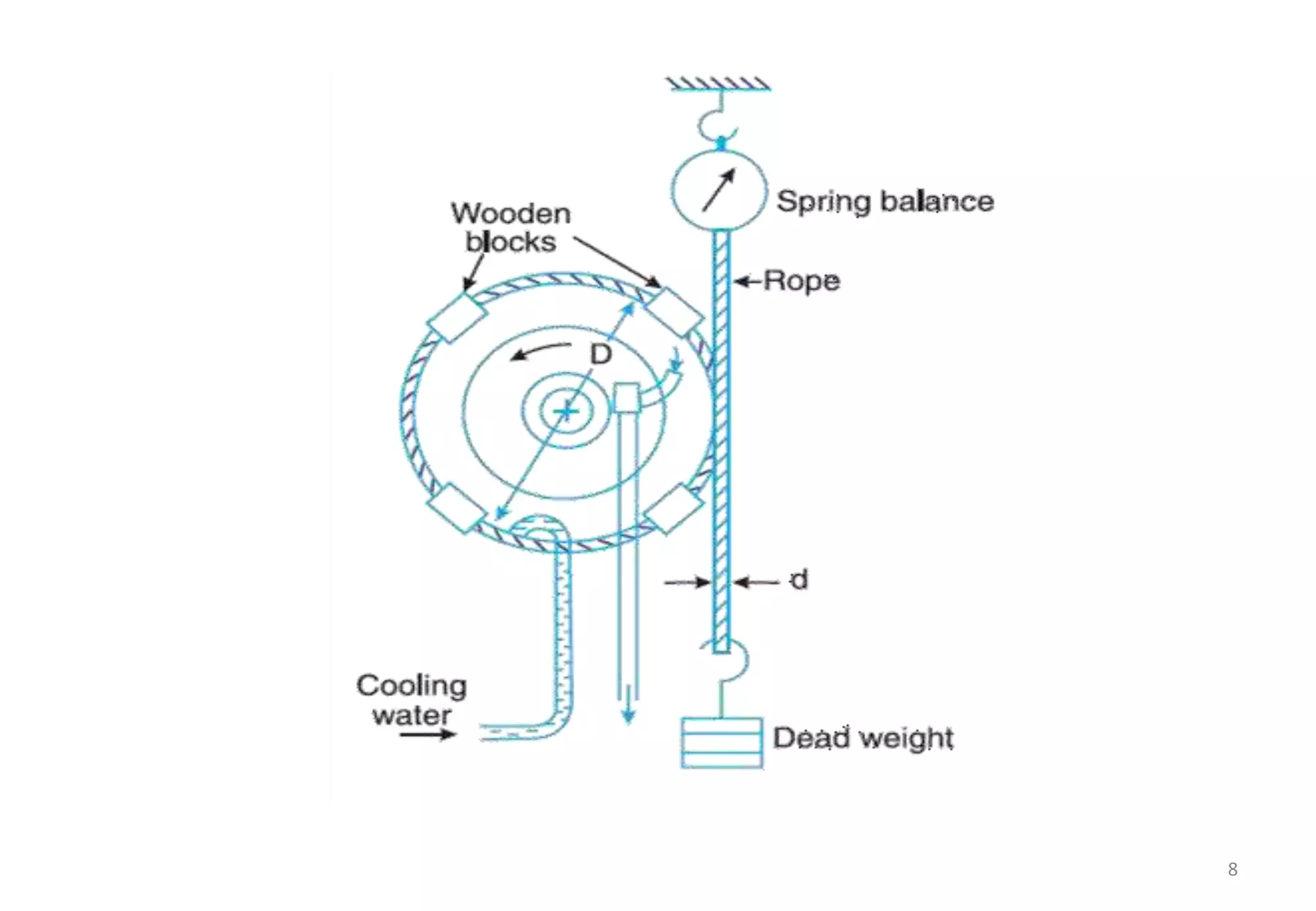

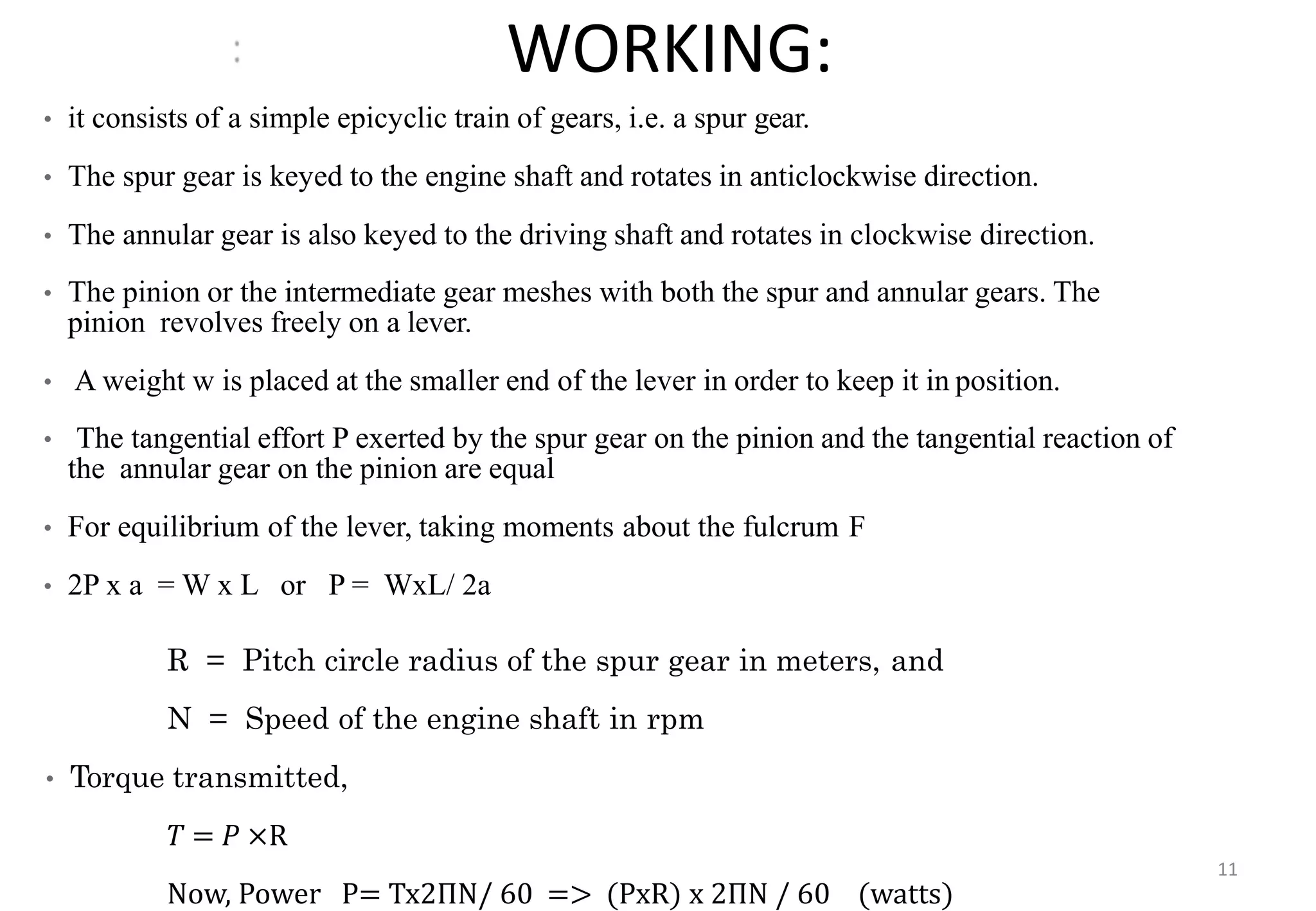

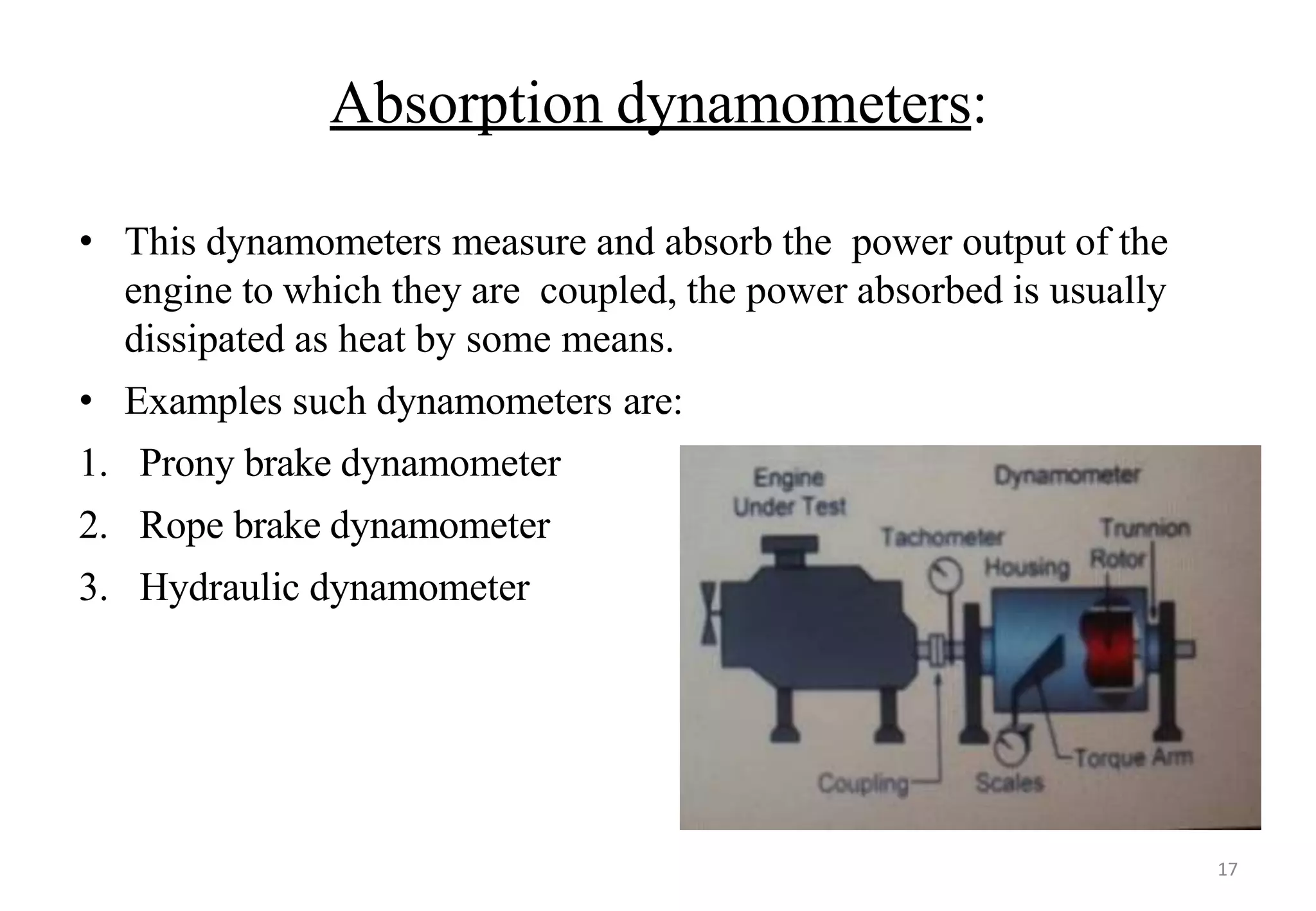

