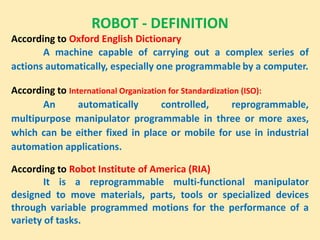

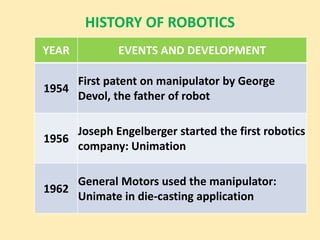

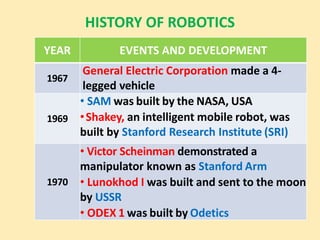

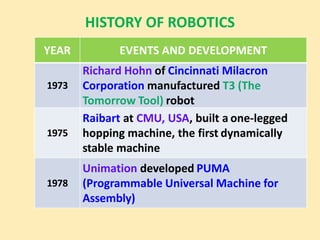

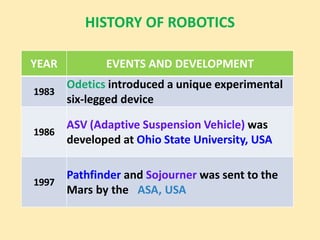

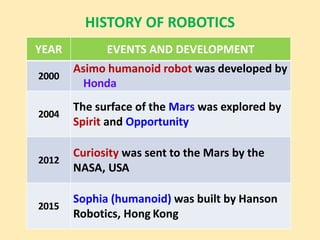

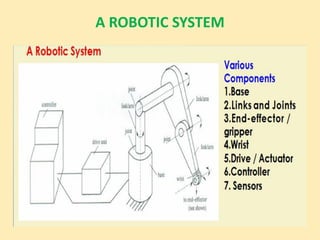

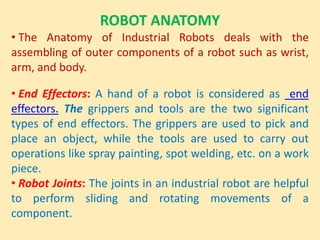

This document provides an introduction to robotics and automation, including definitions of robots, a brief history of robotics, the anatomy and types of robots, how robots are classified, robot specifications, applications of robots, the role of robots in addressing societal problems, and issues around the future of automation. Key topics covered include definitions of robots from various organizations, the components that make up a robotic system, how robots have evolved over time, common ways robots are categorized, their use in fields like manufacturing, medicine, agriculture and more, as well as both benefits and ethical concerns regarding increased automation.