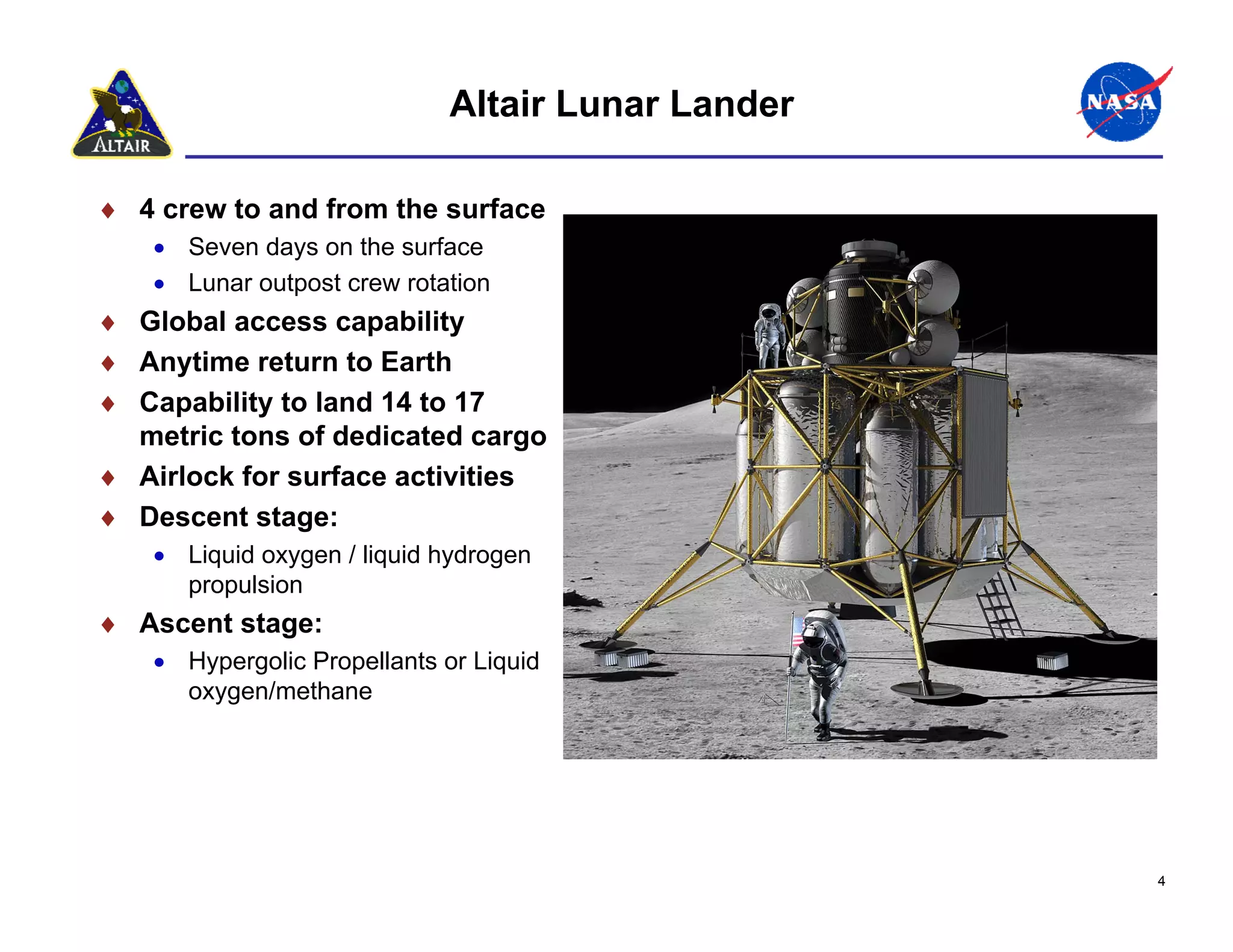

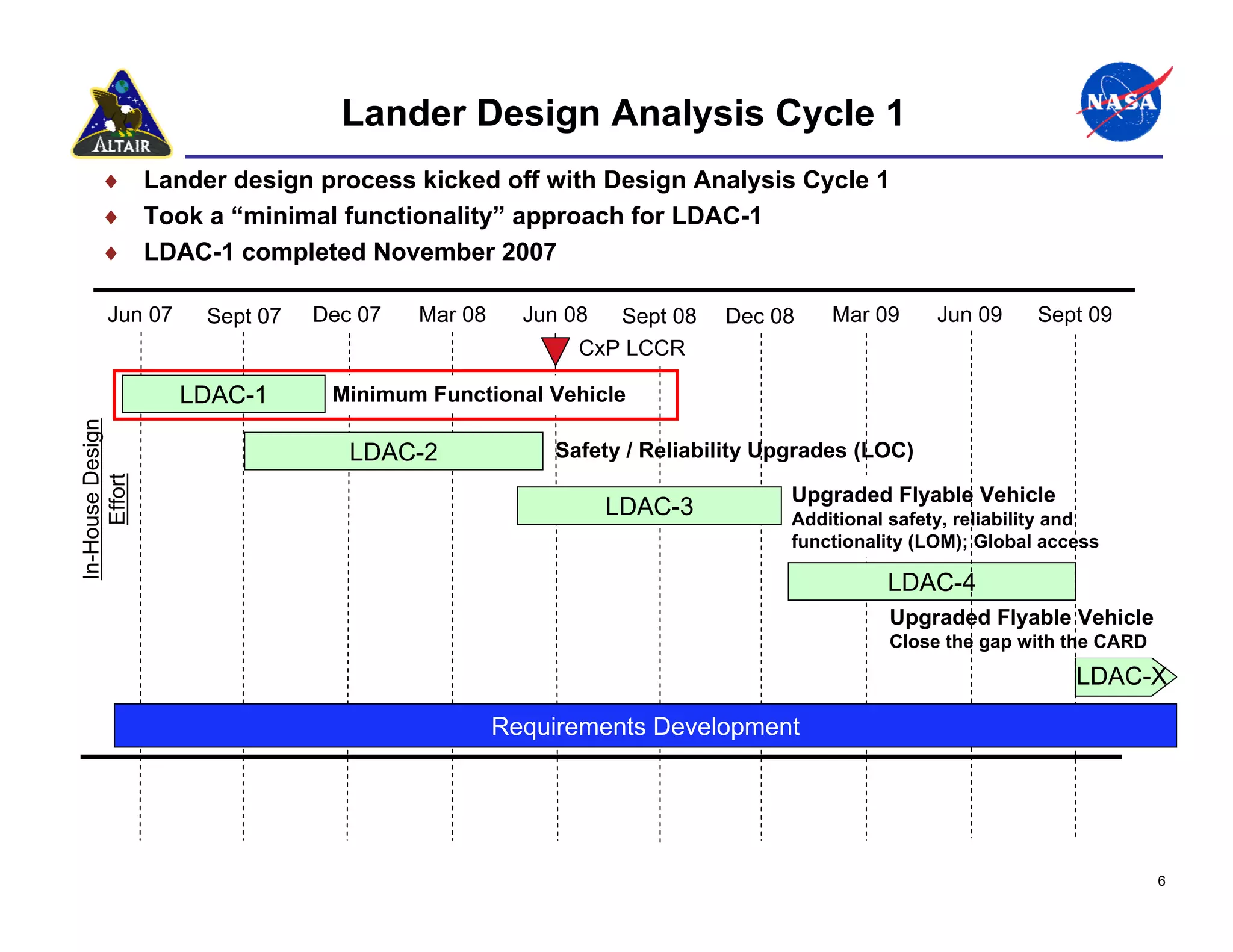

