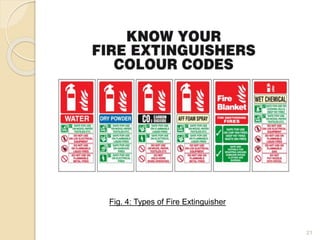

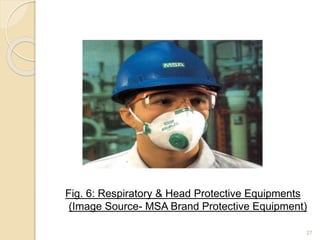

This seminar presentation summarizes safety hazards and protections in the foundry industry. It discusses various physical, respiratory, noise, fire and explosion, and eye hazards. It recommends preventative measures like enclosed and separated work areas, automated equipment, and protective equipment. The presentation also describes different types of personal protective equipment (PPE) used in foundries, including head, respiratory, skin, eye, hearing, and whole-body protections. It stresses the importance of safety training and strict PPE requirements to minimize hazards in the dangerous foundry environment.