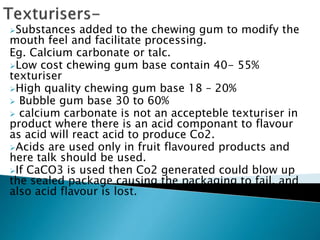

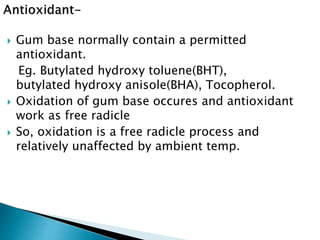

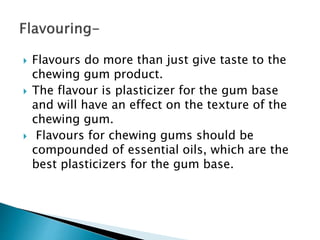

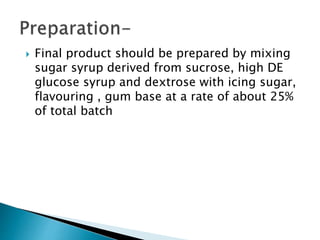

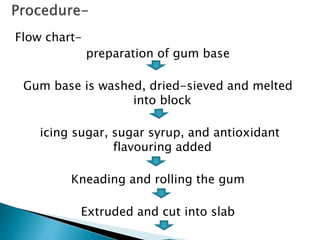

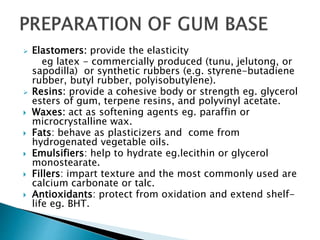

3) Gum base provides the elastic properties while other ingredients like sugars and flavors are added. The gum is produced through mixing, kneading, rolling, cutting and packaging.