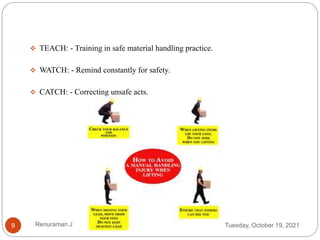

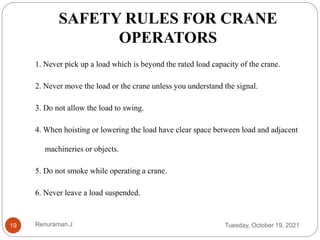

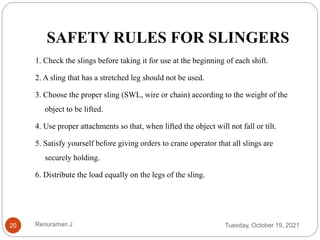

This document discusses industrial safety and material handling. It covers proper procedures for manual material handling, safe operation of cranes and other mechanized equipment, and risks associated with different material types. The key points are that material handling makes up a major part of industry and causes many accidents; safe practices like following lifting procedures, using lifting aids, and clear communication can reduce risks; and different materials require appropriate protective equipment and handling methods.