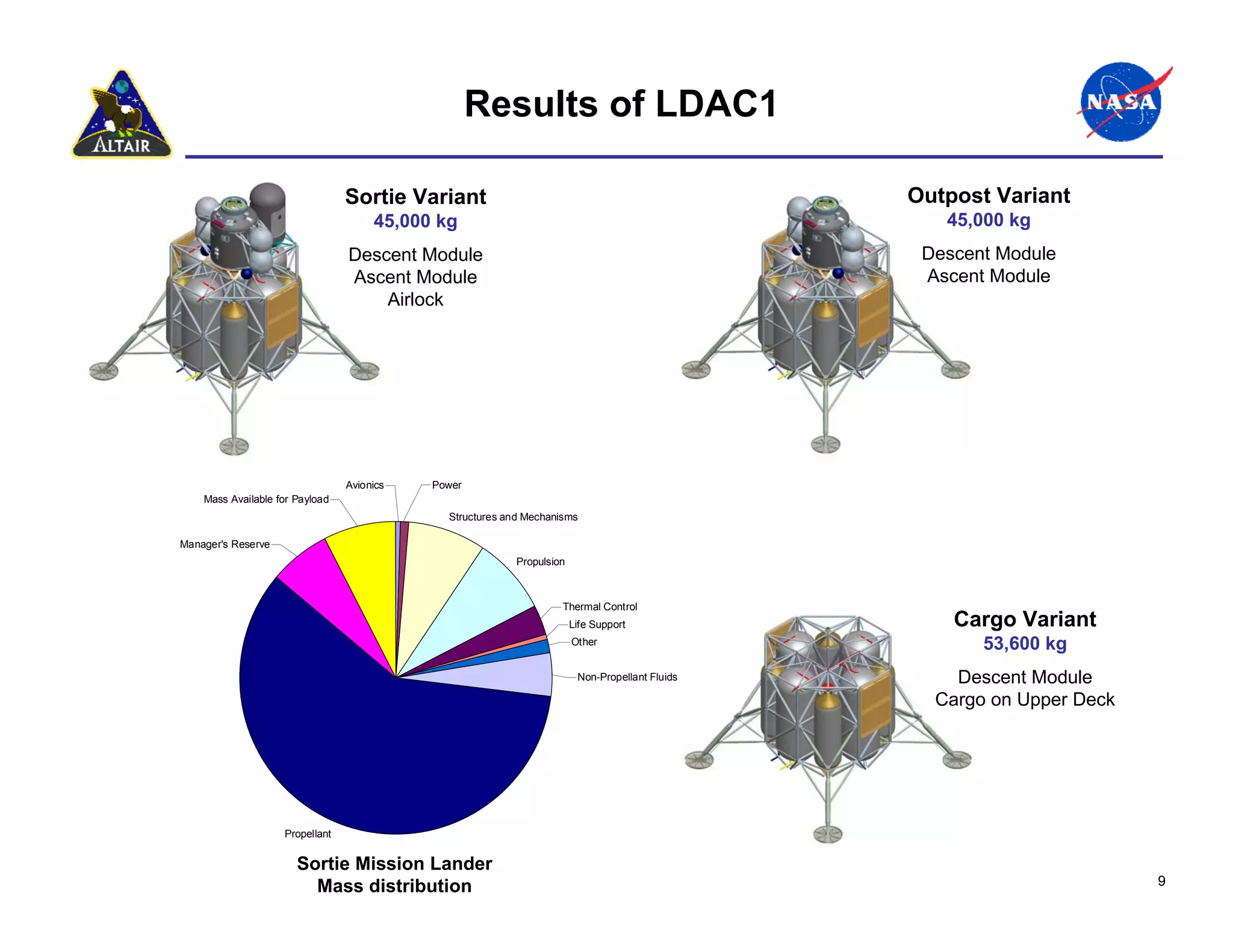

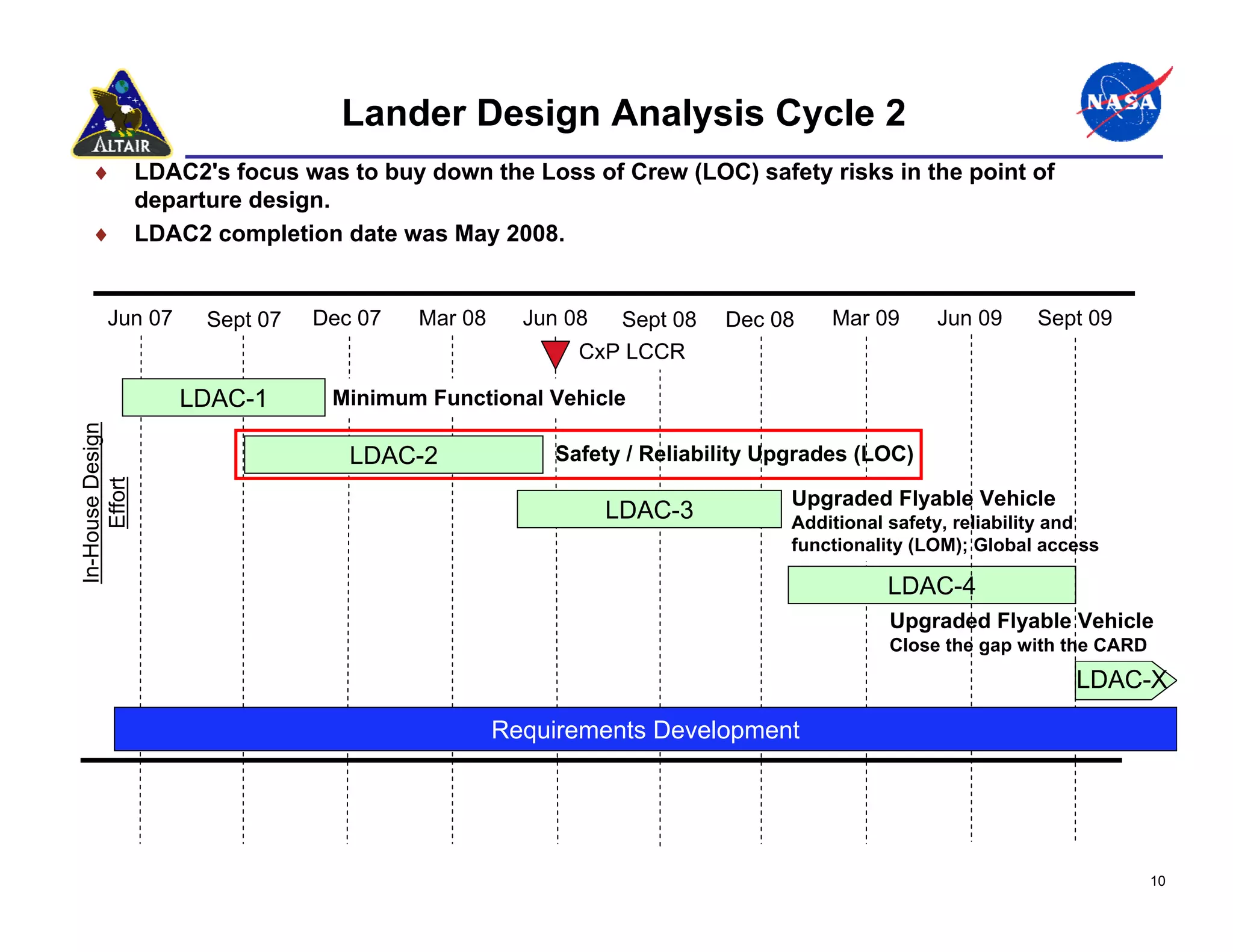

