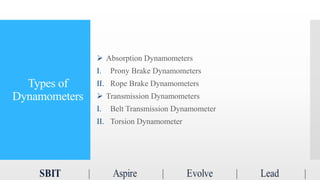

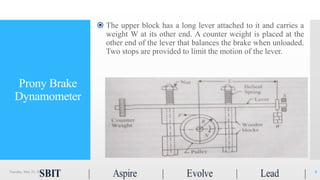

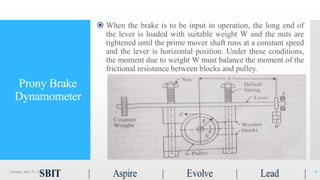

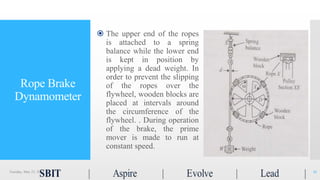

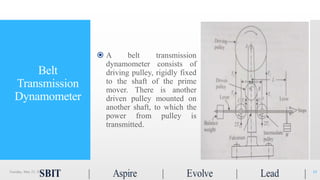

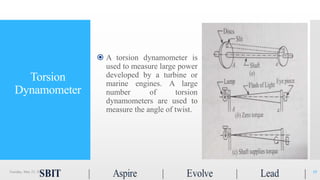

The document discusses two types of dynamometers: absorption and transmission. Absorption dynamometers measure power by absorbing the engine's power through friction, with examples being Prony brake and rope brake dynamometers. Transmission dynamometers measure power by transmitting it to another machine, like a belt transmission dynamometer which uses a belt and pulleys, or a torsion dynamometer which measures shaft twist.