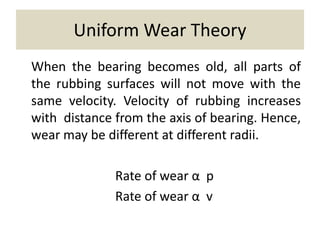

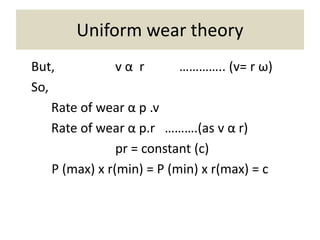

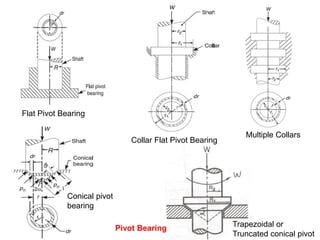

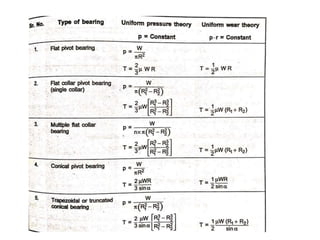

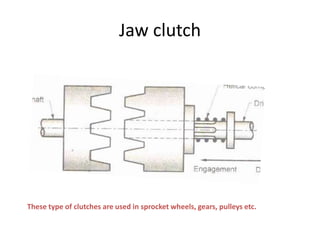

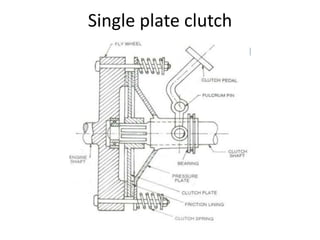

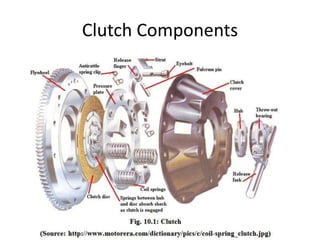

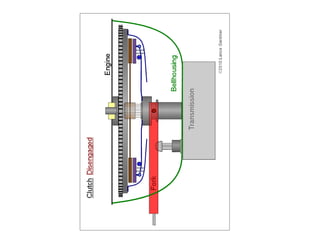

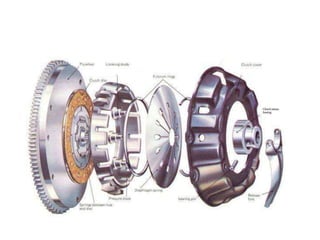

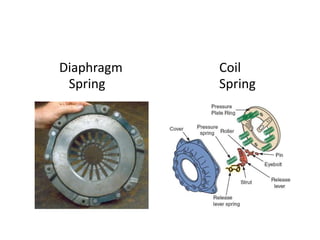

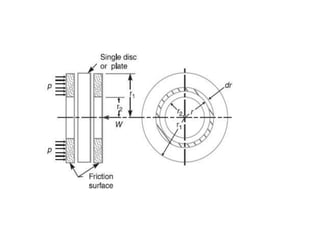

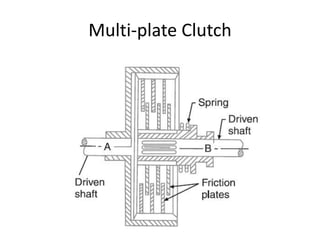

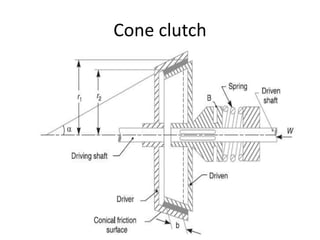

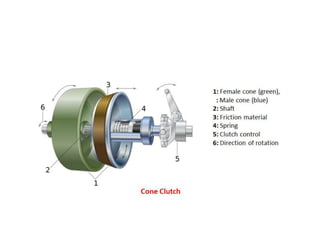

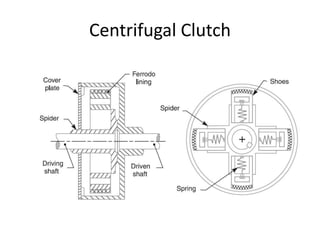

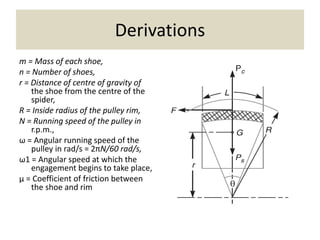

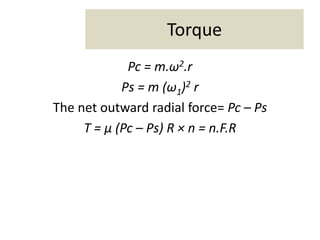

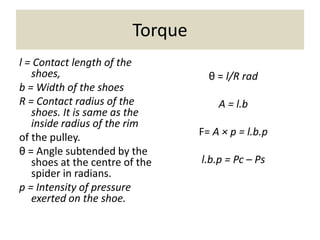

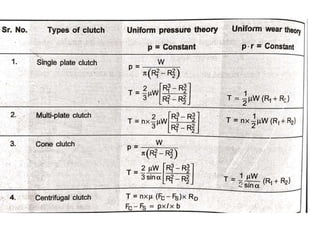

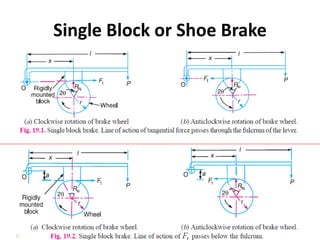

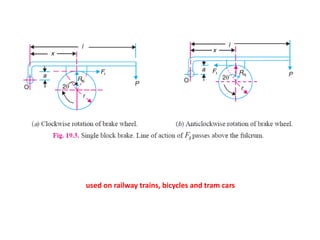

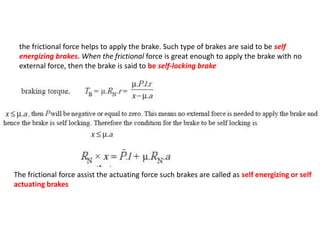

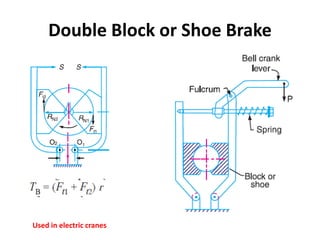

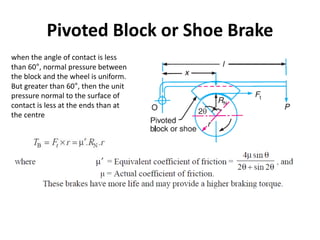

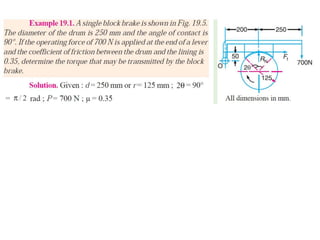