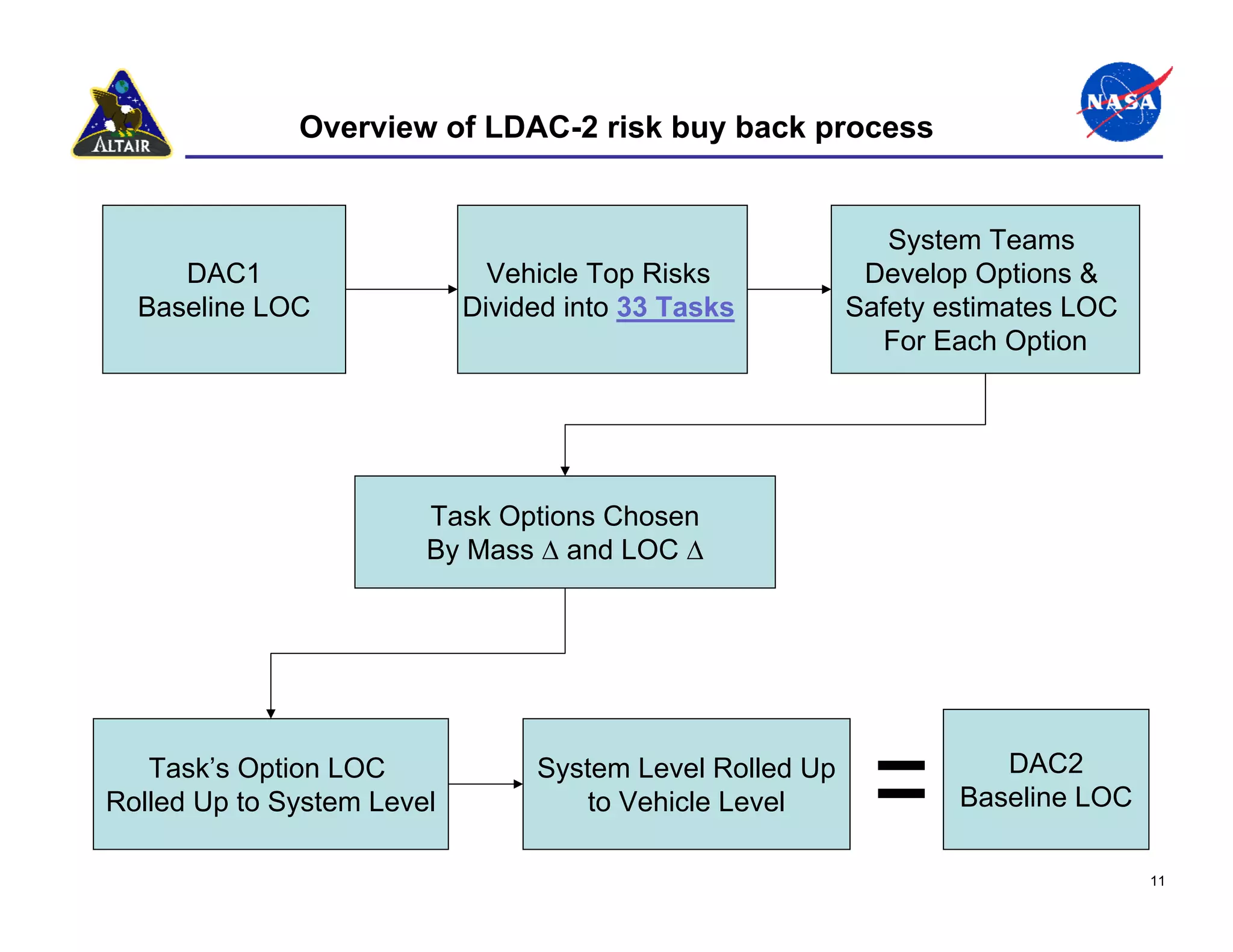

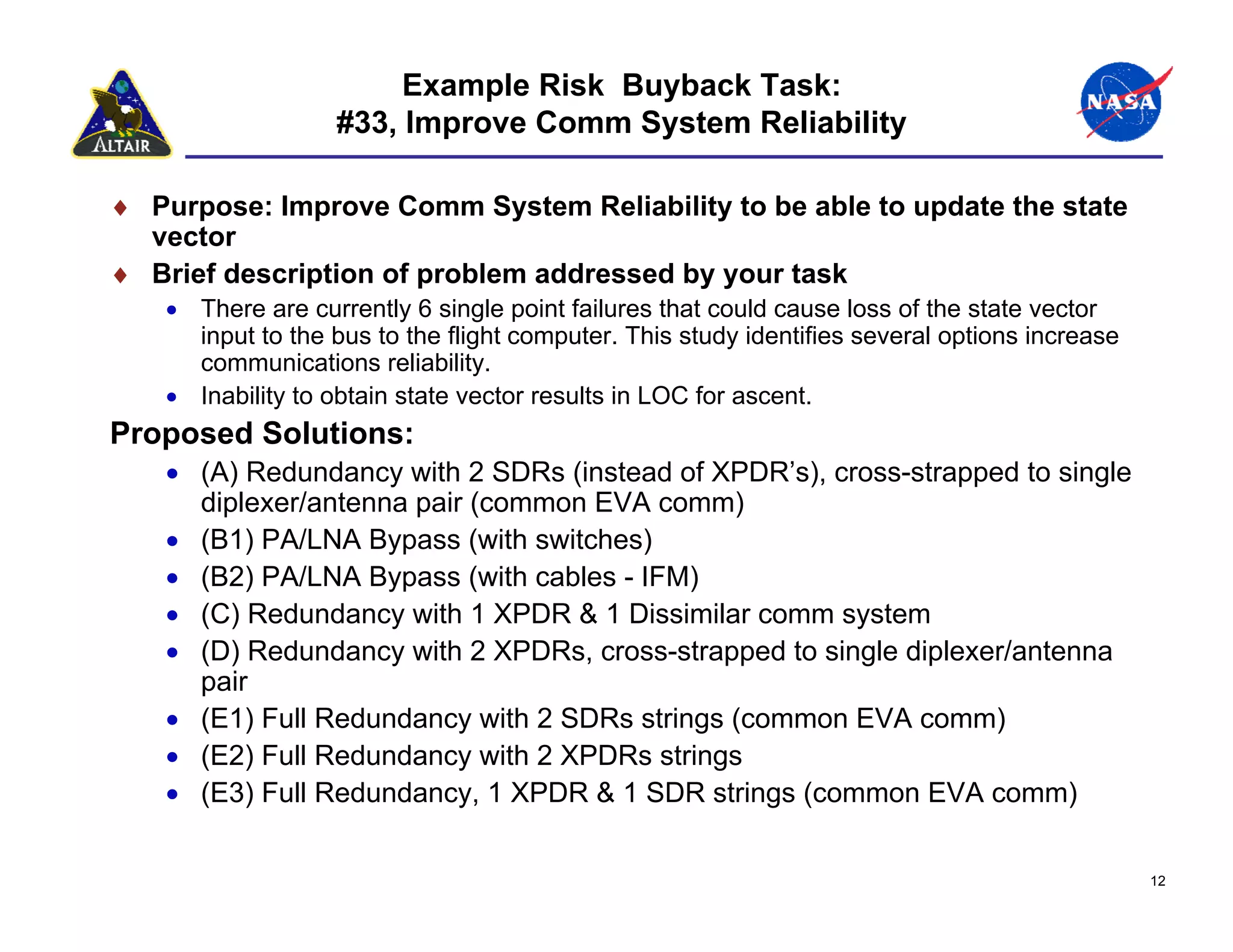

