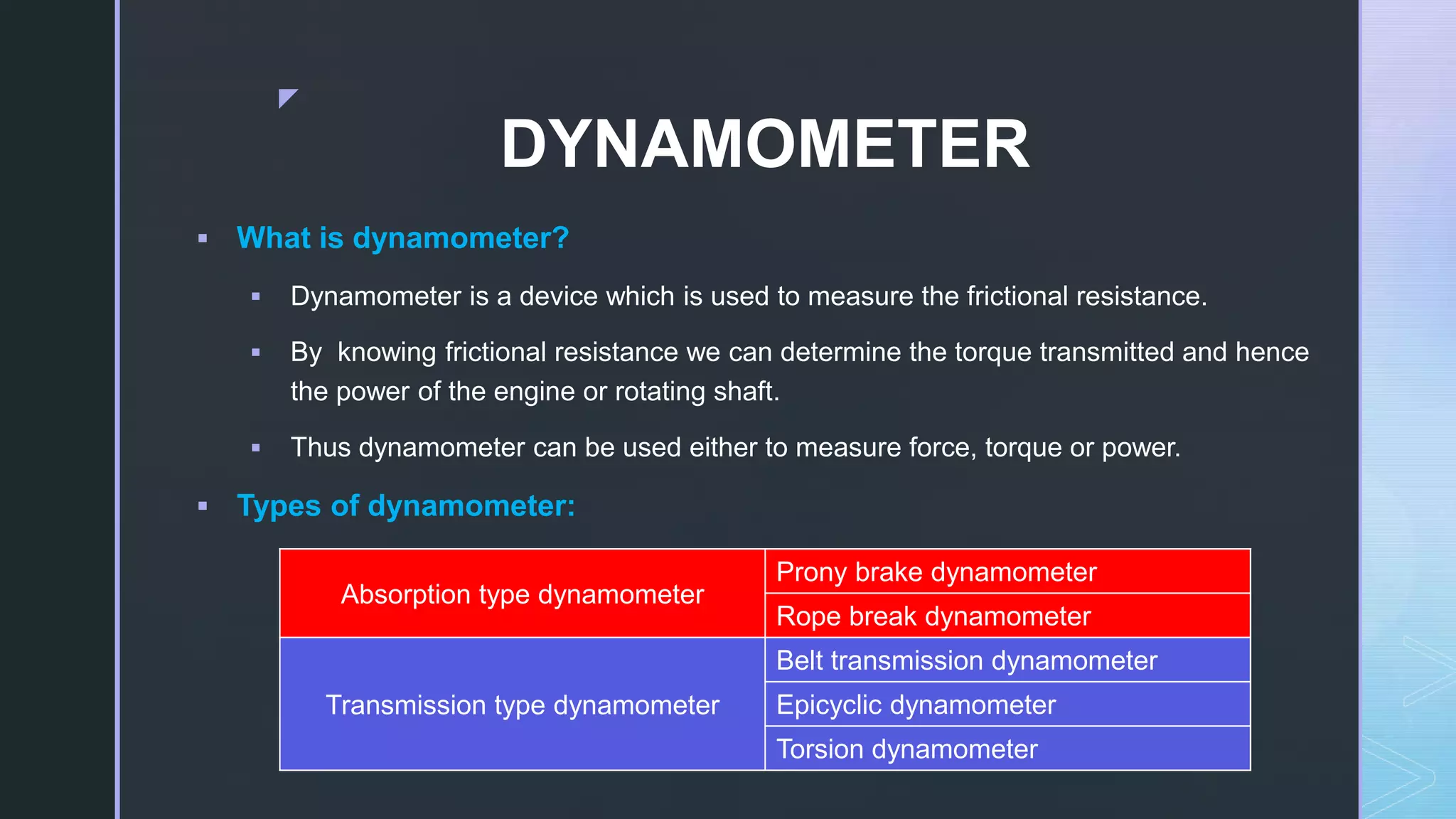

This document describes a rope brake dynamometer. It contains sections on dynamometers in general, rope brake dynamometers specifically, an example calculation of brake power using a rope brake dynamometer, and references. A rope brake dynamometer consists of one or more ropes wrapped around a pulley connected to the engine shaft. A weight is attached to one end of the rope and a spring balance to the other to measure the frictional resistance, from which the torque and power can be calculated. An example calculation is shown using data collected from a lab experiment.

