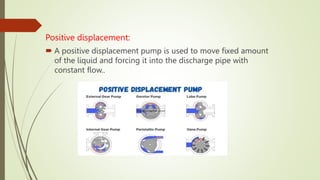

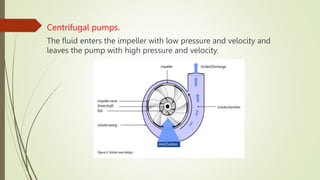

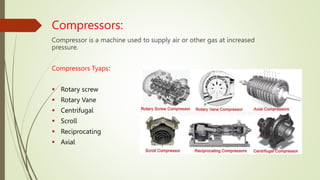

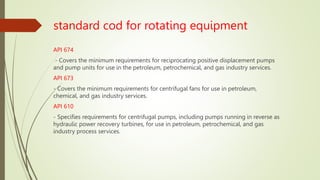

This mechanical project presentation discusses rotating equipment such as pumps, turbines, blowers, and compressors. It outlines the main types of each, including positive displacement and centrifugal pumps, steam, wind, gas, and water turbines, and rotary screw, rotary vane, centrifugal, scroll, and reciprocating compressors. The presentation also discusses inspection of rotating equipment components through visual inspection and tools such as tachometers, borescopes, vibration meters, and hydrostatic test pumps. Finally, it lists several relevant API standards for rotating equipment.