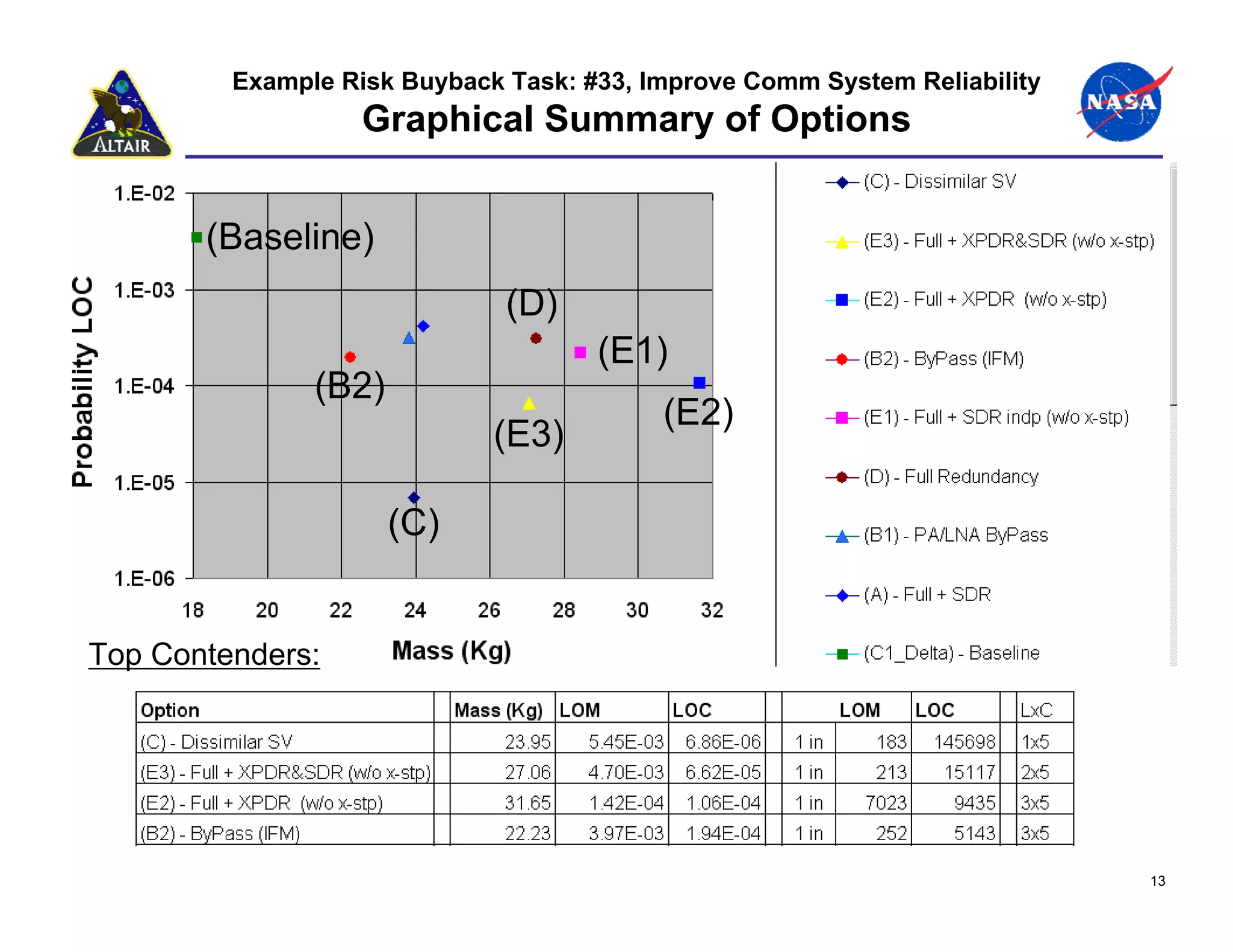

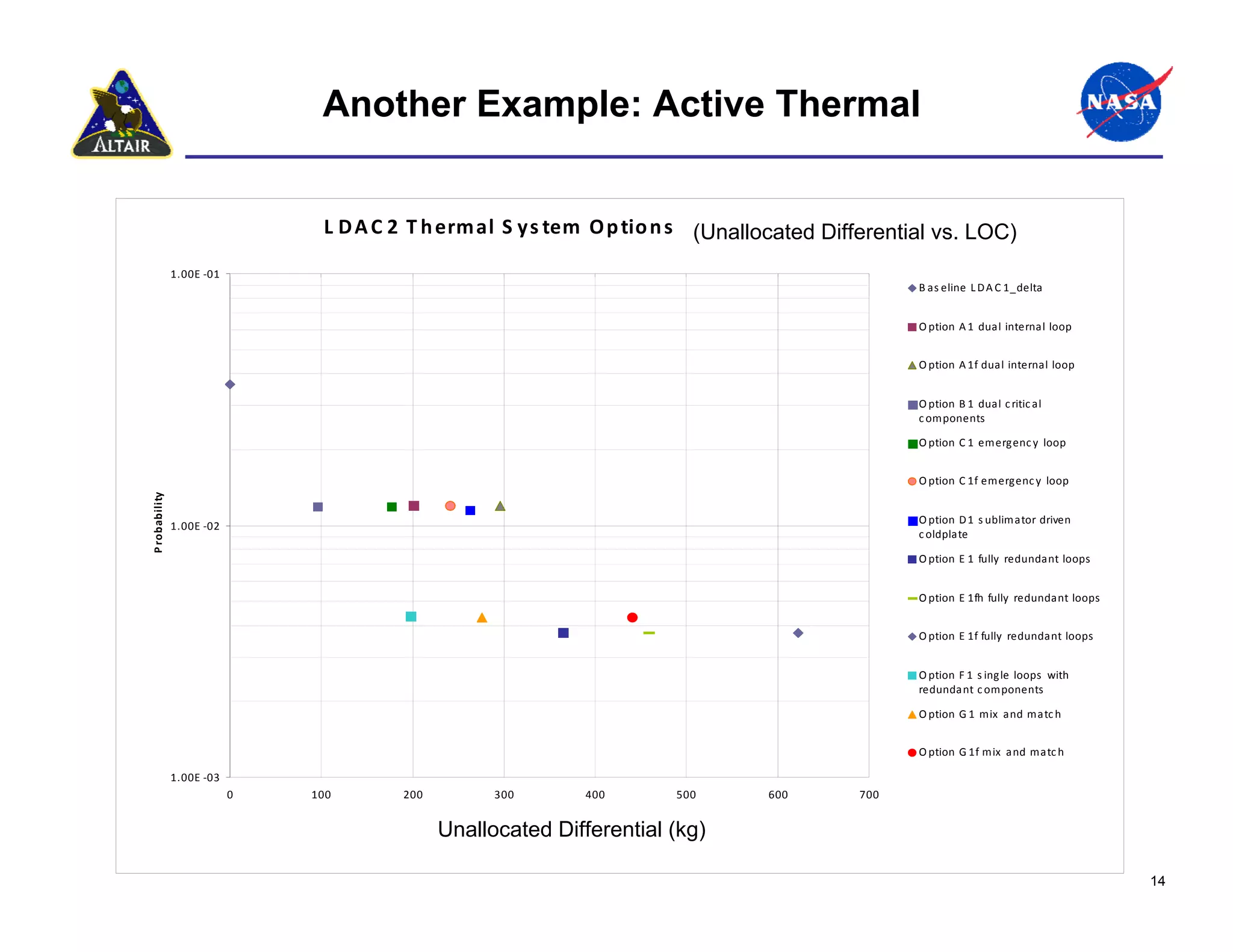

