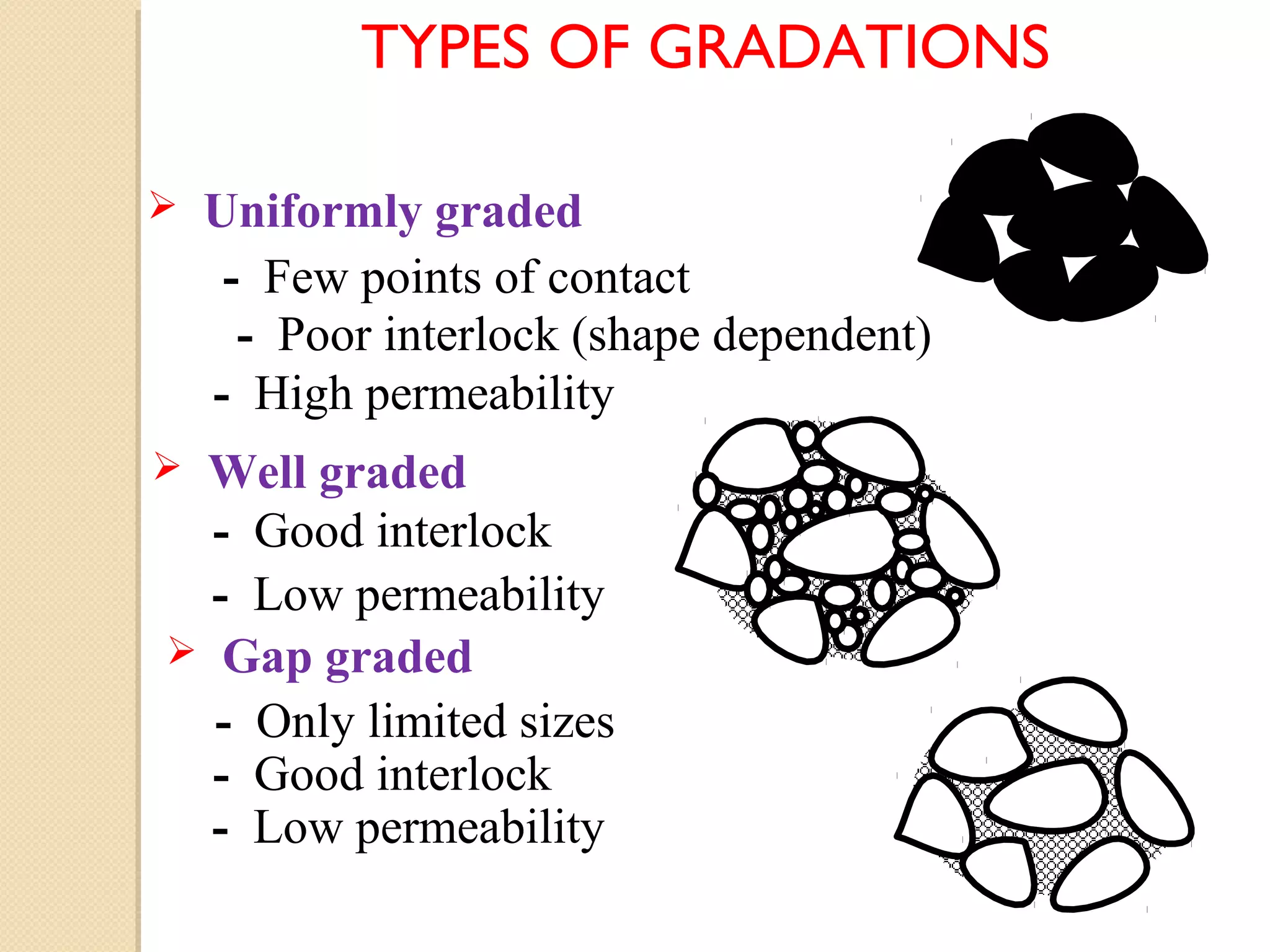

The document discusses various materials used in pavement construction including road aggregates, subbase, and base course materials. It describes desirable properties for road aggregates including resistance to crushing, abrasion, impact, and weathering. It explains that a subbase layer provides a cost-effective way to build thick pavements and can consist of select gravels or stabilized soils. A base course improves load distribution and support. The document also discusses soil-aggregate mix properties, grading requirements, and construction considerations for pavement materials.