1. Sampling of minerals involves collecting portions of rocks or ores to determine their quality and composition. There are different types and methods of sampling depending on whether it is done above or below ground.

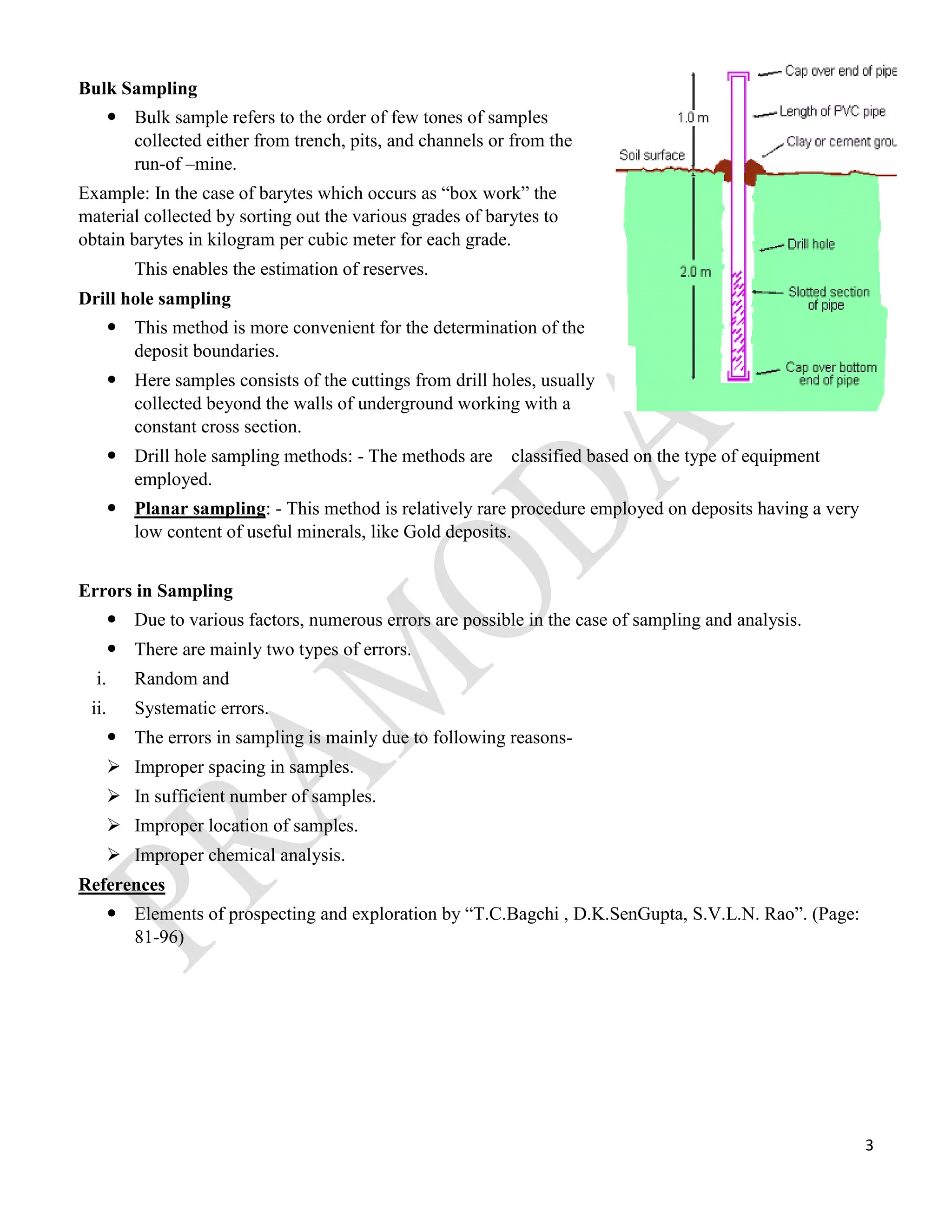

2. Common sampling methods include grab sampling, channel sampling, chip sampling, and drill hole sampling. Grab sampling involves collecting rock specimens while channel sampling cuts channels across rock faces.

3. Sampling seeks to provide a representative sample of the whole deposit but can be subject to random and systematic errors from factors like improper spacing, insufficient samples, or incorrect analysis. Proper sampling techniques aim to minimize these errors.