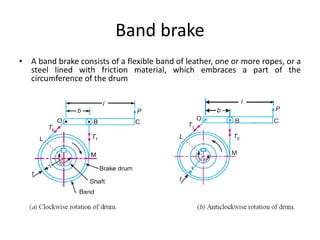

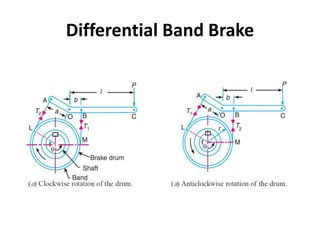

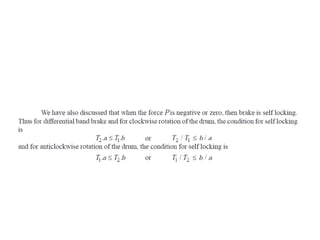

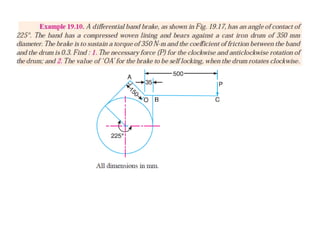

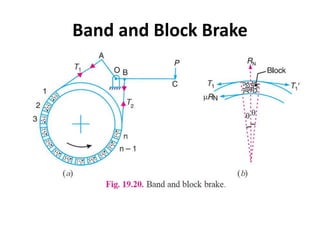

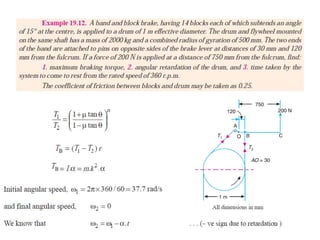

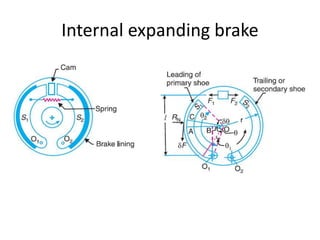

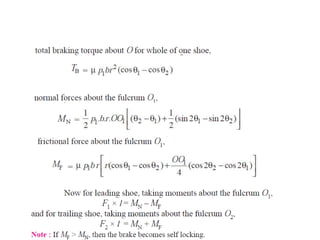

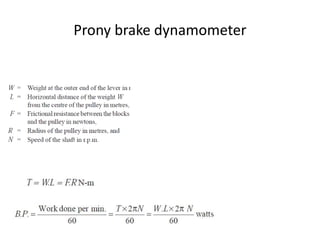

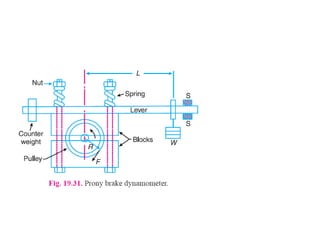

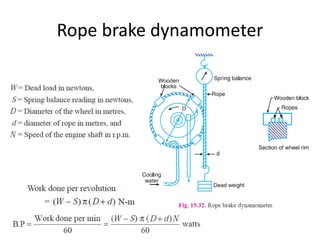

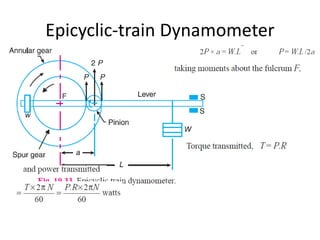

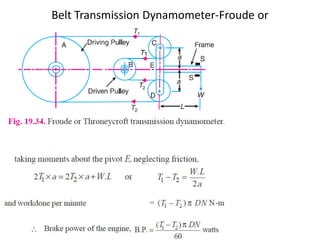

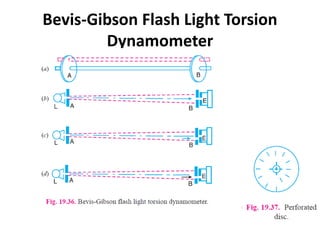

This document discusses clutches, brakes, and dynamometers. It provides theories and types of clutches like plate clutches, cone clutches, and centrifugal clutches. It also discusses different types of brakes such as shoe brakes, band brakes, block brakes, and disc brakes. Finally, it covers absorption dynamometers including Prony, rope, and band brake dynamometers as well as transmission dynamometers like epicyclic train and belt transmission dynamometers.