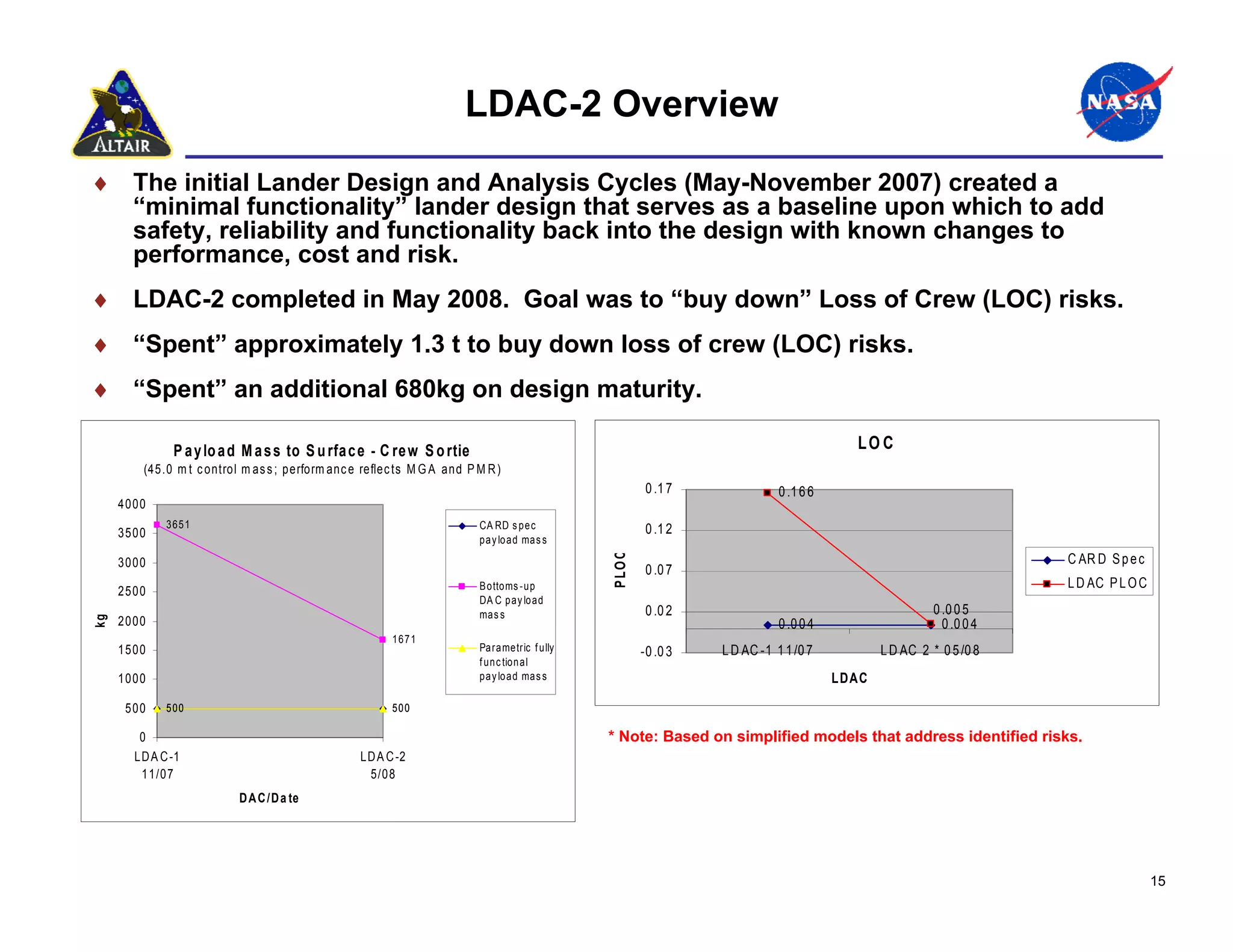

LDAC-1 developed a minimum functionality lunar lander design using a risk-informed approach to meet basic mission requirements. LDAC-2 then focused on reducing risks to crew safety by adding redundancy and reliability upgrades. The goal was to design a lander that provided adequate safety for crew with a design optimized for mass.