![z

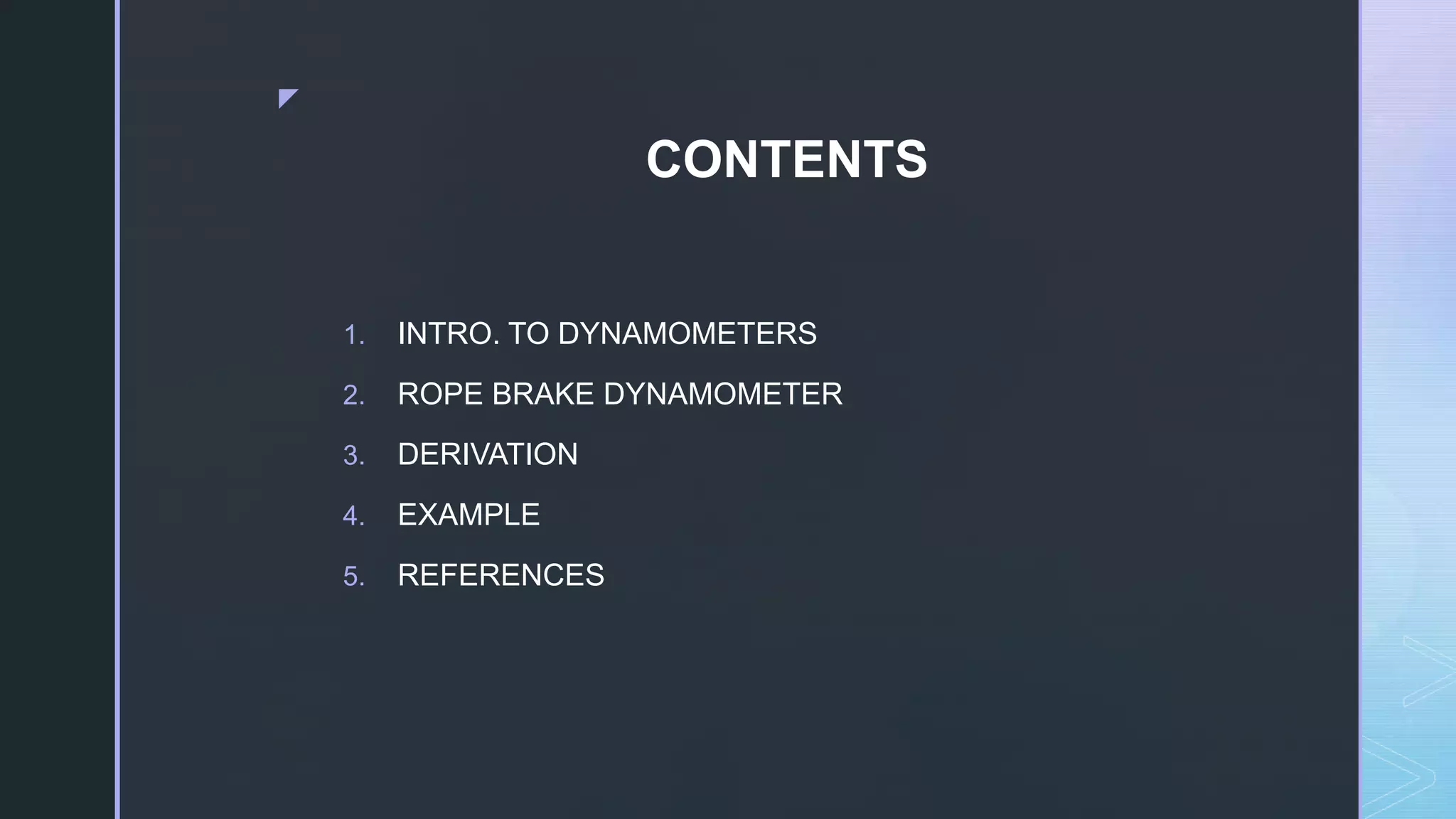

EQUATION OF BREAK POWER

Let,

W = dead weight of suspended weight

S = spring balance reading

D = diameter of pulley or drum

N = speed of the engine

d = diameter of the rope

(W-s) = net break load

Frictional torque due to rope =

[ (𝑛𝑒𝑡 𝑙𝑜𝑎𝑑 𝑜𝑛 𝑏𝑟𝑒𝑎𝑘 × 𝑑𝑖𝑠𝑡𝑎𝑎𝑛𝑐𝑒 𝑜𝑓 𝑙𝑜𝑎𝑑 𝑙𝑖𝑛𝑒 𝑓𝑟𝑜𝑚 𝑐𝑒𝑛𝑡𝑒𝑟 𝑜𝑓 𝑠ℎ𝑎𝑓𝑡) ]

= (𝑊 − 𝑆) ×

𝐷 + 𝑑

2](https://image.slidesharecdn.com/tom-170825172346/75/rope-brake-dynamometer-7-2048.jpg)