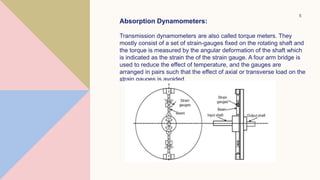

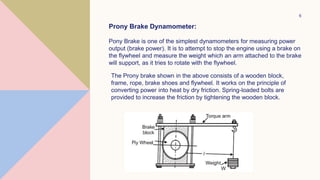

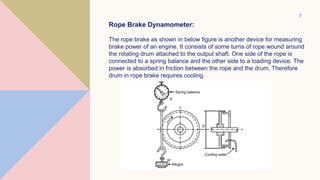

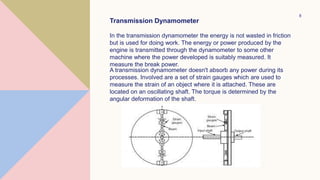

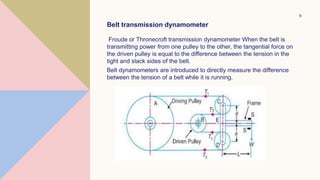

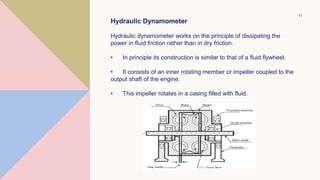

A dynamometer is a device used to measure force, torque, or power. It can measure the torque and power characteristics of engines and motors by simultaneously measuring torque and rotational speed. There are two main types of dynamometers: power absorption dynamometers, which measure and absorb the engine's power output, and power transmission dynamometers, also called torque meters, which transmit power to a load for measurement. Common power absorption dynamometers include Prony brake, rope brake, eddy current, hydraulic, and other types that dissipate absorbed power as heat. Power transmission dynamometers use strain gauges on a rotating shaft to measure torque.