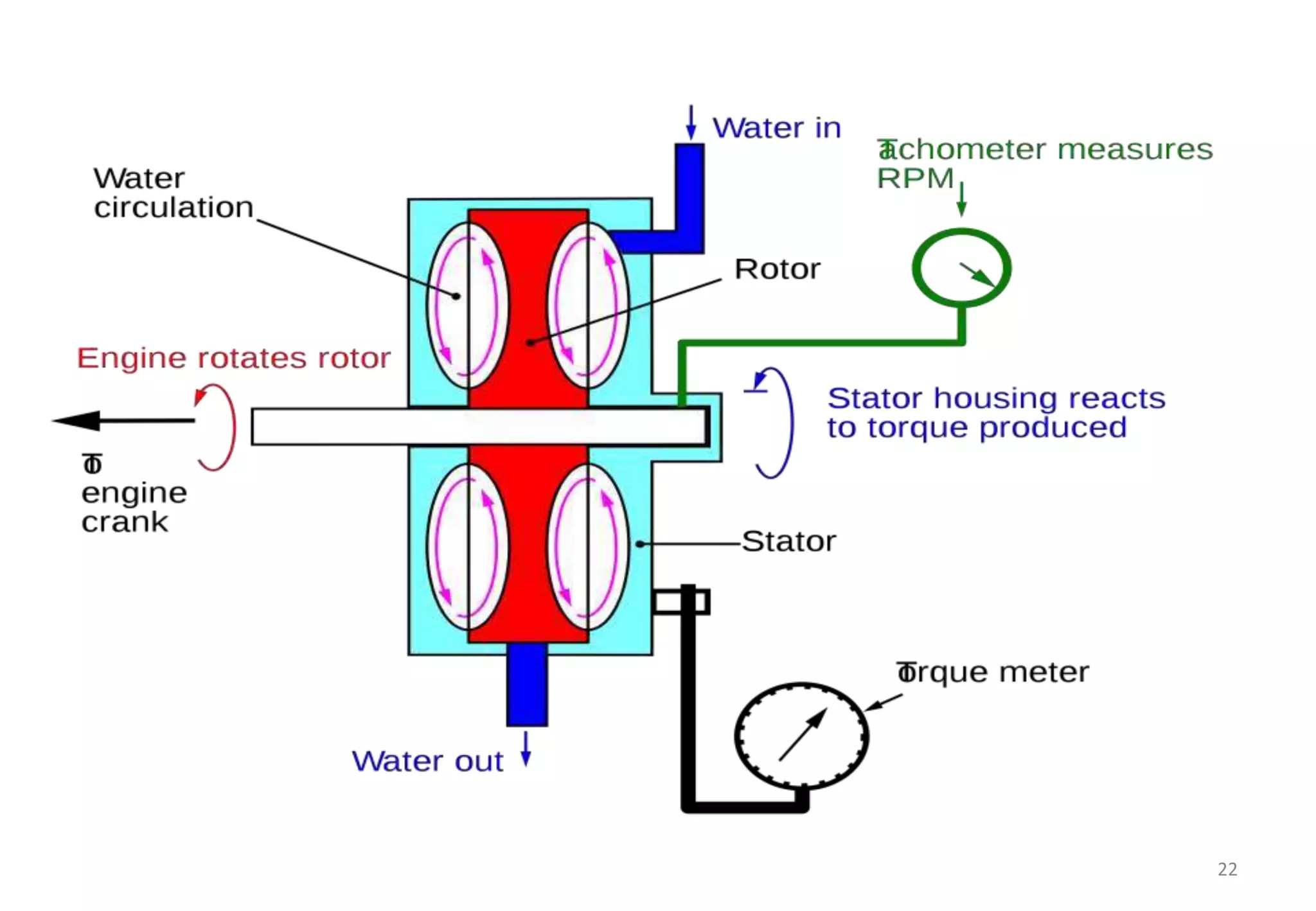

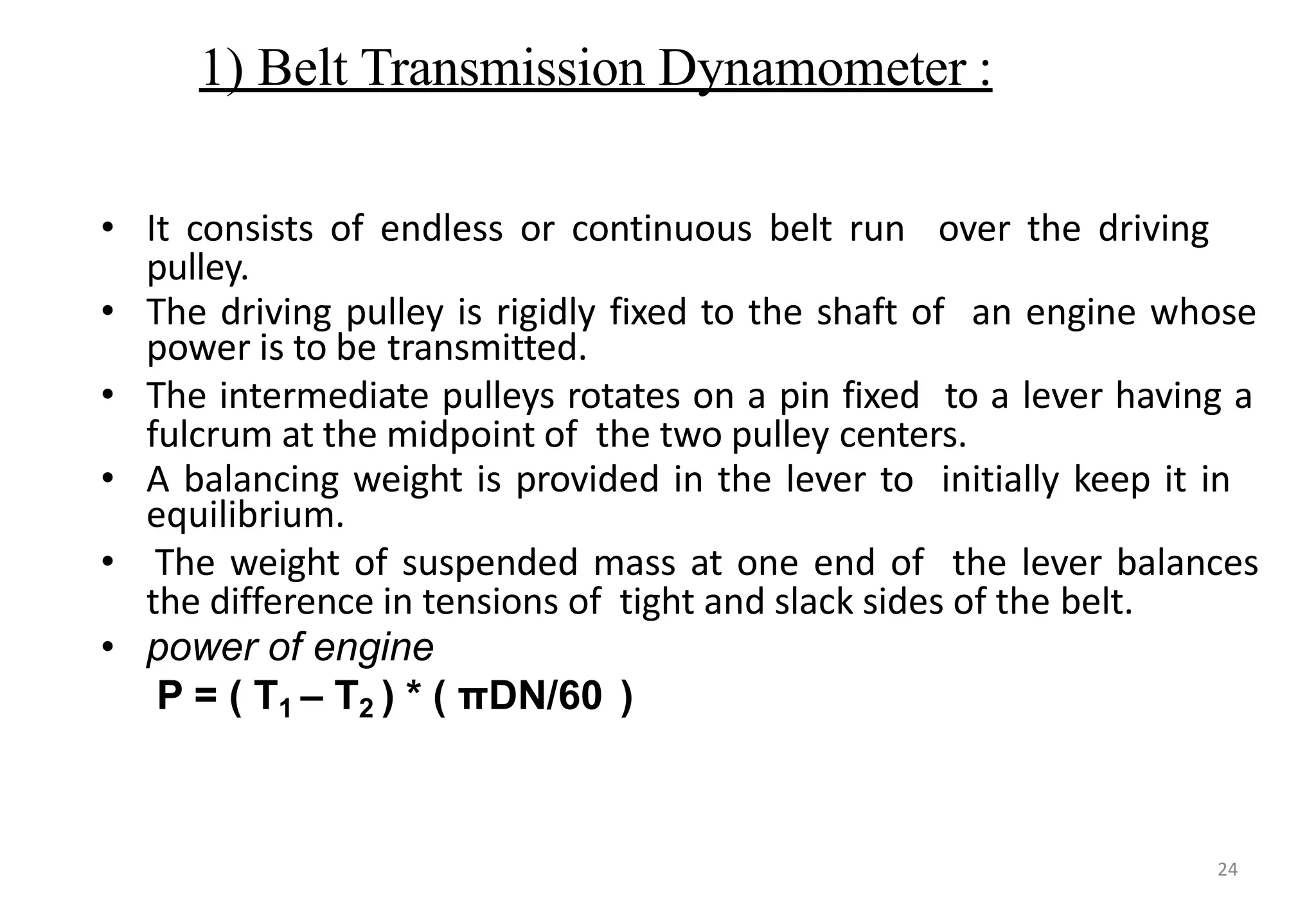

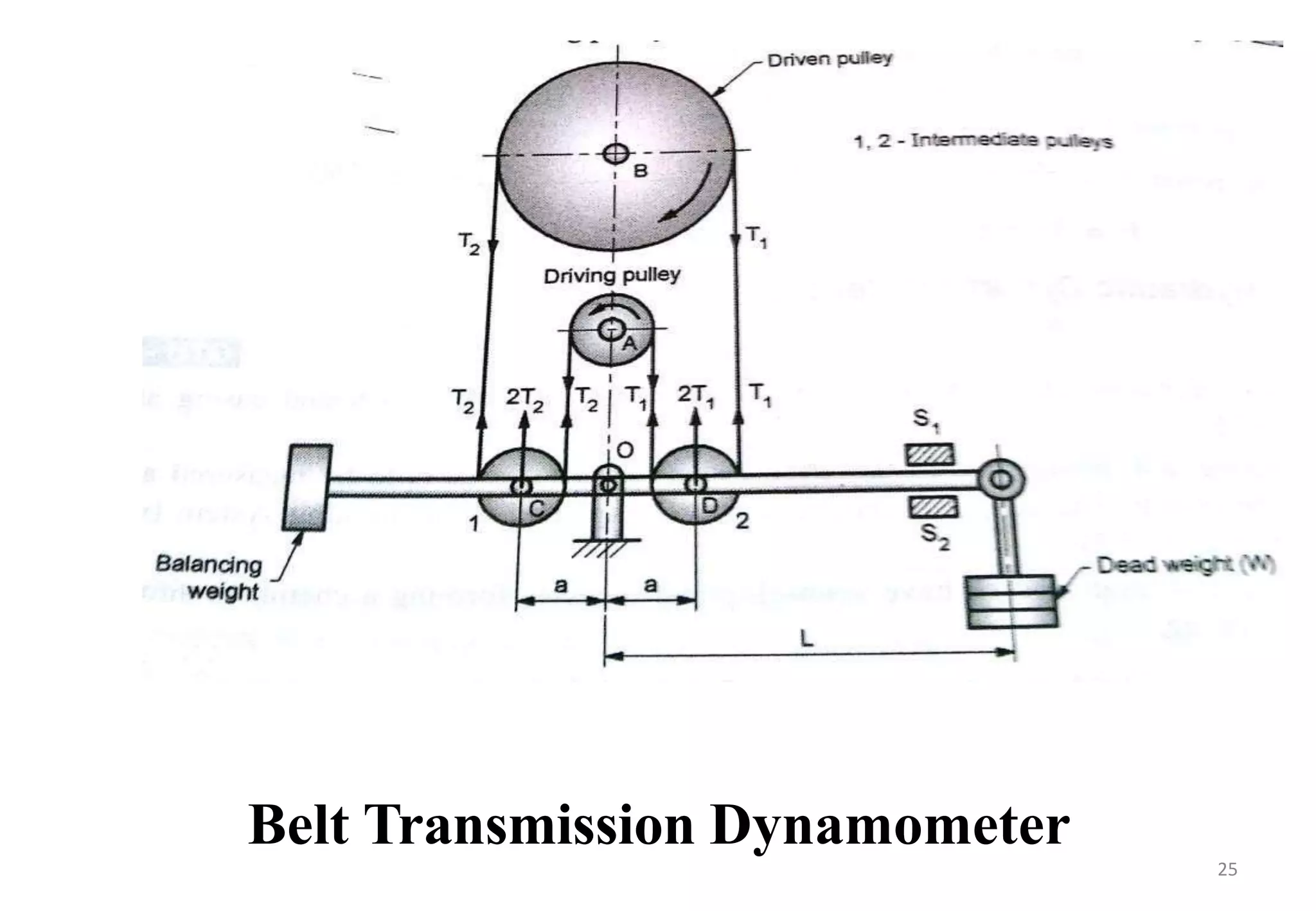

The document discusses different types of dynamometers used for measuring shaft power and torque. It describes absorption dynamometers such as Prony brakes, rope brakes, and hydraulic brakes which measure power by absorbing it and dissipating it as heat. It also covers transmission dynamometers like belt dynamometers and epicyclic train dynamometers which measure torque transmitted through the shaft. Specific examples of commonly used dynamometers like the Prony brake and rope brake are explained in detail, outlining their construction, working principles, and power measurement formulas.