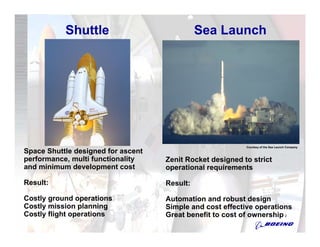

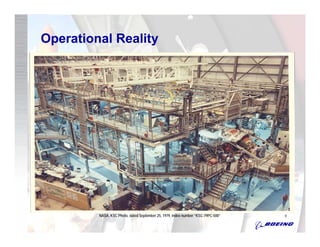

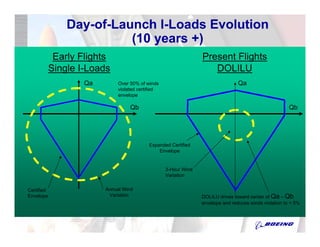

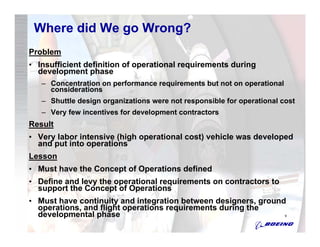

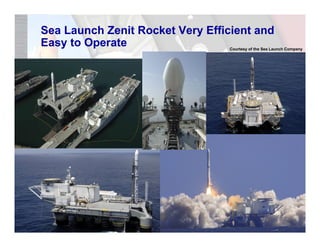

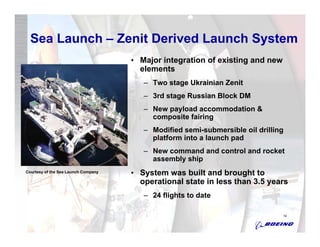

The document compares the operational complexity and costs of the Space Shuttle versus the Sea Launch Zenit rocket. [1] The Space Shuttle was designed for performance but not operational efficiency, resulting in costly ground, mission planning, and flight operations. [2] In contrast, the Zenit rocket was designed from the start to have automated and robust processes to keep operations simple and costs low. [3] The key lesson is that designing a launch system with operational requirements in mind from the beginning leads to much more efficient operations long-term.